Resume Worded | Proven Resume Examples

- Resume Examples

- Engineering Resumes

- Project Engineer Resume Guide & Examples

Process Engineer Resume Examples: Proven To Get You Hired In 2024

Jump to a template:

- Process Engineer

- Manufacturing Process Engineer

- Chemical Process Engineer

Get advice on each section of your resume:

Jump to a resource:

- Process Engineer Resume Tips

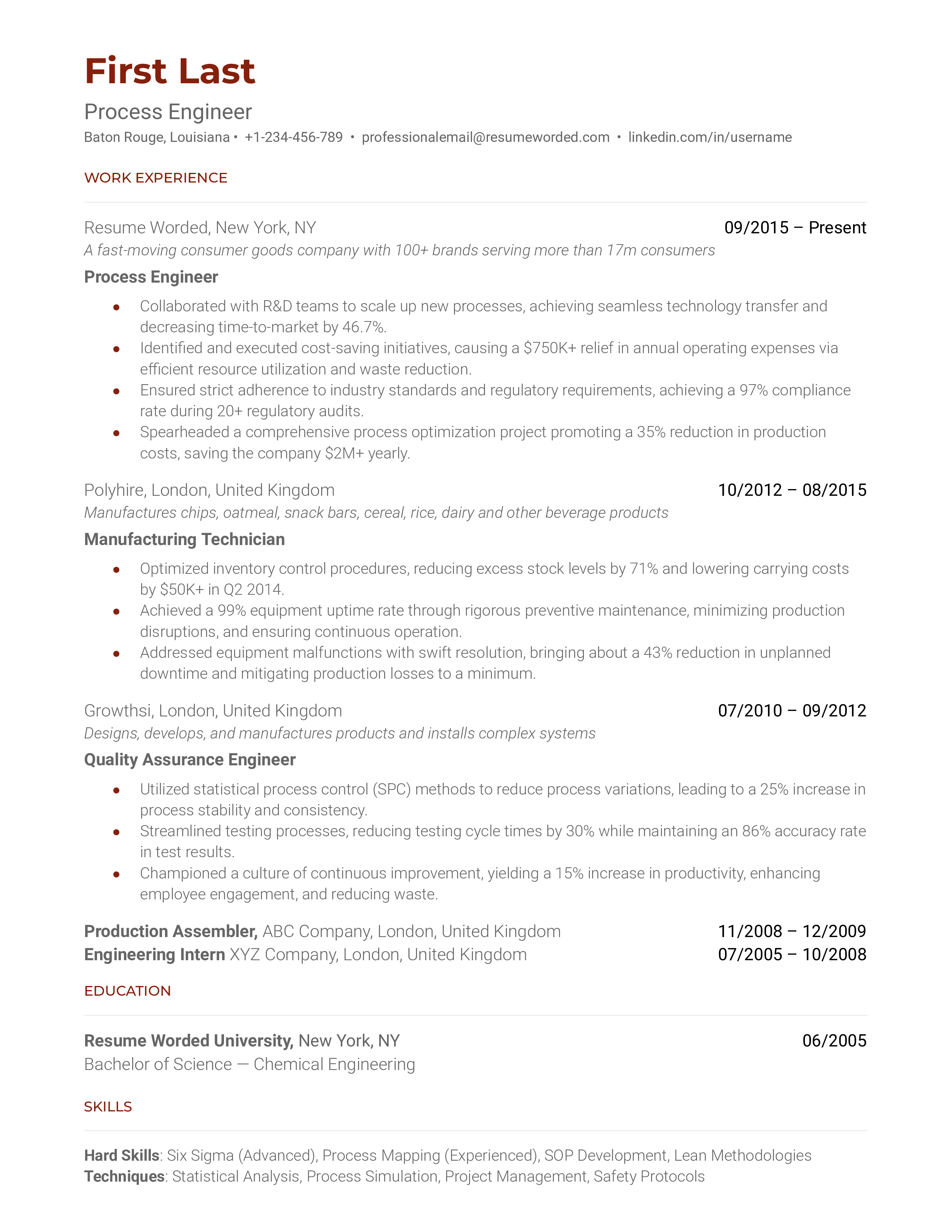

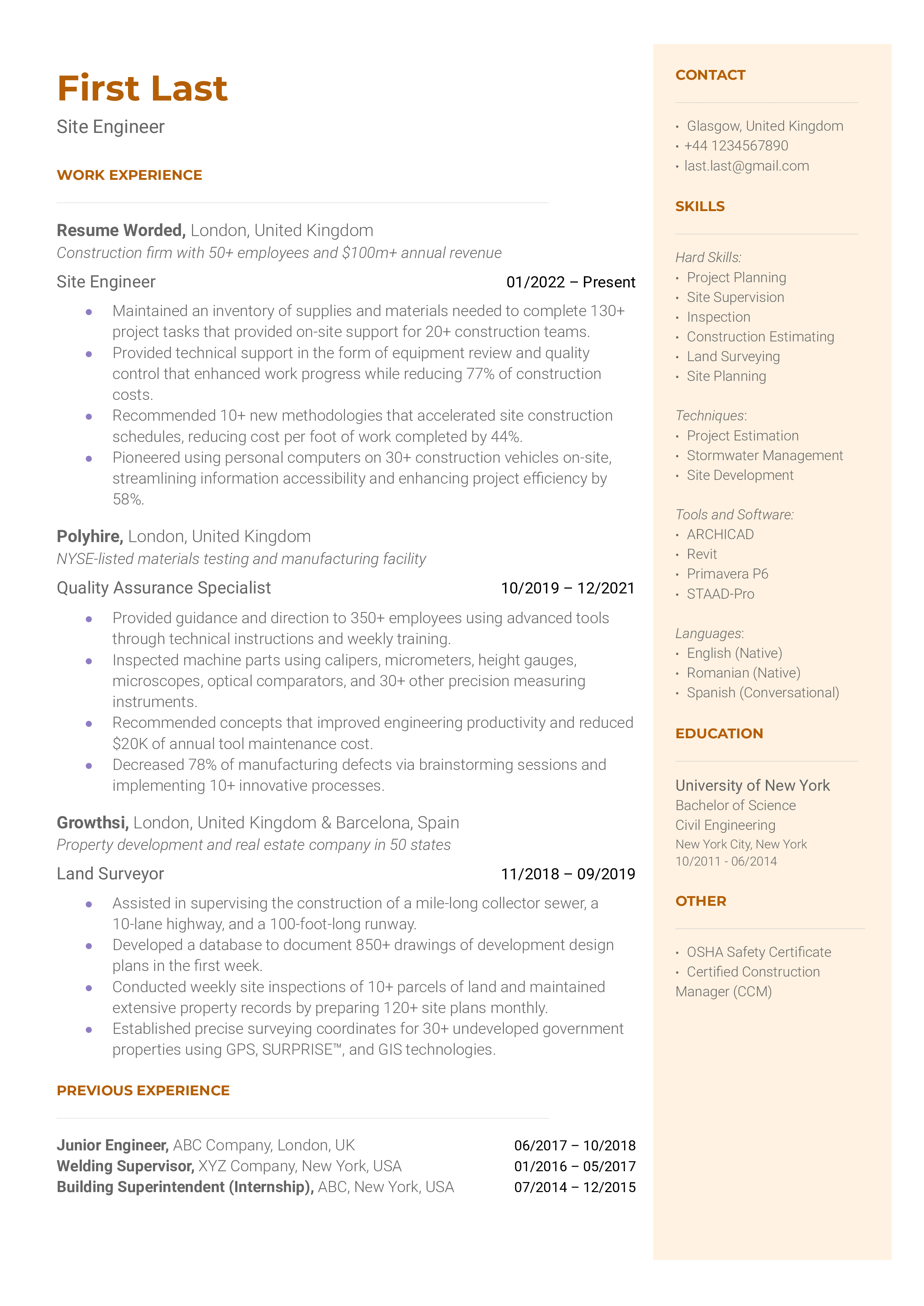

Process Engineer Resume Template

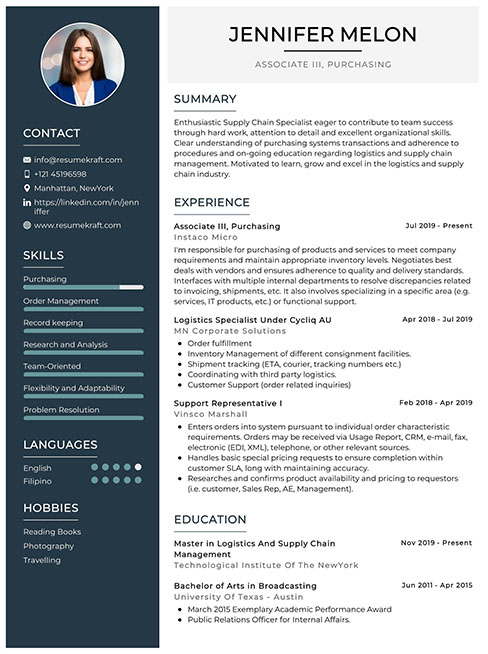

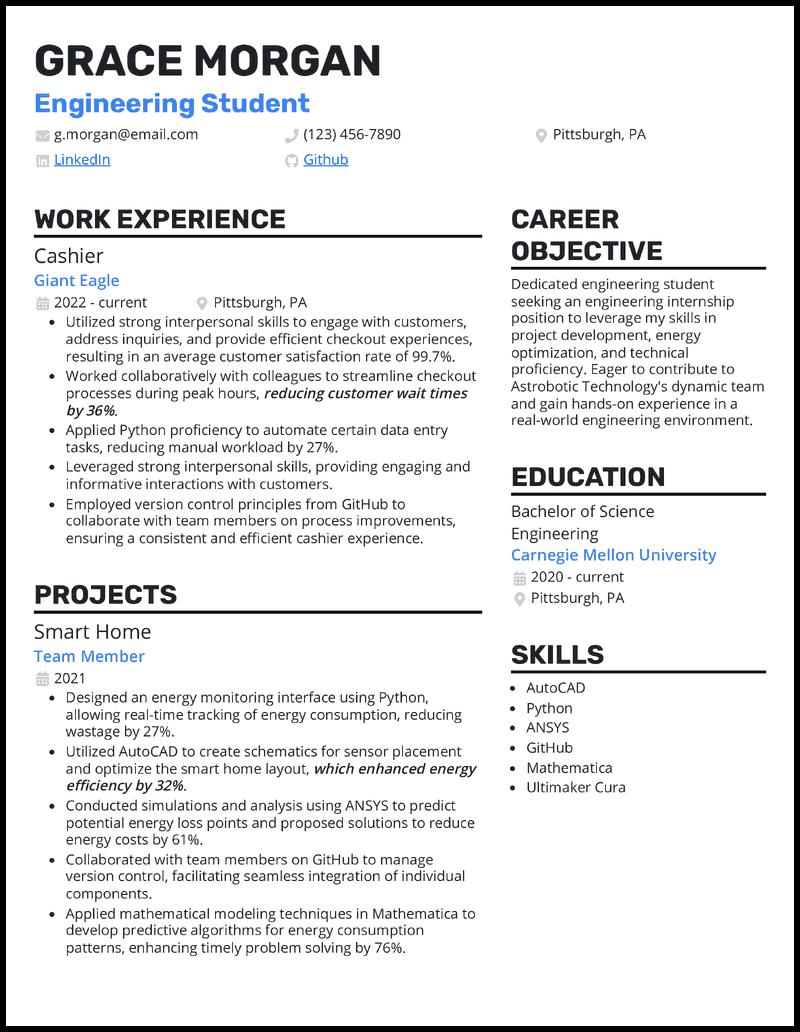

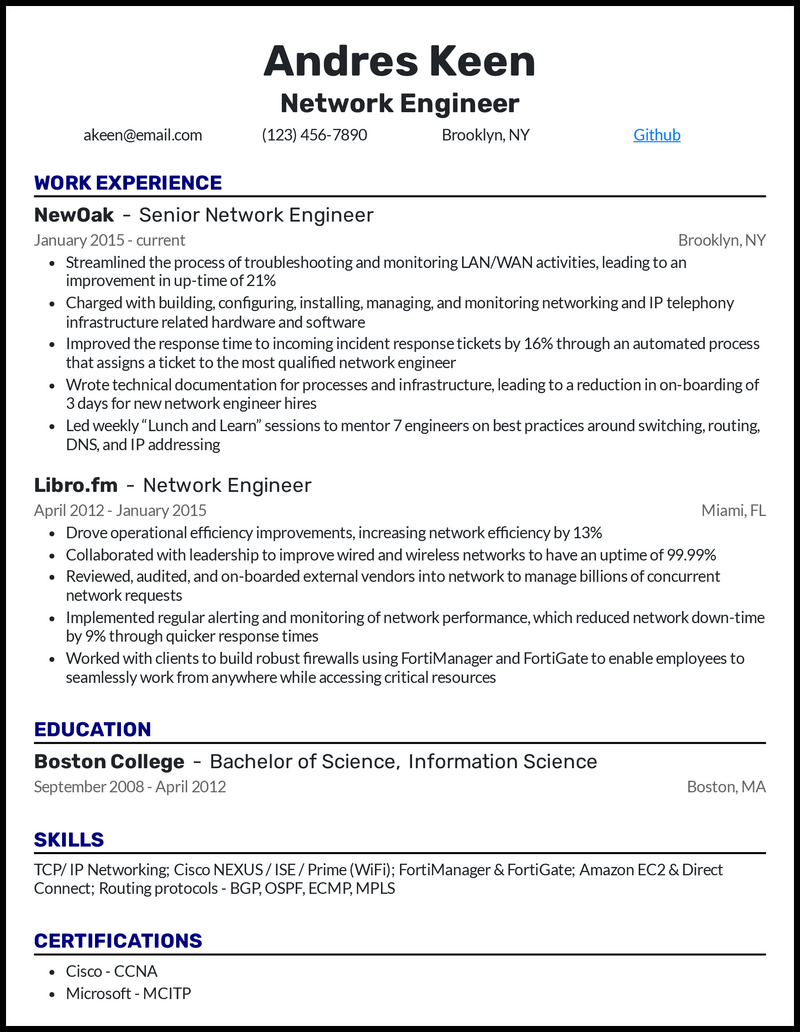

Download in google doc, word or pdf for free. designed to pass resume screening software in 2022., process engineer resume sample.

Ah, being a Process Engineer! It isn't just about being knee-deep in technical details, but also about understanding the entire systemic flow within industrial processes. Your resume is about showcasing your ability to identify, develop, and execute process improvements to increase productivity, safety, and cost-efficiency. And remember, companies recently aren't just looking for engineers who can just "keep the machine running"; nowadays, they want innovative thinkers who can pivot quickly in this fast-paced, technology-driven world. So, when tailoring your resume, it's not just about listing your technical knowledge and skills. Really focus on your knack for problem-solving, your ability to make informed decisions and your capacity to spearhead changes. Show them that you're not just an engineer, but a leader in disguise.

We're just getting the template ready for you, just a second left.

Recruiter Insight: Why this resume works in 2022

Tips to help you write your process engineer resume in 2024, show your ability to innovate.

Engineering is often thought of as a purely technical field, but as a process engineer, you're expected to be a creative problem solver. On your resume, detail specific instances where you've introduced new processes or adapted existing ones, making sure to quantify the impact these changes had.

Evidence of technical skills and knowledge

It's crucial that your resume proves you've got the chops when it comes to the technical side of things. You can do this by discussing projects you've handled and the specific methodologies or technologies you used. Just keep the jargon to a minimum so the hiring manager can understand.

As a process engineer, you're the keystone in the company's effort to make production lines efficient and reliable. Your unique blend of technical know-how and problem-solving acumen is what keeps everything running smoothly. The world's turning more and more towards automated systems, and companies need folks like you to ensure these systems operate at their best. When writing your resume, it's critical to convey not only your technical prowess but also your ability to analyze and optimize processes. In the past few years, we've seen companies increasingly valuing process engineers who complement their technical skills with strong interpersonal capabilities. It's not just about tweaking machines anymore; it's also about communicating changes and training others to adapt. So, your resume needs to tell a story that balances these two sides of your role.

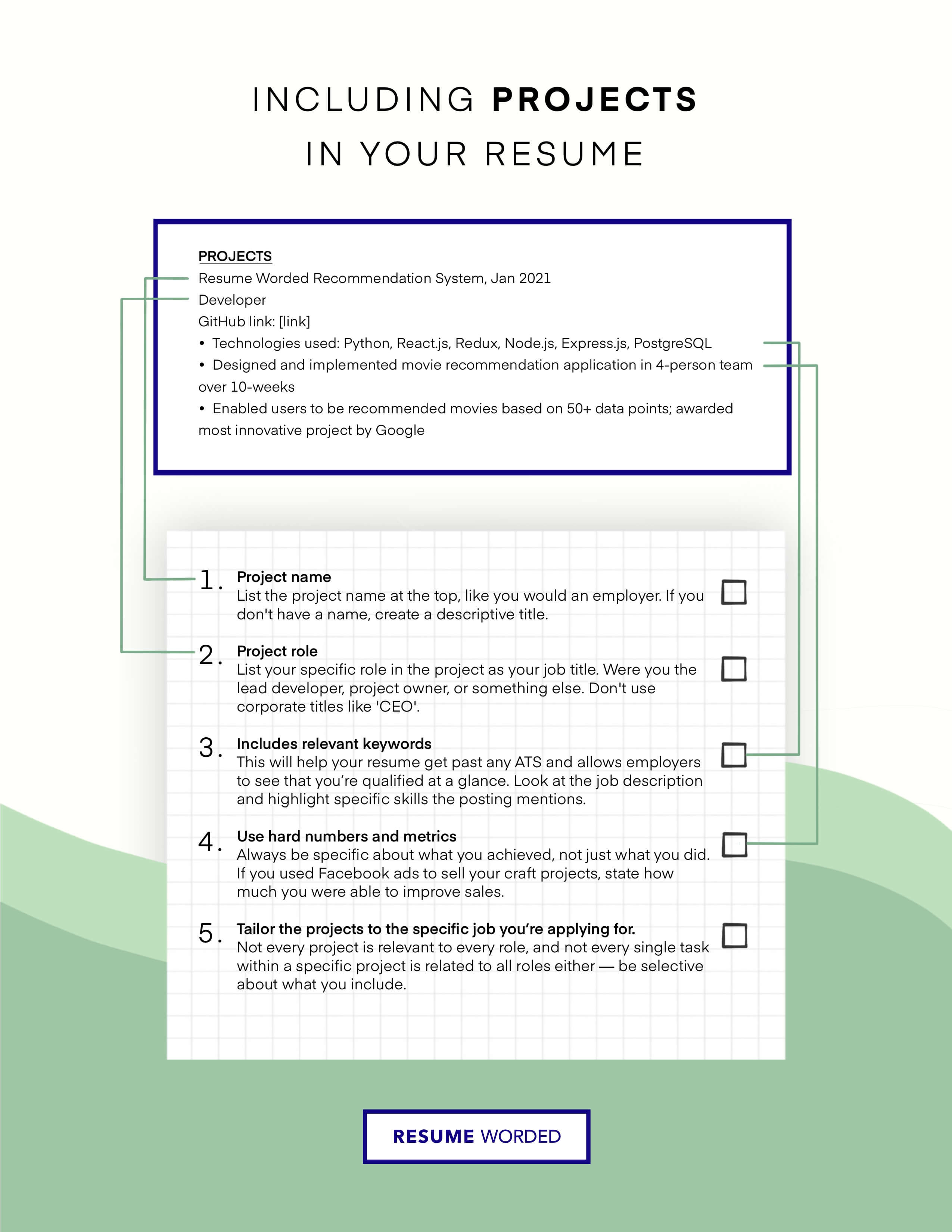

Include a projects section

As a process engineer, you've likely overseen a number of projects aimed at improving efficiency or quality. Detail these in a dedicated section on your resume, discussing the challenge, the solution, and the impact.

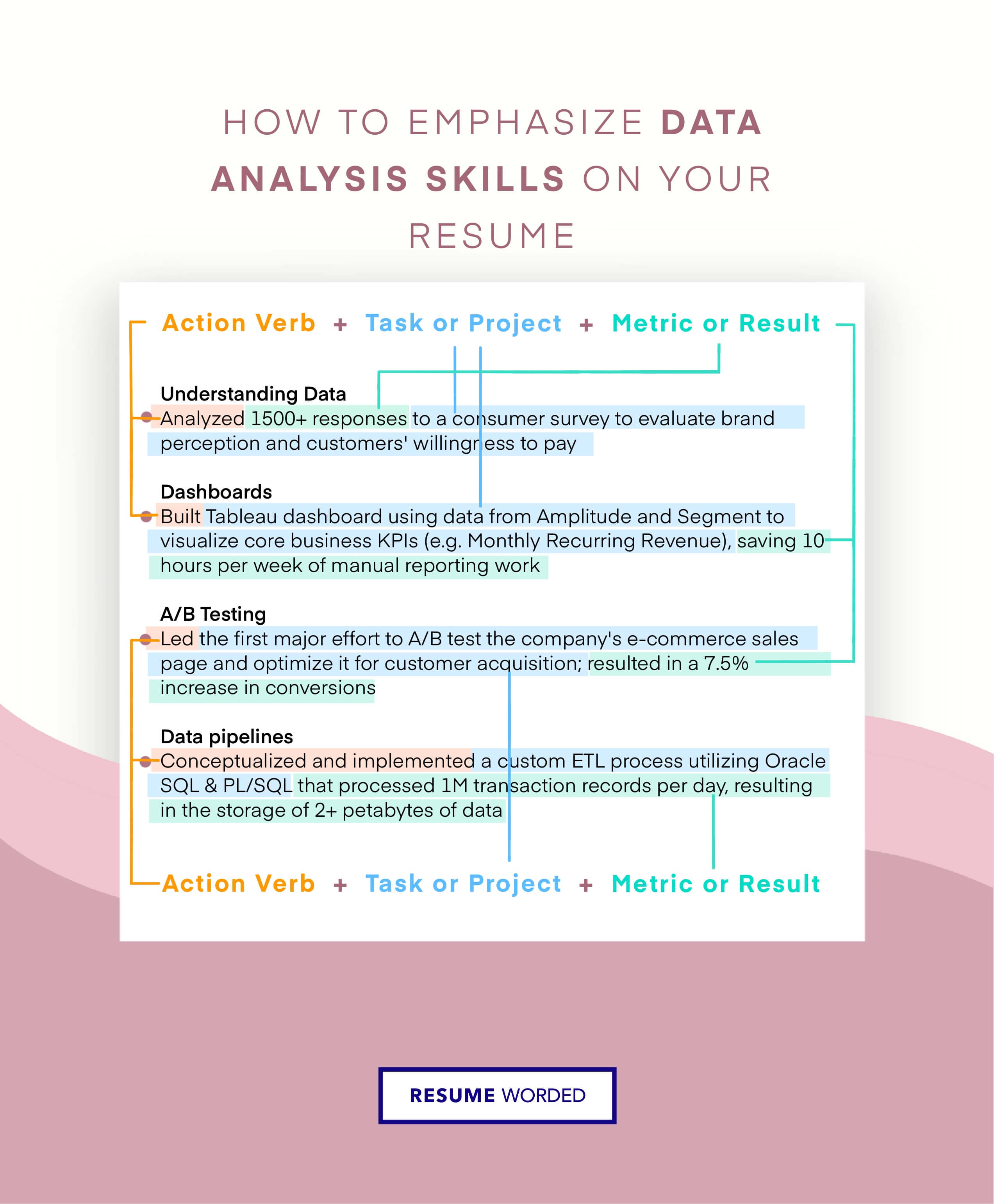

Stress your data analysis skills

In a world of IoT and smart factories, a process engineer's ability to collect and analyze machine data is golden. Demonstrate experience with specific data analysis tools and scenarios where your insights led to process improvements.

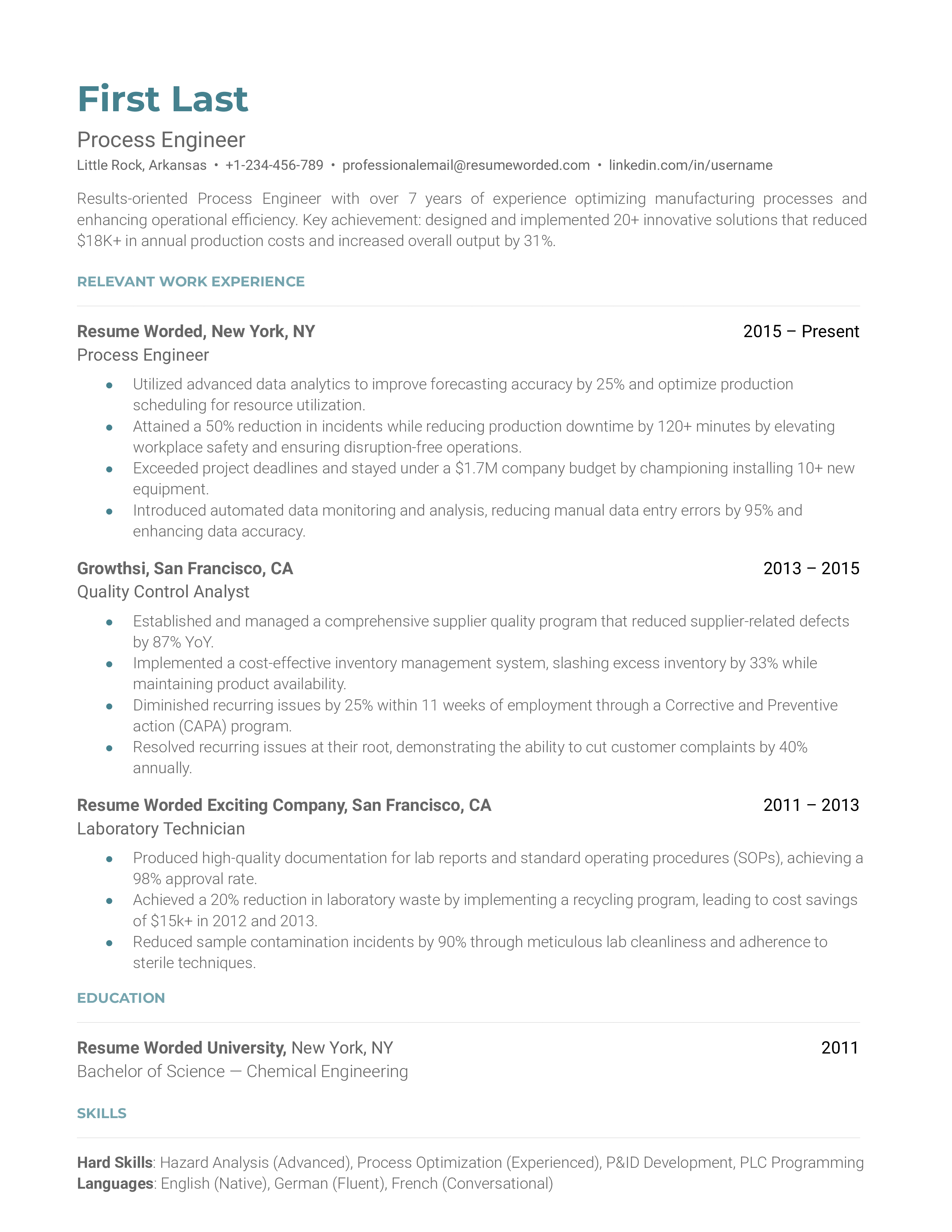

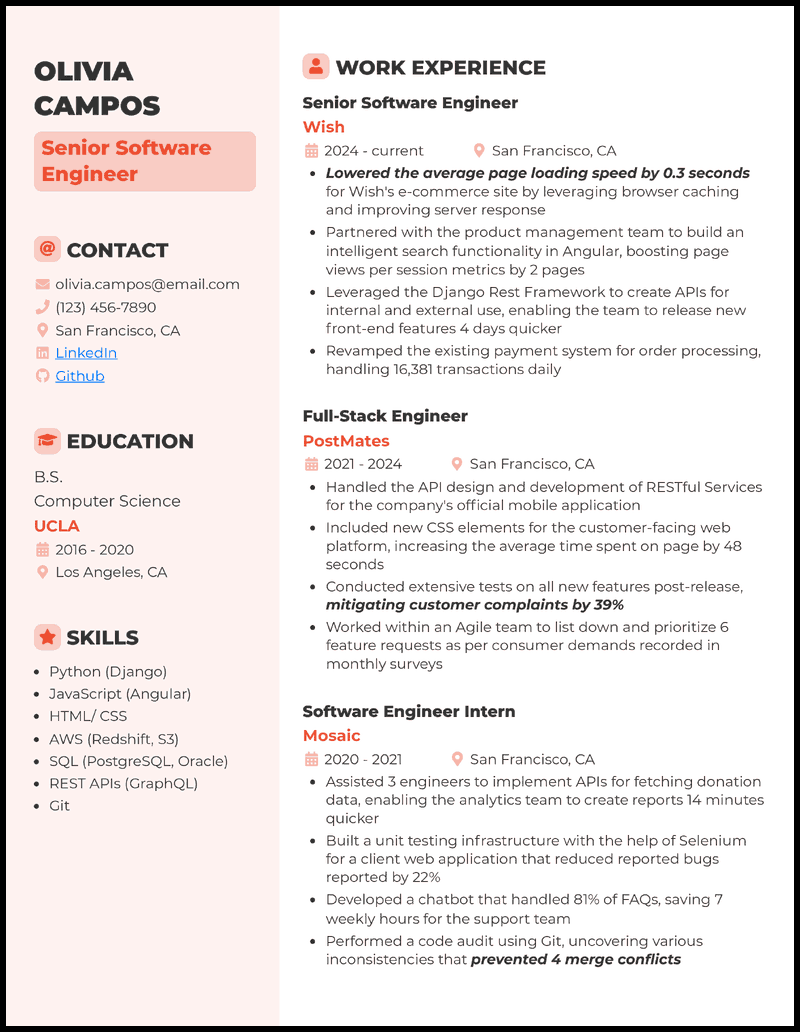

Manufacturing Process Engineer Resume Sample

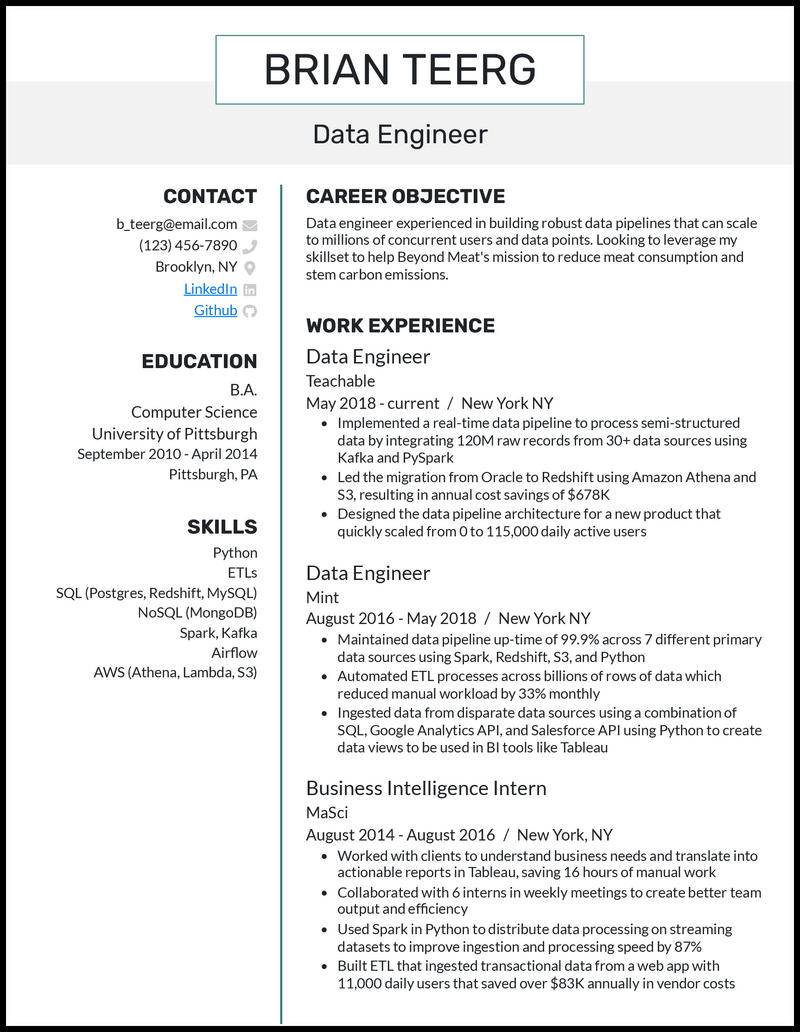

Chemical process engineer resume sample.

We spoke with hiring managers at top manufacturing and engineering companies like General Electric, Boeing, and 3M to understand what they look for in process engineer resumes. Based on their insights, here are 6 tips to help your process engineer resume stand out and increase your chances of landing an interview.

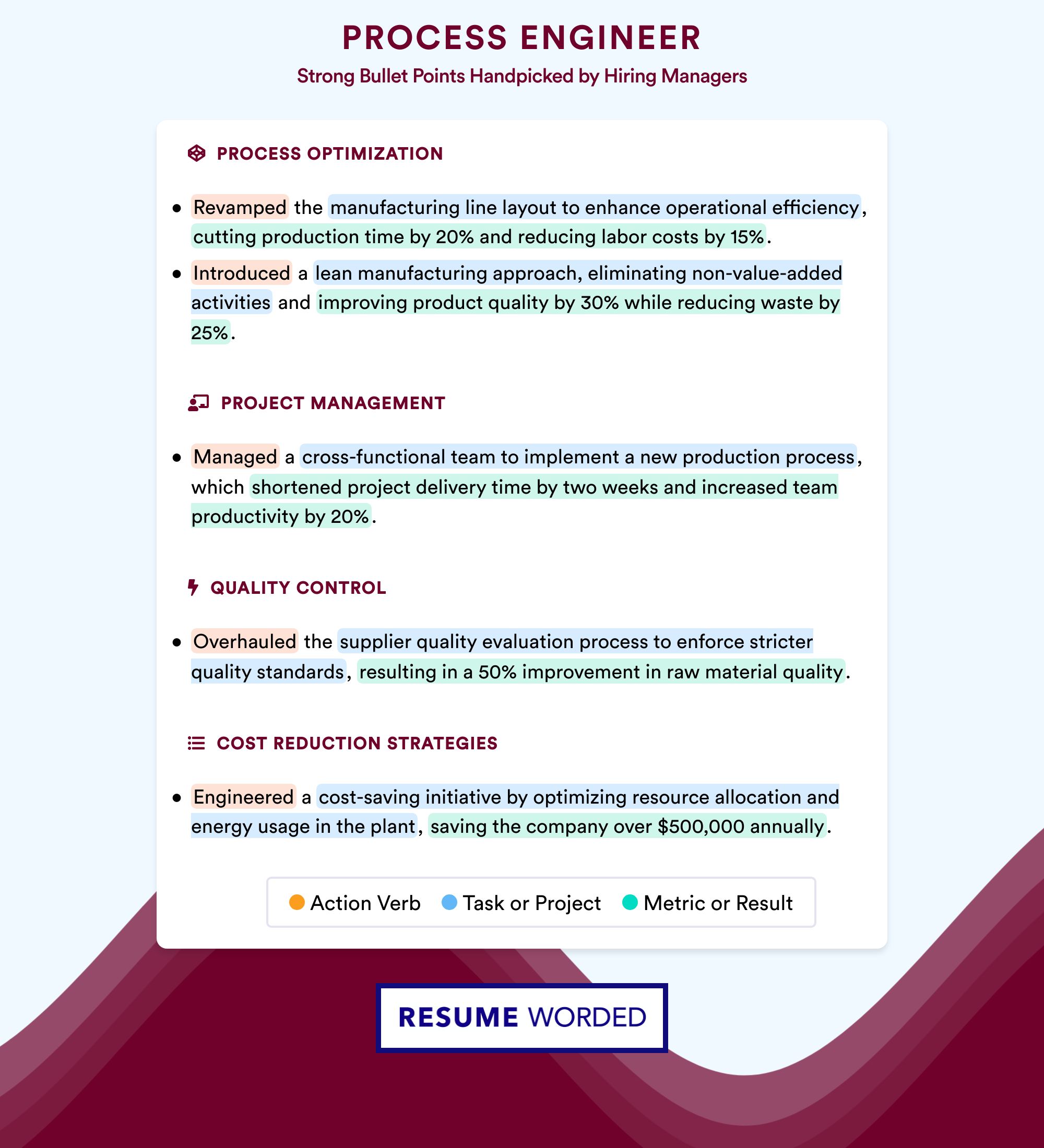

Highlight your process improvement experience

Companies want to see how you have improved processes in your previous roles. Instead of simply listing your responsibilities, focus on the impact you made:

- Responsible for analyzing and improving manufacturing processes

Quantify the results of your process improvements, like this:

- Analyzed and optimized manufacturing processes, resulting in a 15% reduction in cycle time and $200K in annual cost savings

- Led a Six Sigma project that increased production yield by 10% and reduced defects by 25%

Showcase your technical skills

Process engineers need a strong foundation in various technical skills. Highlight your proficiency in areas such as:

- Lean manufacturing

- Six Sigma (include your belt level)

- Statistical process control (SPC)

- Process simulation software (e.g., Arena, Simul8)

- AutoCAD and other relevant engineering software

Also, provide examples of how you applied these skills:

Utilized Lean manufacturing principles to streamline assembly line processes, reducing waste by 20% and increasing output by 15%.

Demonstrate your problem-solving abilities

Employers want to see how you tackle challenges. Share examples of complex problems you solved and the outcomes you achieved. A weak example would be:

- Solved production issues to improve efficiency

Instead, provide specific details and results:

- Investigated and resolved a bottleneck in the production line, resulting in a 25% increase in daily output

- Developed and implemented a solution to reduce machine downtime by 30%, saving the company $150K annually

Include relevant projects and initiatives

Showcase any projects or initiatives you led that had a significant impact on the organization. This could include:

- Implementing new technologies or processes

- Leading cost reduction efforts

- Spearheading quality improvement initiatives

Initiated and led a waste reduction project that decreased material waste by 15% and saved the company $75K in raw material costs within the first year.

Tailor your resume to the job description

Customize your resume for each job application. Review the job posting and identify the key skills and experience the employer is seeking. Then, prioritize those qualifications in your resume. For example:

- Proficient in AutoCAD, Lean manufacturing, and Six Sigma

If the job description emphasizes experience with specific process improvement methodologies, tailor your skills section accordingly:

- Expertise in Lean manufacturing and Six Sigma (Green Belt certified)

- Skilled in applying DMAIC methodology to improve process efficiency

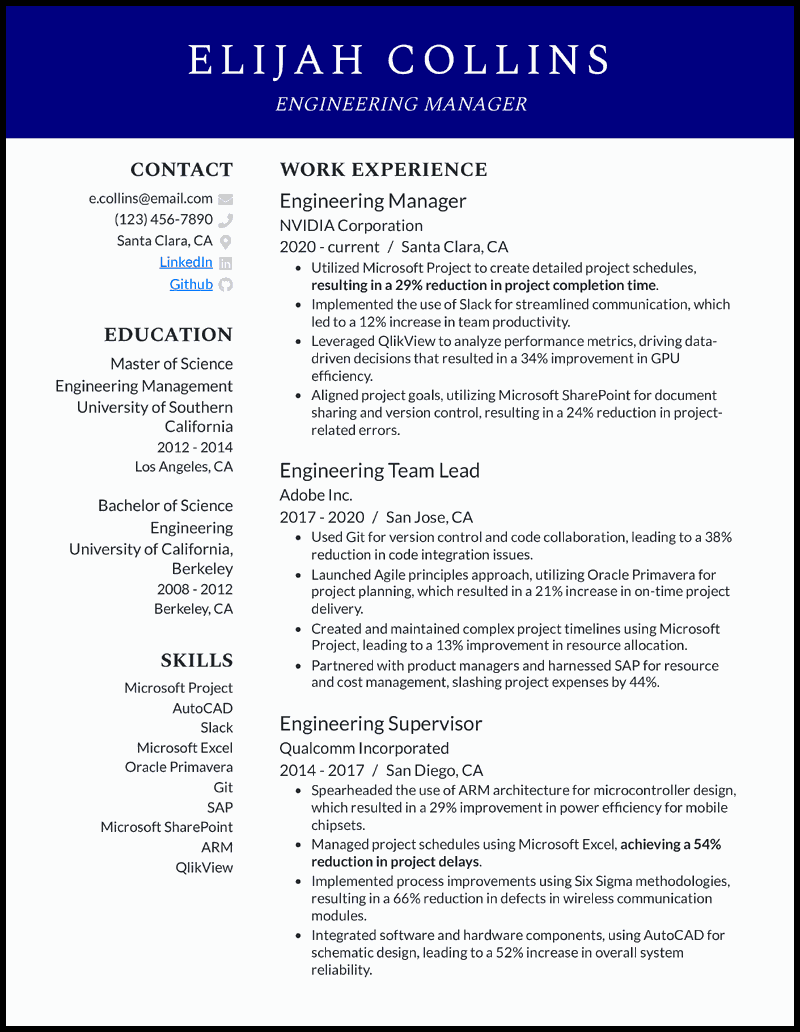

Emphasize your communication and leadership skills

Process engineers often collaborate with cross-functional teams and stakeholders. Highlight your ability to communicate effectively and lead projects:

- Presented process improvement proposals to senior management, securing approval for implementation

- Collaborated with cross-functional teams (manufacturing, quality, R&D) to develop and implement process enhancements

- Trained and mentored junior engineers on Lean manufacturing principles and techniques

By showcasing your communication and leadership skills, you demonstrate your ability to drive change and work effectively with others.

Writing Your Process Engineer Resume: Section By Section

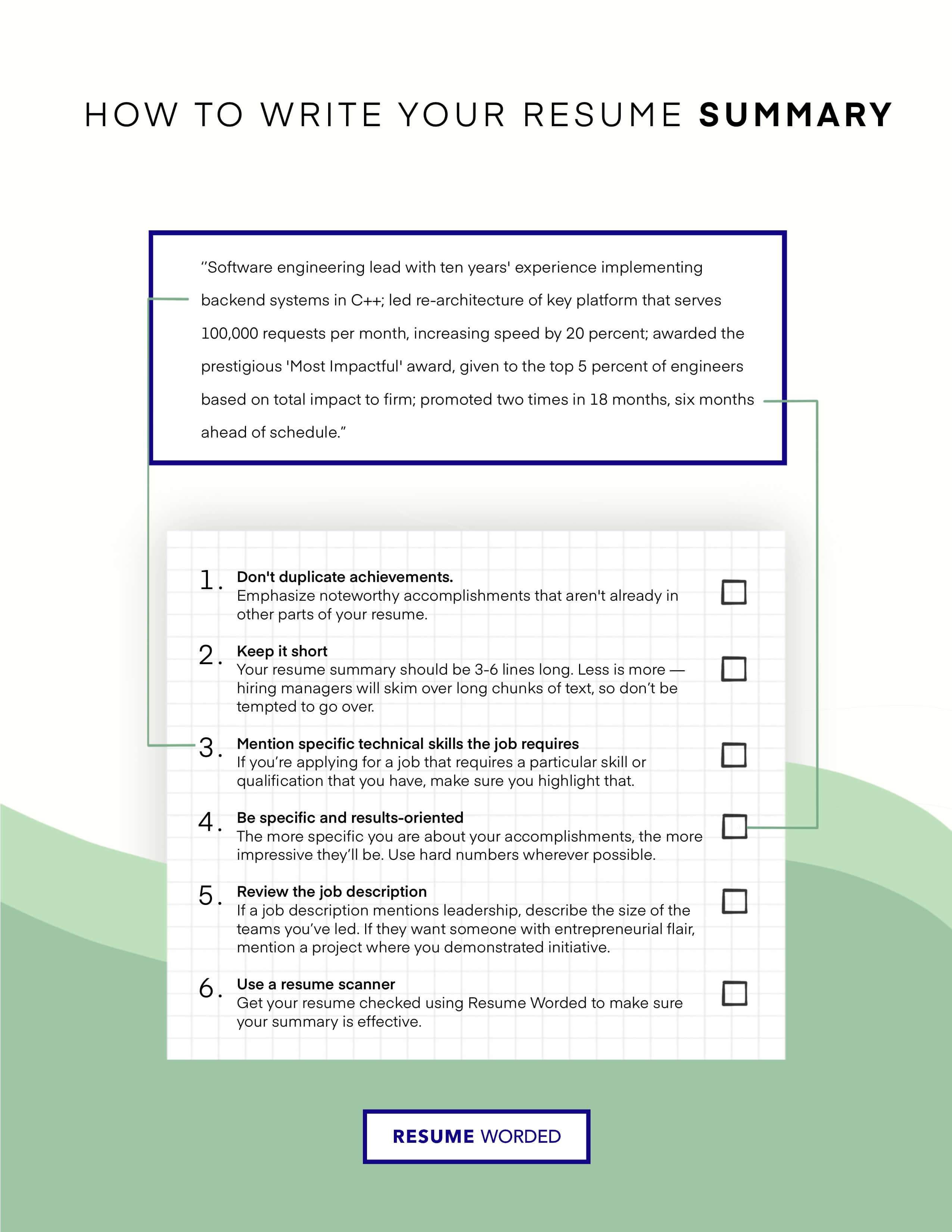

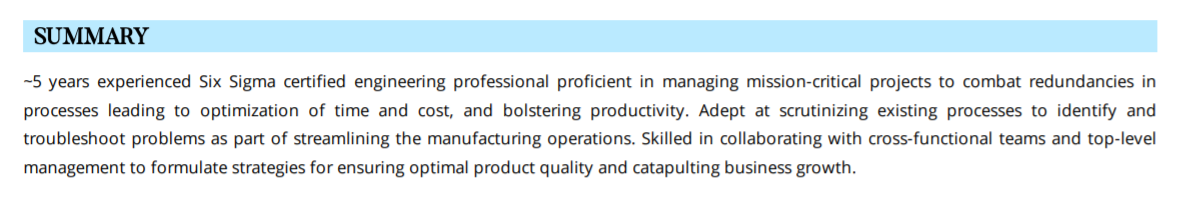

summary.

As a process engineer, your resume summary is an optional section that can help provide additional context about your skills and experience. While your resume itself should already be a concise summary of your qualifications, a well-written summary can be particularly useful if you're changing careers or have a lot of relevant experience to highlight.

However, it's important to avoid using an objective statement, which is an outdated resume format that focuses on what you want rather than what you can offer an employer. Instead, use your summary to showcase your most relevant skills, experience, and achievements in a way that aligns with the job description.

To learn how to write an effective resume summary for your Process Engineer resume, or figure out if you need one, please read Process Engineer Resume Summary Examples , or Process Engineer Resume Objective Examples .

1. Tailor your summary to the process engineer role

When writing your summary, make sure to focus on the specific skills and experience that are most relevant to the process engineer position you're applying for. This may include:

- Your experience optimizing and improving manufacturing processes

- Your knowledge of process control systems and quality assurance methods

- Your ability to analyze data and identify areas for improvement

By tailoring your summary to the specific requirements of the job, you'll show the hiring manager that you're a strong fit for the role. For example:

Process engineer with 5+ years of experience optimizing manufacturing processes in the automotive industry. Skilled in process control, quality assurance, and data analysis. Proven track record of reducing costs and improving efficiency through process improvements.

2. Quantify your achievements

Whenever possible, use specific numbers and metrics to quantify your achievements in your summary. This helps provide concrete evidence of your skills and experience. For example:

- Experienced process engineer with a track record of improving efficiency

While this summary mentions the candidate's experience and skills, it doesn't provide any specific details. Instead, try something like:

- Process engineer with 7+ years of experience. Implemented process improvements that increased production output by 15% while reducing defects by 10%.

By quantifying their achievements, this candidate provides a clear picture of the impact they've had in their previous roles.

Experience

Your work experience section is the heart of your resume as a process engineer. It's where you showcase your skills and accomplishments from previous roles. Highlight your biggest wins that are most relevant to the jobs you are applying for.

In this section, we'll cover what to include in your work experience section, how to write about your experiences effectively, and mistakes to avoid.

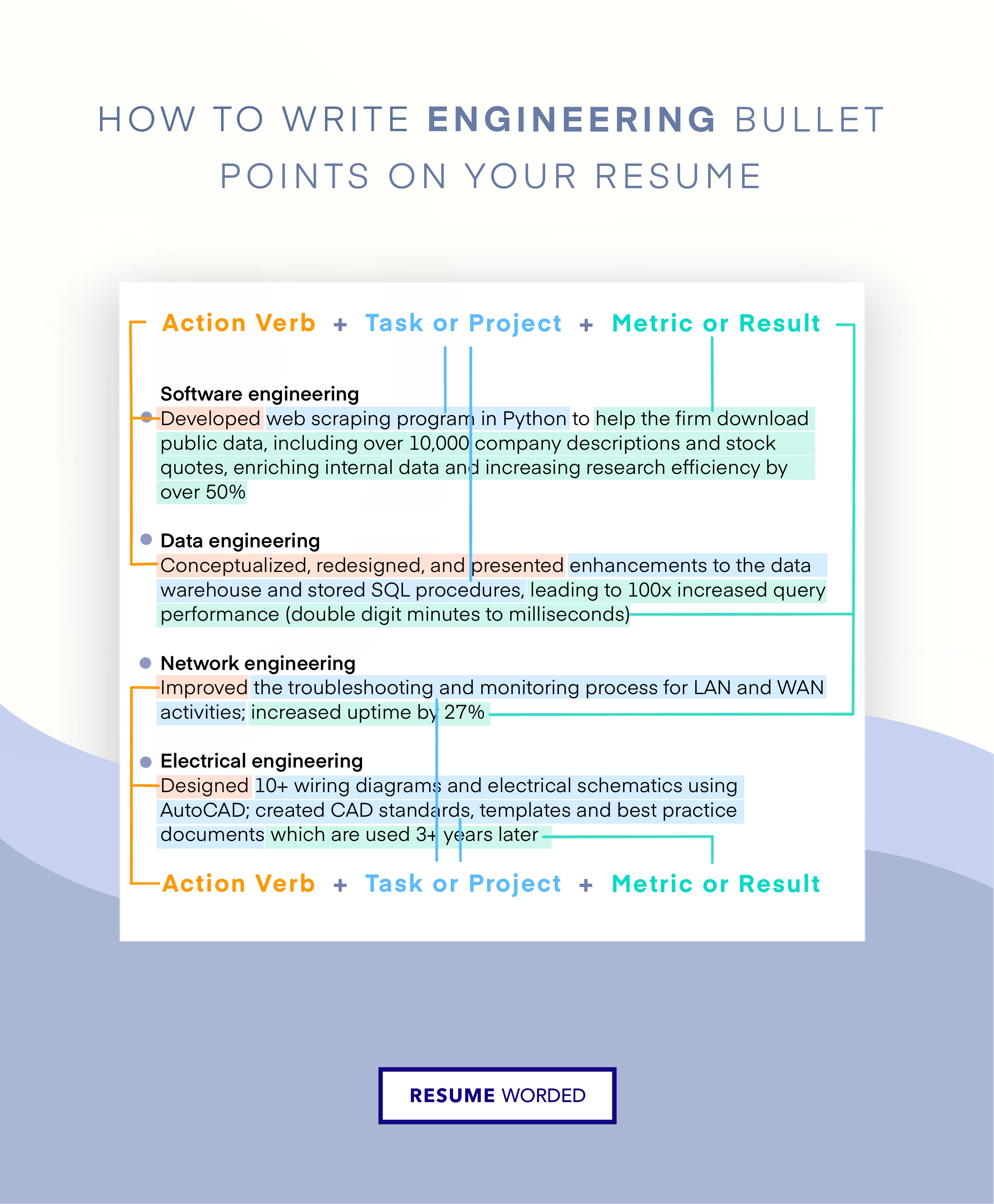

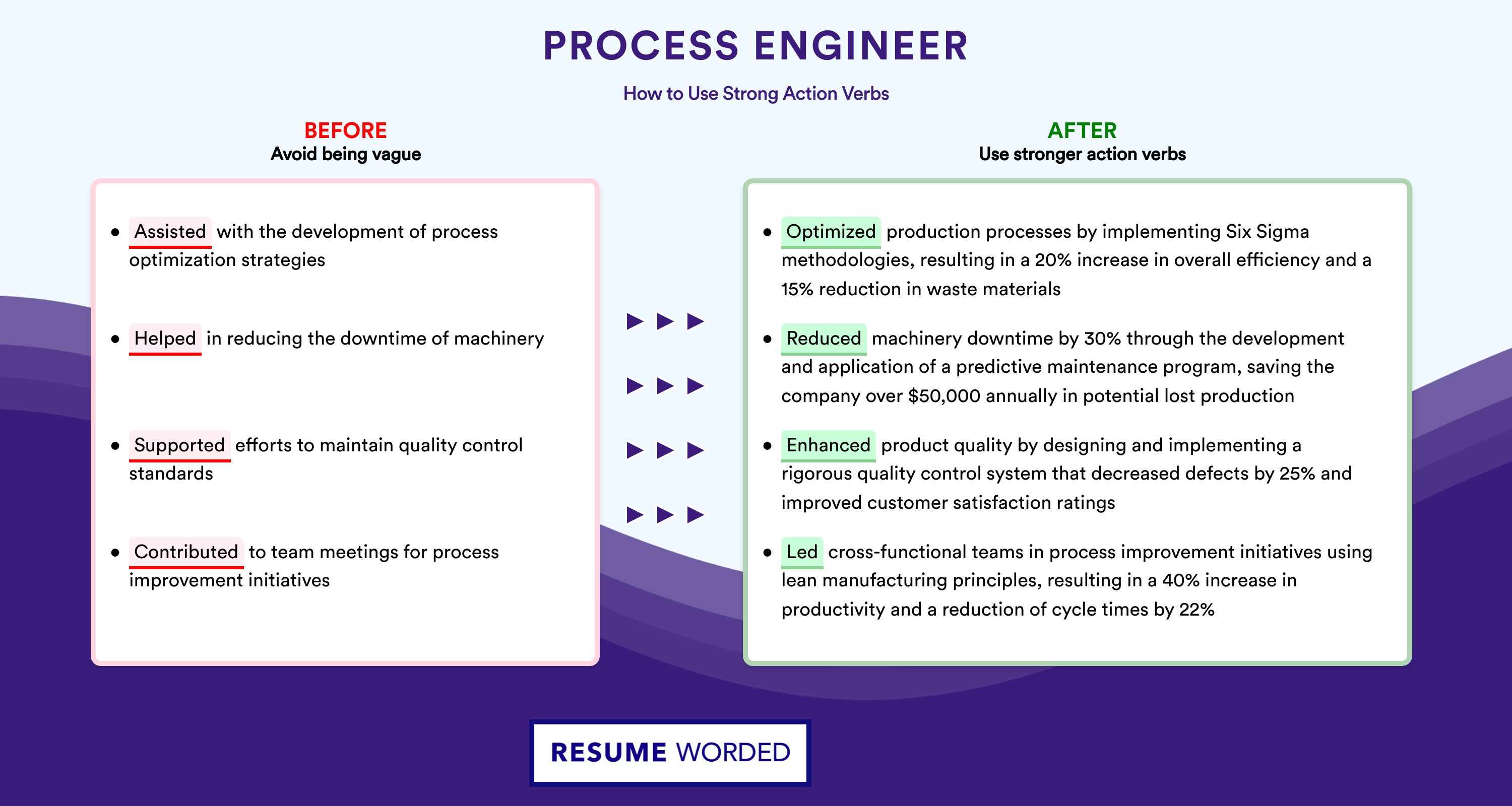

1. Use strong process engineering verbs

When describing your work experiences, start each bullet point with a strong action verb that demonstrates your process engineering skills:

- Designed and implemented a new inventory management system that reduced waste by 18%

- Analyzed production line performance and identified bottlenecks, increasing throughput by 11%

- Collaborated with cross-functional teams to launch 3 new product lines on time and 8% under budget

Avoid starting bullets with weak, vague verbs like "Helped with..." or "Responsible for...". Instead, use powerful verbs that convey your specific actions and results.

2. Quantify your impact with metrics

Numbers jump off the page and grab attention. Whenever possible, include specific metrics and data points that illustrate the impact of your work:

- Reduced scrap rate from 3.2% to 1.4% through root cause analysis and process optimization

- Increased production capacity by 150,000 units per year by designing new assembly layouts

- Delivered $3.5M in cost savings by negotiating new supplier contracts and optimizing inventory

If you don't have access to precise metrics, use numbers to provide a sense of scale:

- Managed a team of 12 engineers and technicians

- Oversaw the installation of 5 new packaging lines across 3 facilities

When estimating numbers, be conservative and use ranges if needed to maintain credibility. And always be prepared to discuss your results in an interview.

3. Showcase relevant tools and methodologies

As a process engineer, you likely use various tools, software, and methodologies in your work. Highlight your proficiency with the ones that are most relevant to your target role:

- Utilized Lean Six Sigma DMAIC methodology to identify and eliminate waste in the manufacturing process

- Designed process flow diagrams and value stream maps using Visio and AutoCAD

- Programmed PLCs using Ladder Logic to automate production equipment

Be specific about how you used each tool to achieve results. And don't list every tool you've ever used - focus on the ones that are most important for the job you want.

4. Highlight promotions and career growth

If you've been promoted or taken on increasing responsibility in your career, make that clear in your work experience section. This shows that you're a high performer and have been recognized by your employers.

Process Engineer, XYZ Corporation January 2018 - Present Senior Process Engineer July 2020 - Present • Led a team of 5 engineers to design and implement a new quality control system, reducing defects by 28% • Developed and delivered training on statistical process control to 50+ production staff Process Engineer January 2018 - June 2020 • Conducted process capability studies on key manufacturing processes, identifying opportunities for improvement • Collaborated with R&D to scale up new product introduction from pilot to full-scale production

If you have a strong career progression, consider a separate section for "Selected Promotions" to draw extra attention to your growth.

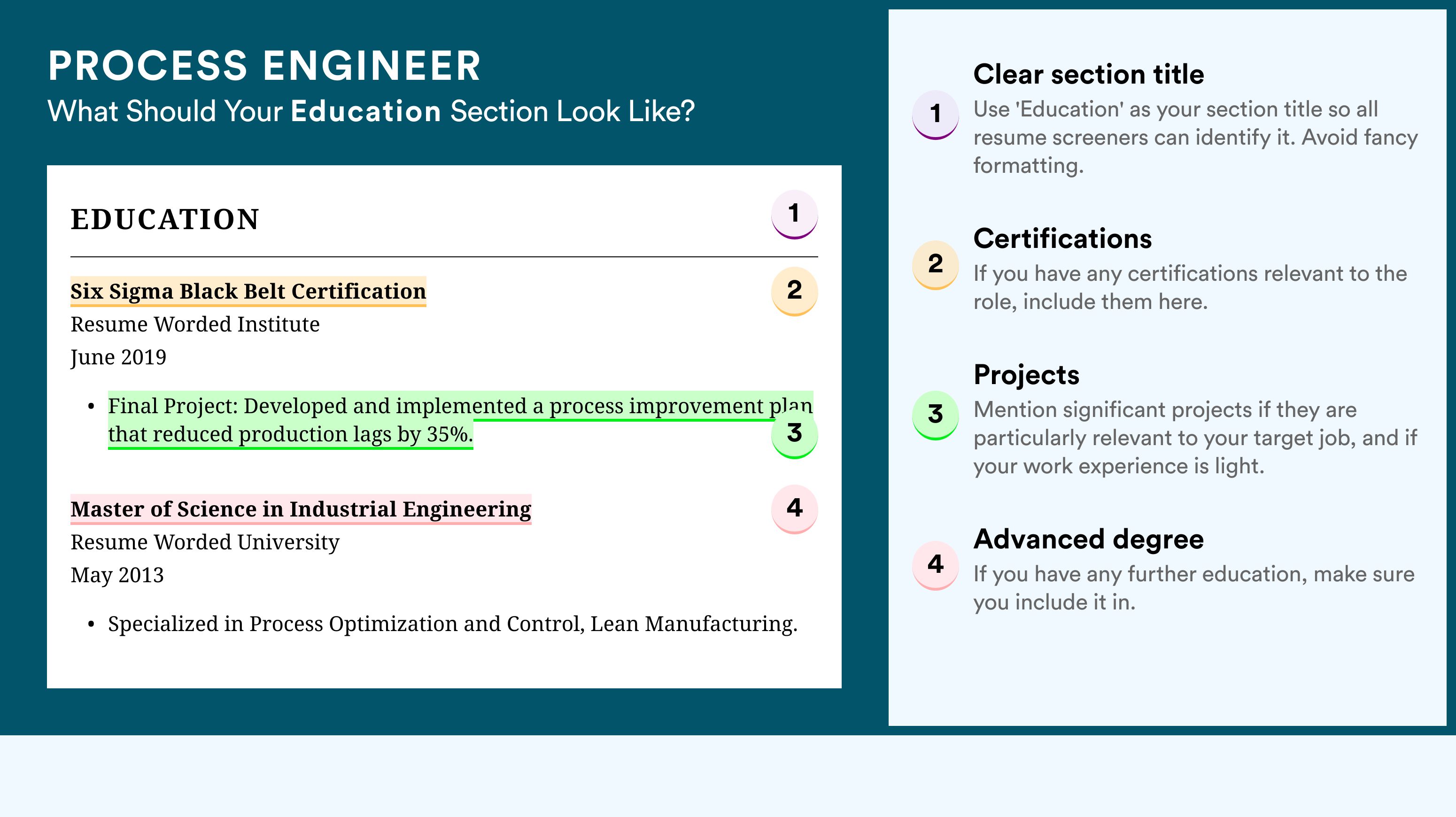

Education

Your education section is a key part of your process engineer resume. It shows hiring managers that you have the knowledge and training to excel in the role. In this section, we'll cover what to include and how to format your education section for maximum impact.

1. List your degrees in reverse chronological order

Start with your most recent degree first. For each degree, include:

- Name of the degree (e.g. Bachelor of Science in Chemical Engineering)

- Name of the university or college

- Graduation year

- Location (City, State)

Here's an example of how to list your education:

Master of Science in Industrial Engineering, 2020 Purdue University, West Lafayette, IN Bachelor of Science in Chemical Engineering, 2018 University of Texas at Austin, Austin, TX

2. Include relevant coursework and projects

If you're a recent graduate or have limited work experience, you can bolster your education section by listing relevant coursework, projects, or your thesis. This shows employers that you have hands-on experience with process engineering concepts.

Here's an example of what not to do:

- Relevant coursework: Fluid Mechanics, Thermodynamics, Process Design

Instead, provide more context and details:

- Relevant coursework: Advanced Process Design (developed PFDs and P&IDs for a multi-step chemical process), Fluid Mechanics (designed and built a working hydraulic pump system)

3. List important certifications and training

In addition to your degree(s), include any relevant certifications or specialized training you've completed. For process engineers, this could include:

- EIT/FE certification

- Six Sigma Green Belt or Black Belt

- PMP certification

- Industry-specific software training (e.g. AspenTech, Honeywell)

If you have several certifications, you may want to list them in a separate "Certifications" section on your resume. But if you only have one or two, you can include them in your education section.

4. Keep it concise if you're an experienced engineer

If you have several years of process engineering experience, your education section should be short and sweet. Hiring managers will be more interested in your work accomplishments than your degrees.

Here's an example of an education section for a senior-level process engineer:

M.S. Chemical Engineering, Stanford University B.S. Chemical Engineering, University of Michigan

Notice how the graduation years are omitted to avoid potential age discrimination. The degrees are also condensed into a single line to save space.

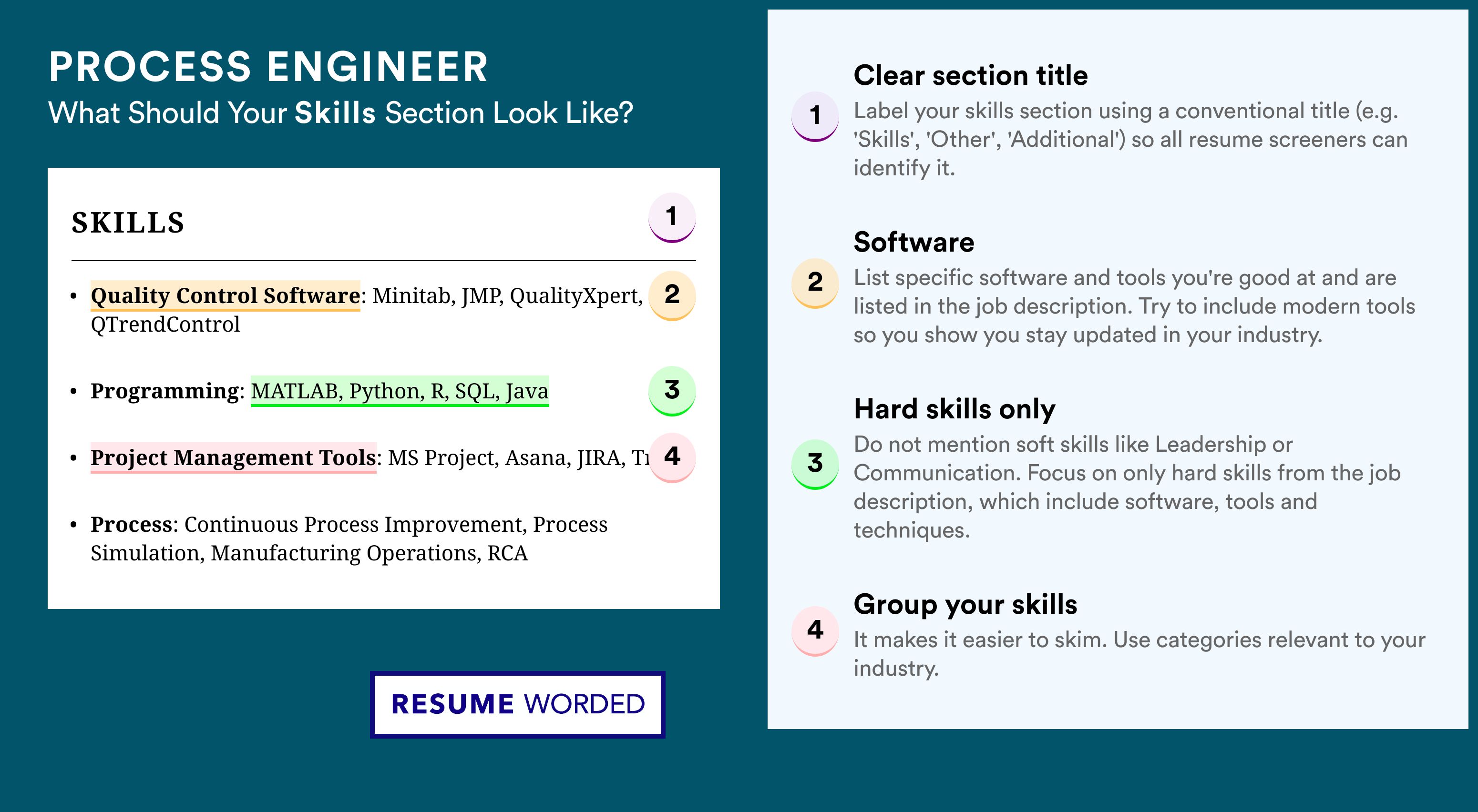

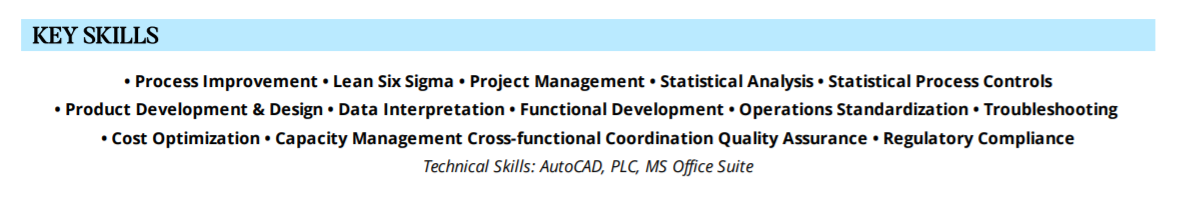

Skills

The skills section of your process engineer resume is critical in showcasing your technical abilities and expertise to potential employers. It's an opportunity to highlight the specific tools, techniques, and knowledge you possess that are relevant to the job you're applying for. In this section, we'll guide you through the key steps to crafting a compelling skills section that will catch the attention of hiring managers and help you stand out from the competition.

1. Tailor your skills to the job description

When creating your skills section, it's essential to align your skills with the requirements listed in the job description. Many companies use Applicant Tracking Systems (ATS) to screen resumes based on specific keywords and skills. To increase your chances of passing the ATS and landing an interview, carefully review the job posting and identify the key skills and qualifications the employer is looking for.

For example, if the job description emphasizes experience with lean manufacturing, Six Sigma, and process optimization, make sure to include these skills in your resume. However, avoid simply listing generic skills or buzzwords that don't demonstrate your actual expertise.

Skills: Process improvement, problem-solving, communication, teamwork

Skills: Lean manufacturing Six Sigma (Green Belt certified) Process optimization Statistical process control (SPC) Root cause analysis

2. Categorize your skills by relevance and expertise

Organizing your skills into categories can help make your skills section more readable and impactful. Group your skills based on their relevance to the job and your level of proficiency. This allows hiring managers to quickly assess your qualifications and expertise in key areas.

For example, you might create categories like:

- Manufacturing Processes : Lean manufacturing, Six Sigma, Kaizen, 5S, Value Stream Mapping

- Quality Management : Statistical process control (SPC), Design of Experiments (DOE), Failure Mode and Effects Analysis (FMEA), ISO 9001

- Software Skills : AutoCAD, Minitab, MS Visio, SAP

Within each category, list your skills in order of proficiency, starting with your strongest skills first. This helps emphasize your most valuable qualifications and makes it easier for hiring managers to identify your core competencies.

3. Quantify your skills with certifications and proficiency levels

To further strengthen your skills section, consider quantifying your expertise by including relevant certifications and proficiency levels. This provides concrete evidence of your qualifications and helps you stand out from other applicants.

For example, if you have a Six Sigma certification, specify the level (e.g., Green Belt, Black Belt) and the year you obtained it. Similarly, if you have experience with specific software or tools, indicate your proficiency level using terms like 'Advanced,' 'Intermediate,' or 'Proficient.'

Skills: Six Sigma Green Belt (certified 2019) Lean Manufacturing (Advanced) AutoCAD (Proficient) Minitab (Intermediate)

By quantifying your skills, you demonstrate a commitment to professional development and provide hiring managers with a clearer picture of your capabilities. This can help you differentiate yourself from candidates who simply list skills without any supporting evidence.

4. Highlight transferable skills for career transitions

If you are making a career transition into process engineering from a related field, it's essential to highlight transferable skills that demonstrate your ability to succeed in your new role. Look for skills and experiences from your previous positions that align with the requirements of a process engineer.

For example, if you have a background in quality assurance, you might emphasize your experience with statistical analysis, problem-solving, and continuous improvement initiatives. Similarly, if you have worked in a manufacturing environment, you could highlight your knowledge of production processes, safety procedures, and lean principles.

Skills: Quality assurance Statistical analysis Problem-solving Continuous improvement Manufacturing processes Safety procedures Lean principles

By showcasing your transferable skills, you demonstrate your potential to adapt to a new role and contribute to the success of the organization, even if you don't have direct experience as a process engineer.

Skills For Process Engineer Resumes

Here are examples of popular skills from Process Engineer job descriptions that you can include on your resume.

- Continuous Improvement

- Requirements Gathering

- Business Process Improvement

- Agile Methodologies

- Root Cause Analysis

- Lean Six Sigma

Skills Word Cloud For Process Engineer Resumes

This word cloud highlights the important keywords that appear on Process Engineer job descriptions and resumes. The bigger the word, the more frequently it appears on job postings, and the more likely you should include it in your resume.

How to use these skills?

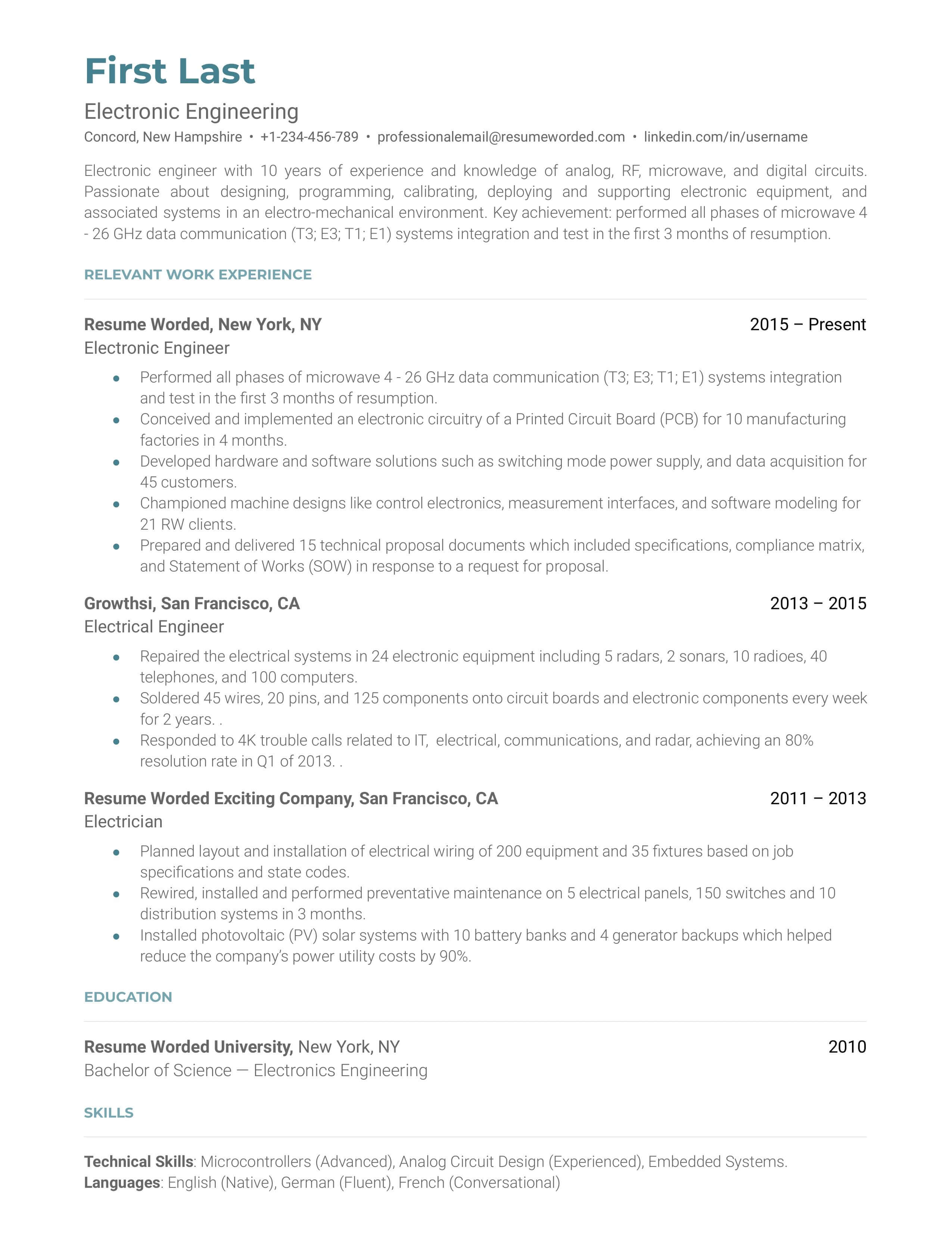

Similar resume templates, electronic technician.

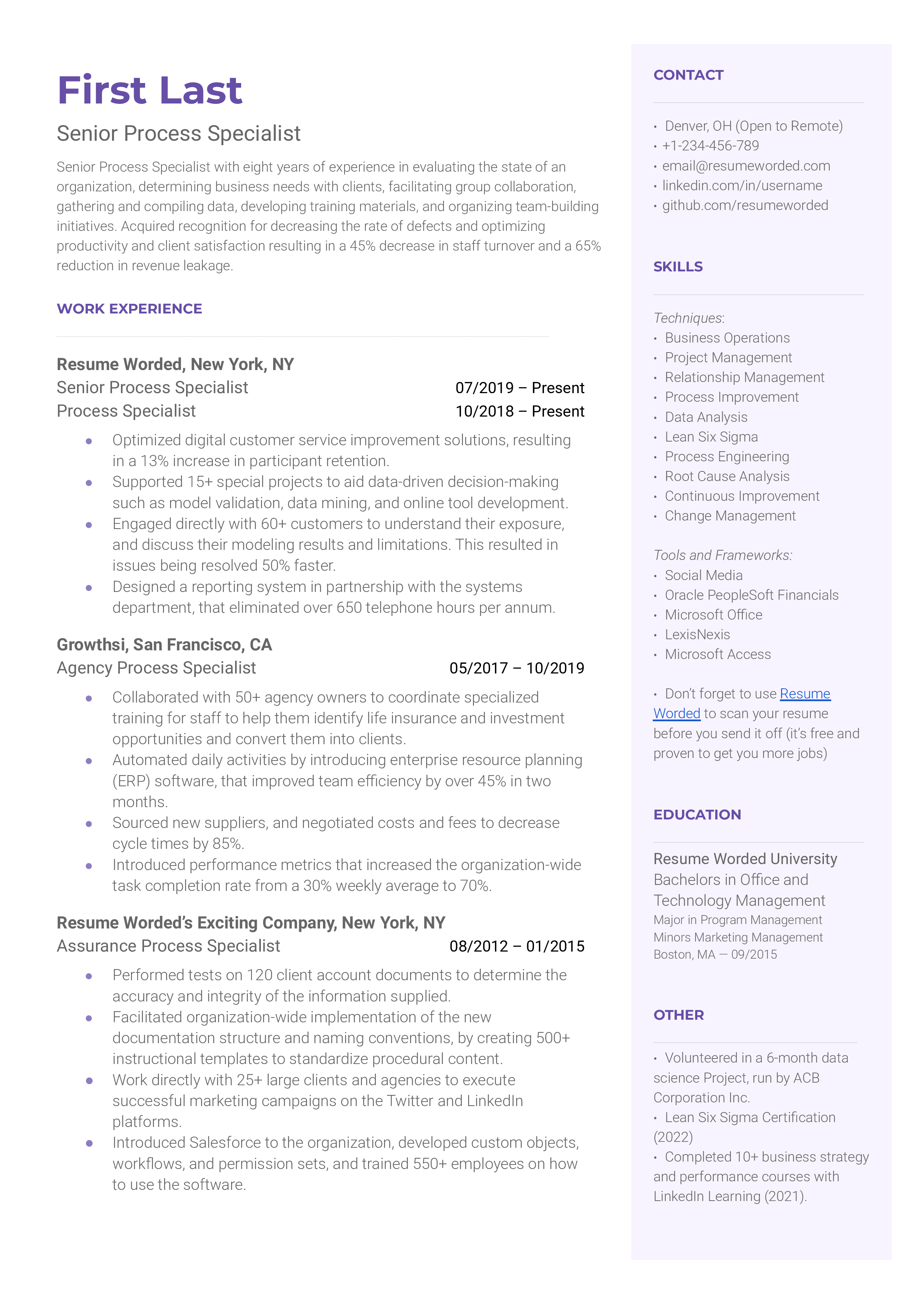

Process Specialist

Site Manager

- Network Engineer Resume Guide

- Environmental Engineer Resume Guide

- Software Tester Resume Guide

- Technology Director Resume Guide

- Director of Engineering Resume Guide

Resume Guide: Detailed Insights From Recruiters

- Project Engineer Resume Guide & Examples for 2022

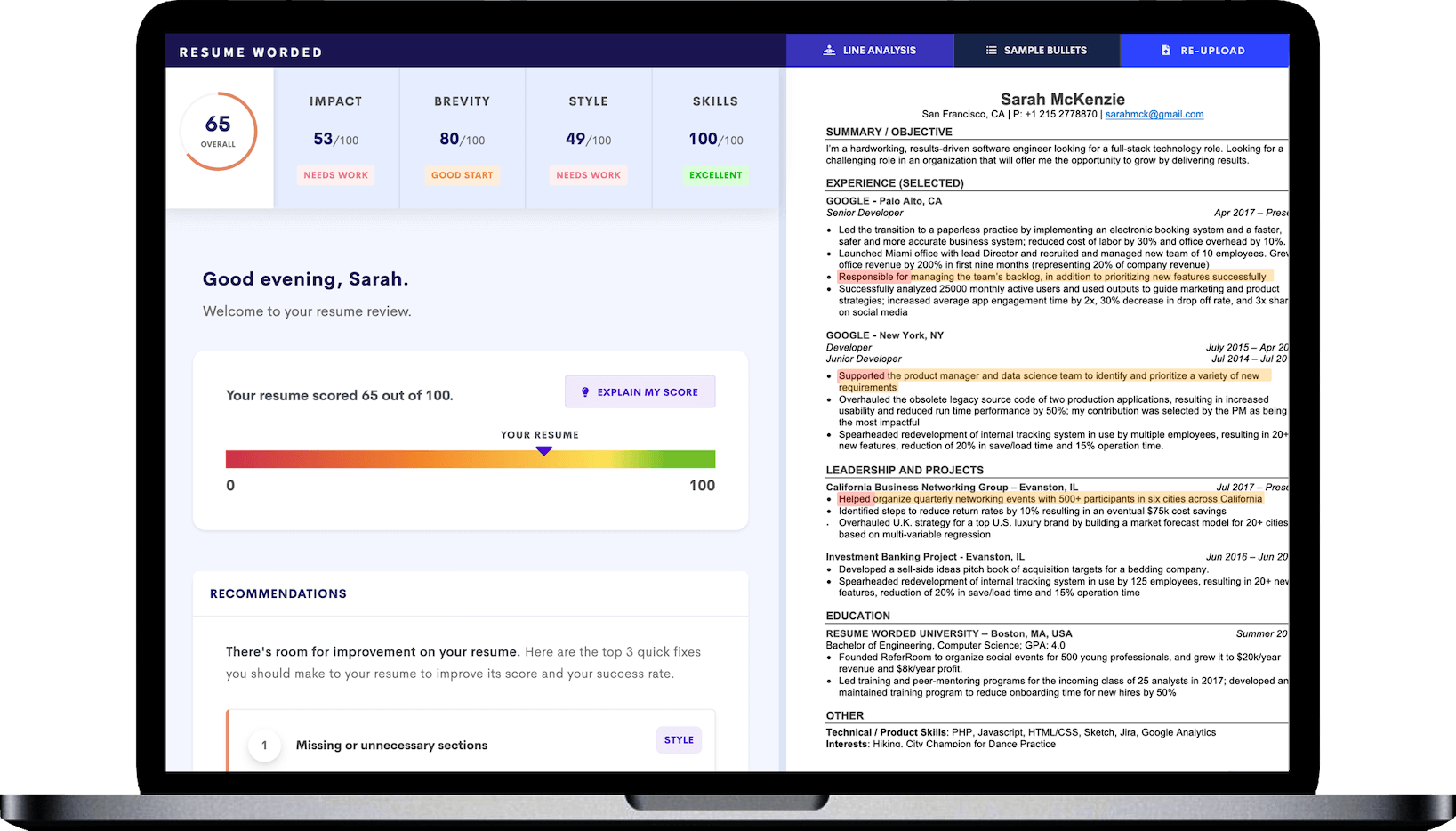

Improve your Process Engineer resume, instantly.

Use our free resume checker to get expert feedback on your resume. You will:

• Get a resume score compared to other Process Engineer resumes in your industry.

• Fix all your resume's mistakes.

• Find the Process Engineer skills your resume is missing.

• Get rid of hidden red flags the hiring managers and resume screeners look for.

It's instant, free and trusted by 1+ million job seekers globally. Get a better resume, guaranteed .

Process Engineer Resumes

- Template #1: Process Engineer

- Template #2: Process Engineer

- Template #3: Process Engineer

- Template #4: Manufacturing Process Engineer

- Template #5: Chemical Process Engineer

- Skills for Process Engineer Resumes

- Free Process Engineer Resume Review

- Other Engineering Resumes

- Process Engineer Interview Guide

- Process Engineer Sample Cover Letters

- Alternative Careers to a Process Engineer

- All Resumes

- Resume Action Verbs

Download this PDF template.

Creating an account is free and takes five seconds. you'll get access to the pdf version of this resume template., choose an option..

- Have an account? Sign in

E-mail Please enter a valid email address This email address hasn't been signed up yet, or it has already been signed up with Facebook or Google login.

Password Show Your password needs to be between 6 and 50 characters long, and must contain at least 1 letter and 1 number. It looks like your password is incorrect.

Remember me

Forgot your password?

Sign up to get access to Resume Worded's Career Coaching platform in less than 2 minutes

Name Please enter your name correctly

E-mail Remember to use a real email address that you have access to. You will need to confirm your email address before you get access to our features, so please enter it correctly. Please enter a valid email address, or another email address to sign up. We unfortunately can't accept that email domain right now. This email address has already been taken, or you've already signed up via Google or Facebook login. We currently are experiencing a very high server load so Email signup is currently disabled for the next 24 hours. Please sign up with Google or Facebook to continue! We apologize for the inconvenience!

Password Show Your password needs to be between 6 and 50 characters long, and must contain at least 1 letter and 1 number.

Receive resume templates, real resume samples, and updates monthly via email

By continuing, you agree to our Terms and Conditions and Privacy Policy .

Lost your password? Please enter the email address you used when you signed up. We'll send you a link to create a new password.

E-mail This email address either hasn't been signed up yet, or you signed up with Facebook or Google. This email address doesn't look valid.

Back to log-in

These professional templates are optimized to beat resume screeners (i.e. the Applicant Tracking System). You can download the templates in Word, Google Docs, or PDF. For free (limited time).

access samples from top resumes, get inspired by real bullet points that helped candidates get into top companies., get a resume score., find out how effective your resume really is. you'll get access to our confidential resume review tool which will tell you how recruiters see your resume..

Writing an effective resume has never been easier .

Upgrade to resume worded pro to unlock your full resume review., get this resume template (+ 6 others), plus proven bullet points., for a small one-time fee, you'll get everything you need to write a winning resume in your industry., here's what you'll get:.

- 📄 Get the editable resume template in Google Docs + Word . Plus, you'll also get all 6 other templates .

- ✍️ Get sample bullet points that worked for others in your industry . Copy proven lines and tailor them to your resume.

- 🎯 Optimized to pass all resume screeners (i.e. ATS) . All templates have been professionally designed by recruiters and 100% readable by ATS.

Buy now. Instant delivery via email.

instant access. one-time only., what's your email address.

I had a clear uptick in responses after using your template. I got many compliments on it from senior hiring staff, and my resume scored way higher when I ran it through ATS resume scanners because it was more readable. Thank you!

Thank you for the checklist! I realized I was making so many mistakes on my resume that I've now fixed. I'm much more confident in my resume now.

- Resume Builder

- Resume Templates

- Resume Formats

- Resume Examples

- Cover Letter Builder

- Cover Letter Templates

- Cover Letter Formats

- Cover Letter Examples

- Career Advice

- Interview Questions

- Resume Skills

- Resume Objectives

- Job Description

- Job Responsibilities

- FAQ’s

Process Engineer Resume Examples

Writing a resume for a process engineer role requires a specific set of skills and industry know-how. In this blog post, we will discuss how to craft a stunning process engineer resume from scratch. We’ll provide resume tips and examples to give you an idea of what a professional resume looks like and how to highlight your relevant experience and accomplishments. Whether you’re a recent college grad or a seasoned process engineer, this blog post will provide helpful information to get your resume in tip-top shape.

If you didn’t find what you were looking for, be sure to check out our complete library of resume examples .

Start building your dream career today!

Create your professional resume in just 5 minutes with our easy-to-use resume builder!

Process Engineer

123 Main Street | Anytown, USA 99999 | Phone: (123) 456-7890 | Email: [email protected]

Highly accomplished and results- oriented process engineer with 8+ years of experience in the field. Adept at developing innovative solutions to complex problems to optimize processes and improve system performance. Proven record of success in leading process improvement initiatives, utilizing advanced process engineering strategies and technologies, and leveraging the latest industry best practices. Skilled in developing comprehensive technical reports and utilizing data- driven analysis to identify opportunities.

Core Skills :

- Process Improvement

- Process Optimization

- Technical Troubleshooting

- Analytical Problem Solving

- Data- Driven Analysis

- Advanced Process Engineering Strategies

- Technical Report Writing

- Project Management

- Quality Assurance

- Safety Compliance

Professional Experience :

Process Engineer, ABC Company, August 2012 – Present

- Analyze, design, develop and validate process designs to improve current processes and reduce downtime

- Lead process improvement initiatives utilizing advanced process engineering strategies and technologies

- Use data- driven analysis to identify opportunities for process optimization

- Draft comprehensive technical reports on process designs and improvements

- Utilize quality assurance best practices to ensure product safety and reliability

- Monitor process efficiency and performance, and analyze deviations

Process Engineer, XYZ Corporation, March 2009 – August 2012

- Developed innovative solutions to complex problems to optimize processes

- Oversaw process engineering initiatives and ensured compliance with safety regulations

- Managed project schedules and budgets, and monitored progress of assigned projects

- Evaluated current processes and identified areas for process improvement

- Prepared detailed documentation for process designs, including technical reports

- Collaborated with cross- functional teams to ensure timely completion of projects

Education :

Bachelor of Science in Process Engineering, XYZ University, 2008 Master of Science in Process Engineering, ABC University, 2010

Create My Resume

Build a professional resume in just minutes for free.

Process Engineer Resume with No Experience

- Recent university graduate with a degree in Chemical Engineering.

- Highly motivated and eager to contribute to a successful organization.

- Able to work in a team setting and prioritize tasks to meet organizational goals and objectives.

- Strong understanding of chemical engineering processes and principles.

- Able to identify and analyze process problems and use innovative approaches to solve them.

- Knowledge of safety regulations and quality control processes.

- Proficient in MS Office applications including Word, Excel, and PowerPoint.

Responsibilities

- Develop and implement process improvements to meet production goals.

- Monitor and analyze process performance to identify areas of improvement.

- Conduct research to develop new processes and identify areas for cost savings.

- Develop technical documents for process control and operations.

- Ensure compliance with safety regulations and quality control standards.

Experience 0 Years

Level Junior

Education Bachelor’s

Process Engineer Resume with 2 Years of Experience

A highly motivated and results- driven Process Engineer with 2 years of experience in chemical plant operations. Adept at developing and implementing process improvement tools to optimize plant performance and safety. Possesses a keen eye for identifying areas for cost efficiency and a strong passion for continuous improvement. Highly organized and detail- oriented with strong analytical and problem- solving skills.

- Plant Operations

- Risk Analysis

- Cost Efficiency

- Quality Control

- Regulatory Compliance

- Process Modelling

- Data Analysis

Responsibilities :

- Develop and implement process improvement tools to optimize plant performance and safety.

- Monitor data and analyze the process performance to identify areas for improvement.

- Design and implement cost efficiency projects for process optimization.

- Prepare and review documents for process compliance and quality control.

- Collaborate with various stakeholders to gather requirements and develop process models.

- Responsible for developing and executing process improvement initiatives.

- Coordinate with various teams to ensure operational efficiency.

- Monitor and analyze process data to identify anomalies and take corrective action.

- Ensure regulatory compliance with all relevant safety standards.

Experience 2+ Years

Process Engineer Resume with 5 Years of Experience

Dynamic and highly organized Process Engineer with 5+ years of experience in designing and managing the development of innovative and efficient processes. Excellent coordination, communication, and problem- solving skills. Adept at utilizing data and analytics to optimize production, implement cost- savings, and develop efficient processes. Expert in projects management and optimizing production operations to ensure quality standards and client satisfaction.

- Process Design

- Data Analytics

- Troubleshooting

- Cost Analysis

- Developed and managed processes for continuous improvement to production operations.

- Simulated process design, effectively reducing cost and time- to- market.

- Analyzed data and generated reports to monitor process performance.

- Led team of engineers and technicians to troubleshoot and resolve technical issues.

- Developed quality assurance processes to ensure compliance with standards and client expectations.

- Implemented cost- saving measures and process optimization initiatives.

- Established safety protocols and ensured compliance.

- Monitored and adjusted process production to meet customer requirements.

Experience 5+ Years

Level Senior

Process Engineer Resume with 7 Years of Experience

A Process Engineer with seven years of experience in the industrial engineering field. I have an extensive background in designing, installing, and commissioning plant systems and equipment; researching, evaluating, and developing processes; and managing high- volume production operations. My technical proficiencies include knowledge of a wide range of engineering tools, systems, and concepts as well as experience using CAD/CAM software systems. I am committed to product safety and quality control, as well as efficient plant operations.

- Process engineering

- CAD/CAM software systems

- Plant design

- Equipment installation and commissioning

- Research and development

- Quality control and safety

- Project management

- High- volume production operations

- Designed, installed, and commissioned plant systems and equipment

- Developed new processes and equipment to improve quality and reduce costs

- Managed high- volume production operations

- Researched and evaluated new technologies and approaches to improve efficiency

- Ensured product safety and quality control through adherence to government regulations and industry standards

- Utilized a wide range of engineering tools, systems, and concepts

- Trained and supervised staff in the proper use of process engineering tools, systems, and concepts

- Worked collaboratively with other departments to ensure a smooth workflow and successful project completion

Experience 7+ Years

Process Engineer Resume with 10 Years of Experience

Seasoned process engineer with 10 years of experience in production, process control, and troubleshooting. Skilled problem solver, with a deep understanding of process engineering principles and methodology. Adept in the use of process engineering software tools and engineering instrumentation. Experienced in developing and optimizing processes to improve efficiency and cost- effectiveness.

- Process engineering principles

- Process optimization

- Process control

- Process engineering software

- Instrumentation

- Responsible for the design, development, and implementation of process engineering projects.

- Optimized processes to reduce cost and improve efficiency.

- Developed process engineering plans and specifications for new processes.

- Monitored and controlled process operations using various instrumentation.

- Troubleshot process- related issues, identified root causes and suggested corrective actions.

- Assisted in the preparation of safety documents and technical reports.

- Collaborated with production personnel to ensure process operations meet safety and quality standards.

Experience 10+ Years

Level Senior Manager

Education Master’s

Process Engineer Resume with 15 Years of Experience

An experienced Process Engineer with 15 years of experience and a track record of successful project work in the chemical engineering, oil and gas, and manufacturing industries. I have a proven ability to design and implement process control strategies, optimize operations, troubleshoot and develop innovative solutions to process- related problems. I possess strong communication, leadership, and data analysis skills, and am motivated to improve operations and processes through cost- effective and safety- focused strategies.

- Proven Ability to Design and Implement Process Control Strategies

- Demonstrated Ability to Troubleshoot and Develop Innovative Solutions

- Strong Communication, Leadership, and Data Analysis Skills

- Experienced in Chemical Engineering, Oil, and Gas Manufacturing

- Ability to Implement Cost- Effective and Safety- Focused Strategies

- Design and implement process control strategies for chemical engineering and oil and gas related operations.

- Troubleshoot process- related problems and develop innovative solutions.

- Develop cost- effective and safety- focused strategies for process improvement.

- Monitor and adjust process systems to ensure quality and efficiency.

- Prepare process reports, documenting actions taken and results achieved.

- Lead and coordinate teams of process engineering personnel.

- Interpret and analyze data gathered from process operations.

- Investigate and implement new technologies to optimize operational efficiency.

Experience 15+ Years

Level Director

In addition to this, be sure to check out our resume templates , resume formats , cover letter examples , job description , and career advice pages for more helpful tips and advice.

What should be included in a Process Engineer resume?

The process engineer is an integral part of a company’s operations and is responsible for designing, creating, and improving the production process. It is important to have a well-crafted resume that showcases your skills and experience as a process engineer. Here are some items that should be included in a process engineer resume:

- Professional Summary: A brief overview of your professional experience and qualifications as a process engineer.

- Technical Skills: List your technical abilities such as experience with software, systems, and machinery related to process engineering.

- Education: Include the educational institutions you have attended, the degrees you have achieved, and any certifications you have earned.

- Work Experience: Describe your past roles as a process engineer, highlighting any successful projects or initiatives you have worked on.

- Problem Solving & Troubleshooting: Describe your problem-solving abilities and any experience you have resolving technical issues in a process engineering environment.

- Leadership & Teamwork: Describe any leadership or team-management experience you have in a process engineering environment.

- Communication Skills: Describe your ability to communicate with other staff, clients, and vendors.

- Professional Development: List any professional development activities you have completed, such as attending conferences or workshops.

By including these elements in your process engineer resume, you can showcase your skills and experience in a professional and effective way.

What is a good summary for a Process Engineer resume?

A Process Engineer resume should highlight a candidate’s experience in the engineering and facility management field. It should include relevant qualifications, such as a Bachelor’s degree in engineering or equivalent experience, as well as any relevant certifications. The resume should also focus on the candidate’s experience in process engineering, including the design, implementation and maintenance of processes, equipment and systems. It should also emphasize their knowledge of engineering principles, such as safety, environmental regulations, scheduling and budgeting. Finally, the resume should feature any special skills or experience relevant to the role, such as CAD software expertise, problem-solving and process optimization.

What is a good objective for a Process Engineer resume?

Process Engineer resumes should convey the candidate’s abilities in design, implementation, and optimization of production process, as well as the ability to reduce costs and improve quality. An effective job objective should be tailored to the specific role and company.

A good objective for a Process Engineer resume might include:

- Seeking a Process Engineer position with ABC Company, utilizing my experience in improving process efficiency and product quality.

- Looking to apply my extensive knowledge in process engineering and optimization in a Process Engineer role with XYZ Corporation.

- Passionate Process Engineer seeking a position to help drive operational excellence through the development of innovative processes.

- Experienced Process Engineer interested in a position with an organization that values the improvement of production processes and product quality.

How do you list Process Engineer skills on a resume?

Writing a resume is hard – you need to make sure that you can showcase both your experience and your skills in the most effective way. For process engineers, this can be especially tricky as you have a range of skills that may be relevant for a prospective employer.

Here are some of the skills you should list on your resume that will demonstrate the value you bring to any employer:

- Expert knowledge of process engineering principles, techniques and methodologies

- Ability to develop, design and implement process engineering solutions

- Skilled in process optimization and improvement

- Experienced in process modelling and simulation

- Extensive experience with process safety and risk assessments

- Familiarity with industry and regulatory standards

- Proficiency in data analysis and interpreting data

- Ability to identify and solve complex engineering problems

- Outstanding analytical, problem solving, and organizational skills

- Strong interpersonal and communication skills

- Proficient in CAD/CAE tools and software packages

What skills should I put on my resume for Process Engineer?

Process engineers are responsible for developing, implementing, and optimizing industrial production processes. When crafting your resume, it’s important to include relevant skills that make you stand out as a qualified candidate. Here are some of the skills you should consider including on your resume for a process engineering job:

- Technical Proficiency: Process engineers are expected to have a strong technical background with a deep understanding of process engineering principles, practices, and principles of design. Demonstrate your technical proficiency with your knowledge of production processes, computer programming, and software engineering.

- Problem-solving Skills: Process engineers must be able to identify areas of improvement and develop solutions to improve production processes. In your resume, highlight your ability to troubleshoot, analyze, and solve complex technical problems.

- Project Management: Process engineers must be able to manage multiple projects at once. Be sure to include your ability to set project goals, manage timelines, and delegate tasks.

- Communication: Process engineers must be able to communicate effectively with other engineers, management, and production personnel. Demonstrate your ability to communicate clearly in both written and verbal form on your resume.

- Leadership: Process engineers must have the skills to inspire and lead other engineers. Demonstrate your leadership skills on your resume by highlighting your ability to motivate and mentor teams.

By including these skills, you will demonstrate that you are a qualified and capable process engineer. When crafting your resume, be sure to tailor your skills to the job description to ensure you’re the best fit for the position.

Key takeaways for an Process Engineer resume

As a process engineer, your resume needs to make a strong impression on potential employers. Here are some key takeaways you should consider when composing your resume:

- Include your relevant qualifications: Make sure to outline your qualifications such as any certifications or licenses you hold, as well as any relevant experience you may have in the field. This will help employers understand that you have the technical expertise to excel in the position.

- Highlight any achievements: Showcase any awards or achievements you have earned during your career as a process engineer. This may include successes in streamlining processes, improving efficiency, or reducing costs. These accomplishments will demonstrate your value to potential employers.

- Detail your knowledge of the industry: Show employers that you have a deep understanding of the process engineering industry. Detail the types of processes you have worked on, the software and equipment you are experienced in using, and any specialized knowledge you possess.

- Showcase your communication skills: As a process engineer, you will need to be able to communicate effectively with other team members, clients, and managers. Show employers that you have strong communication abilities by emphasizing any past experiences where you effectively collaborated with others.

By following these tips, you can create a strong resume that will make a lasting impression on potential employers. Good luck!

Let us help you build your Resume!

Make your resume more organized and attractive with our Resume Builder

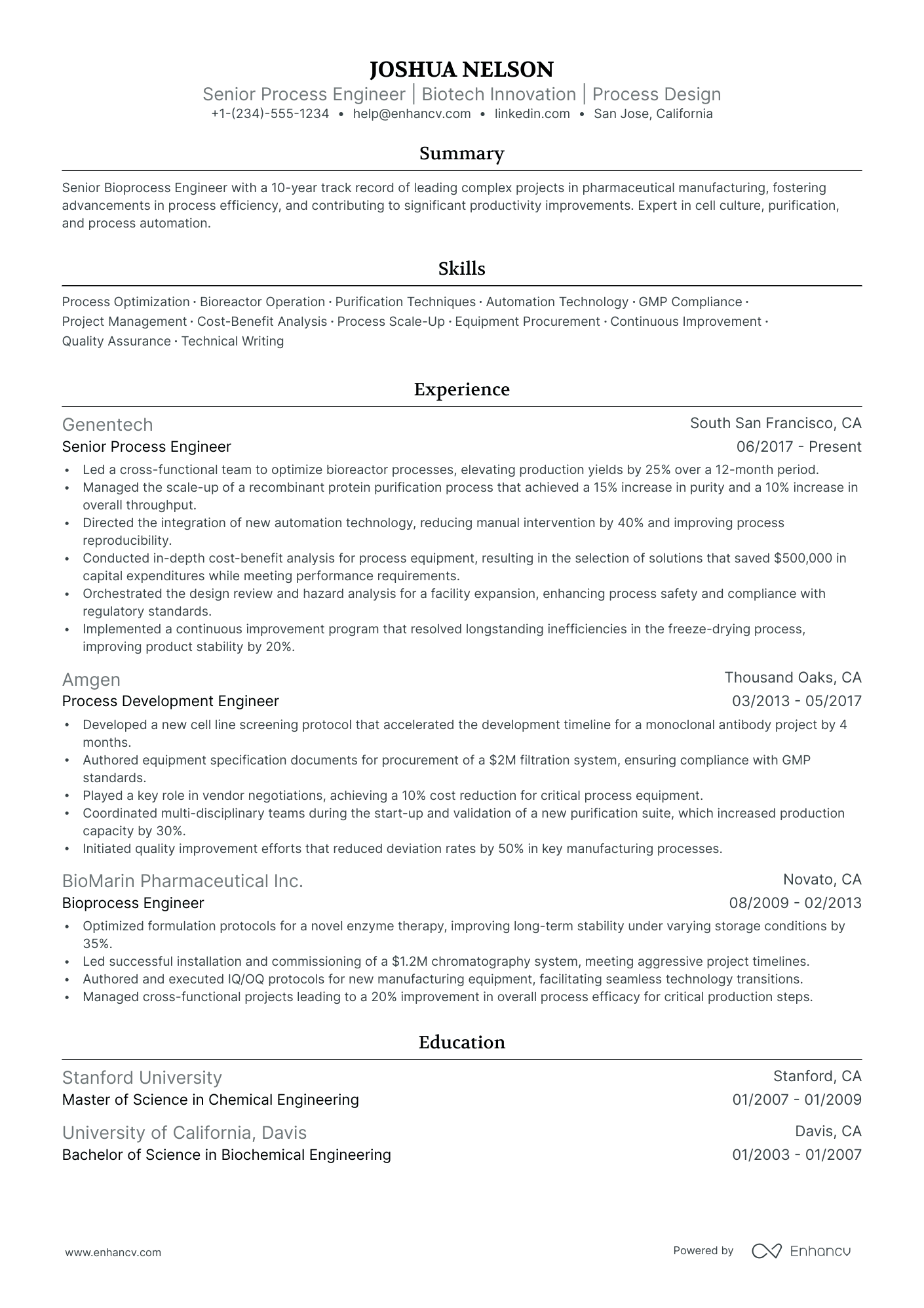

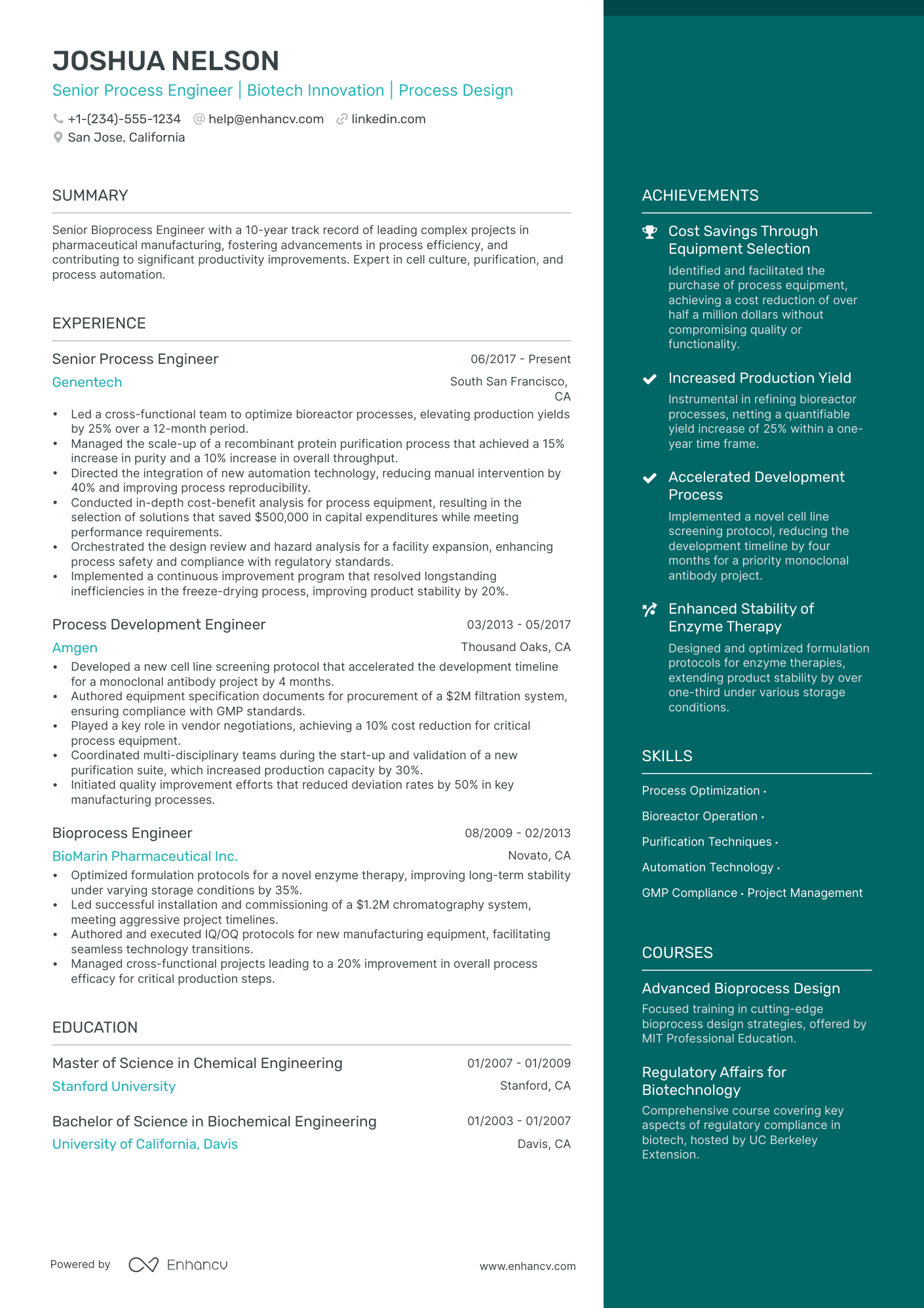

- • Led a cross-functional team to optimize bioreactor processes, elevating production yields by 25% over a 12-month period.

- • Managed the scale-up of a recombinant protein purification process that achieved a 15% increase in purity and a 10% increase in overall throughput.

- • Directed the integration of new automation technology, reducing manual intervention by 40% and improving process reproducibility.

- • Conducted in-depth cost-benefit analysis for process equipment, resulting in the selection of solutions that saved $500,000 in capital expenditures while meeting performance requirements.

- • Orchestrated the design review and hazard analysis for a facility expansion, enhancing process safety and compliance with regulatory standards.

- • Implemented a continuous improvement program that resolved longstanding inefficiencies in the freeze-drying process, improving product stability by 20%.

- • Developed a new cell line screening protocol that accelerated the development timeline for a monoclonal antibody project by 4 months.

- • Authored equipment specification documents for procurement of a $2M filtration system, ensuring compliance with GMP standards.

- • Played a key role in vendor negotiations, achieving a 10% cost reduction for critical process equipment.

- • Coordinated multi-disciplinary teams during the start-up and validation of a new purification suite, which increased production capacity by 30%.

- • Initiated quality improvement efforts that reduced deviation rates by 50% in key manufacturing processes.

- • Optimized formulation protocols for a novel enzyme therapy, improving long-term stability under varying storage conditions by 35%.

- • Led successful installation and commissioning of a $1.2M chromatography system, meeting aggressive project timelines.

- • Authored and executed IQ/OQ protocols for new manufacturing equipment, facilitating seamless technology transitions.

- • Managed cross-functional projects leading to a 20% improvement in overall process efficacy for critical production steps.

5 Process Engineer Resume Examples & Guide for 2024

On your process engineer resume, highlight your analytical skills. Demonstrate how your technical proficiency has optimized operations. Showcase your project management experience. Employers want to see your ability to lead and execute process improvements effectively.

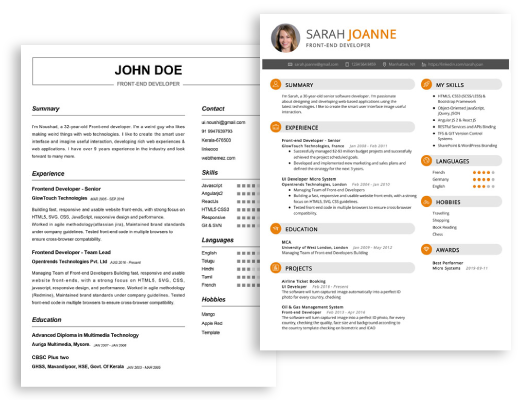

All resume examples in this guide

Traditional

Resume Guide

Resume Format Tips

Resume Experience

Skills on Resume

Education & Certifications

Resume Summary Tips

Additional Resume Sections

Key Takeaways

As a process engineer, articulating the complexity of your projects without overwhelming your potential employer can be a daunting resume challenge. Our guide provides clear strategies to concisely convey the impact of your technical expertise, ensuring that your key achievements stand out while maintaining readability.

- Defining the highlights of your process engineer career through your resume summary, objective, and experience.

- Real-world process engineer resume samples with best practices on how to stand out amongst the endless pile of candidate resumes.

- Most in-demand process engineer resume skills and certifications across the industry.

- Standardizing your resume layout, while maintaining your creativity and individuality.

If the process engineer resume isn't the right one for you, take a look at other related guides we have:

- Marketing Product Manager Resume Example

- Clinical Project Manager Resume Example

- Principal Product Manager Resume Example

- Digital Product Manager Resume Example

- Public Health Program Manager Resume Example

- Education Program Manager Resume Example

- Mental Health Program Manager Resume Example

- Nonprofit Program Manager Resume Example

- Digital Project Manager Resume Example

- Product Development Manager Resume Example

Optimize your process engineer resume format to pass the recruiters' assessment

What recruiters are looking for is systematised content that is clear and coherent. Thus, your process engineer resume needs to answer requirements and why you're the best candidate for the role from the get-go.

- Sorting your experience in the reverse chronological order - starting with your most recent and relevant roles. This is an excellent choice for more experienced professionals;

- Writing your contact information (e.g. personal phone number and email address ) and your portfolio or LinkedIn link in your process engineer resume header. If you're wondering to include a photo or not, always make sure that it's appropriate for the country you're applying in;

- Use the basic, most important process engineer resume sections - your experience, education, summary, etc. Use your resume's real estate wisely to tell a compelling, professional story and match job description's keywords;

- Don't go overboard with the length of your resume. One page is absolutely fine if you happen to have under a decade of relevant experience.

Are you still wondering if you should submit your process engineer resume in PDF or Word format ? The PDF has a few more advantages, as it doesn't change the format and the text can't be altered upon application.

Format matters most when your process engineer resume is assessed by the Applicant Tracker System (or the ATS).

The ATS parses resumes, looking for specific keywords, skills or experience that match the job description.

P.S. We recently did a study on how the ATS works and were able to demystify three of the biggest misconceptions about how it assesses candidate resumes.

To pass the ATS evaluation, select any of the serif or sans-serif fonts. Popular choices that would help your process engineer resume stand out include Raleway, Exo 2, Montserrat, etc.

Most traditionalists go for Arial or Times New Roman, but it's often the case that many candidates choose these fonts, and you'd thus lose points on the uniqueness front.

Upload & Check Your Resume

Drop your resume here or choose a file . PDF & DOCX only. Max 2MB file size.

Showcase any ongoing or recent educational efforts to stay updated in your field.

The five (plus) definite sections your resume for a process engineer job should include are:

- Header with your headline, contact details, and/or a preview of your work

- Summary (or objective) to pinpoint how your success aligns with the role

- Experience with bullets of your most relevant achievements in the field

- Skills to integrate vital job requirements (both technical and personal)

- Your further dedication to the field, showcased via relevant higher education and/or certifications

What recruiters want to see on your resume:

- Demonstrated experience in process design, optimization, and scale-up

- Proficiency in process simulation and modeling tools (e.g., HYSYS, Aspen Plus)

- Understanding of P&ID development and knowledge of process control strategies

- Experience with continuous improvement methodologies (e.g., Six Sigma, Lean Manufacturing)

- Knowledge of relevant industry standards and regulations (e.g., OSHA, EPA, ISO)

Guide to your most impressive process engineer resume experience section

When it comes to your resume experience , stick to these simple, yet effective five steps:

- Show how your experience is relevant by including your responsibility, skill used, and outcome/-s;

- Use individual bullets to answer how your experience aligns with the job requirements;

- Think of a way to demonstrate the tangible results of your success with stats, numbers, and/or percentages ;

- Always tailor the experience section to the process engineer role you're applying for - this may sometimes include taking out irrelevant experience items;

- Highlight your best (and most relevant) achievements towards the top of each experience bullet.

You're not alone if you're struggling with curating your experience section. That's why we've prepared some professional, real-life process engineer resume samples to show how to best write your experience section (and more).

- Led the optimization project for the ammonia synthesis loop, enhancing conversion rates by 17% through meticulous catalyst performance evaluation.

- Implemented advanced process control strategies that reduced energy consumption by 10%, translating to annual savings of $200K for the plant operations.

- Orchestrated the successful scale-up of a new biochemical route from pilot to full-scale production, maintaining a 99% product quality consistency.

- Designed and executed experiments that led to a 25% increase in yield for a key pharmaceutical compound, significantly contributing to a boost in product margin.

- Streamlined cross-functional team efforts in the development of a new waste-water treatment process, achieving regulatory compliance 6 months ahead of schedule.

- Developed a company-wide training program on process safety management techniques, reducing safety incidents by 30% over a 2-year period.

- Coordinated with multi-disciplinary teams to troubleshoot and resolve a critical reactor bottleneck, enhancing overall plant throughput by 15%.

- Successfully managed a project to integrate a solvent recovery system into the existing production line, reclaiming 95% of solvents used and dramatically reducing environmental impact.

- Championed the application of Six Sigma methodologies to improve the efficiency of the packaging line, which decreased material waste by 40%.

- Implemented a real-time monitoring system for process parameters, which allowed for proactive adjustments and resulted in a 20% reduction in production variances.

- Led a cross-functional initiative to improve reactor cleaning procedures, decreasing downtime by 25% and extending the average run length between maintenance activities.

- Facilitated process simulation and modeling to support a $10M capital project, ensuring seamless integration with existing plant infrastructure.

- Conducted a comprehensive value stream mapping exercise for a major product line, identifying and eliminating bottlenecks that increased production capacity by 12%.

- Authored technical documentation to standardize operating procedures across the company's network of plants, fostering knowledge sharing and process consistency.

- Project-managed the installation of a new $5M distillation column, orchestrating the efforts of engineering, operations, and external contractors to deliver the project on schedule.

- Directed the adoption of lean manufacturing principles in the production process, effectively cutting lead times by 18% while maintaining product quality standards.

- Introduced and validated a novel process analytical technology (PAT) for continuous monitoring, which provided real-time data to preemptively correct deviations, improving product consistency.

- Spearheaded a capital improvement project to upgrade legacy control systems, which enhanced process reliability by 22% and reduced maintenance costs by 15%.

- Focused on sustainable process design to decrease the plant's carbon footprint; initiatives led to a 30% reduction in CO2 emissions within a 3-year span.

- Instrumental in the development of a multi-million-dollar project to retrofit and modernize a critical production facility, improving output by 20% while enhancing safety measures.

- Collaborated with R&D to pilot and commercialize a new catalyst formula, which increased process selectivity and reduced raw material costs by 10%.

- Played a key role in the facility's digital transformation by integrating IoT solutions into manufacturing systems, which led to a 15% enhancement in process visibility and control.

- Managed the selection and implementation of a new manufacturing execution system (MES), which improved operational efficiency and data accuracy.

- Authored a white paper on predictive maintenance for critical equipment, which was adopted company-wide and resulted in a 20% decrease in unscheduled downtime.

Quantifying impact on your resume

- Include the percentage reduction in process downtime achieved through optimization initiatives to demonstrate efficiency improvements.

- List the dollar value of cost savings realized from materials or energy consumption reductions to highlight financial impact.

- Document the increase in production capacity or throughput due to process redesigns to show scalability contributions.

- State the number of projects led or co-led, reflecting leadership experience and project management skills.

- Quantify the improvement in product quality or decrease in defect rates to exhibit commitment to excellence.

- Mention the amount of time reduced in the production cycle by implementing new technologies or methodologies.

- Present the size of the teams you've worked with to underscore collaboration and interpersonal abilities.

- Specify the number of patents or publications, if any, to validate innovation and domain expertise.

Action verbs for your process engineer resume

Writing your process engineer experience section without any real-world experience

Professionals, lacking experience, here's how to kick-start your process engineer career:

- Substitute experience with relevant knowledge and skills, vital for the process engineer role

- Highlight any relevant certifications and education - to showcase that you have the relevant technical training for the job

- Definitely include a professional portfolio of your work so far that could include university projects or ones you've done in your free time

- Have a big focus on your transferable skills to answer what further value you'd bring about as a candidate for the process engineer job

- Include an objective to highlight how you see your professional growth, as part of the company

Recommended reads:

- When You Should (And Not) Add Dean's List On Your Resume

- Should You Include Eagle Scout On Your Resume?

If you happen to have some basic certificates, don't invest too much of your process engineer resume real estate in them. Instead, list them within the skills section or as part of your relevant experience. This way you'd ensure you meet all job requirements while dedicating your certificates to only the most in-demand certification across the industry.

Bringing your process engineer hard skills and soft skills to the forefront of recruiters' attention

Hard skills are used to define the technological (and software) capacities you have in the industry. Technical skills are easily defined via your certification and expertise.

Soft skills have more to do with your at-work personality and how you prosper within new environments. People skills can be obtained thanks to your whole life experience and are thus a bit more difficult to define.

Why do recruiters care about both types of skills?

Hard skills have more to do with job alignment and the time your new potential employers would have to invest in training you.

Soft skills hint at how well you'd adapt to your new environment, company culture, and task organization.

Fine-tune your resume to reflect on your skills capacities and talents:

- Avoid listing basic requirements (e.g. "Excel"), instead substitute with the specifics of the technology (e.g. "Excel Macros").

- Feature your workplace values and ethics as soft skills to hint at what matters most to you in a new environment.

- Build a separate skills section for your language capabilities, only if it makes sense to the role you're applying for.

- The best way to balance process engineer hard and soft skills is by building a strengths or achievements section, where you define your outcomes via both types of skills.

There are plenty of skills that could make the cut on your resume.

That's why we've compiled for you some of the most wanted skills by recruiters, so make sure to include the technologies and soft skills that make the most sense to you (and the company you're applying for):

Top skills for your process engineer resume:

Process optimization

Statistical analysis

Chemical engineering principles

Process simulation software

Piping and instrumentation diagrams (P&IDs)

Continuous improvement methodologies

Project management

Quality control and assurance

Safety and environmental regulations compliance

Technical writing and documentation

Problem-solving

Critical thinking

Team collaboration

Effective communication

Adaptability

Attention to detail

Time management

Stress tolerance

Mention specific courses or projects that are pertinent to the job you're applying for.

Discover the perfect certification and education to list on your process engineer resume

Value the insights your resume education section offers. It can shed light on various proficiencies and experiences tailored for the job.

- Add only college or university degrees, stating the institution and duration.

- If you're nearing the end of your degree, note your graduation date.

- Weigh the pros and cons of including unrelated degrees - it might not be your best choice with so little space on your resume.

- Talk about your educational achievements if they amplify your relevant experience.

There are so many certificates you can list on your resume .

Just which ones should make the cut?

- List your prominent higher education degree in a separate box, alongside the name of the institute you've obtained it from and your graduation dates

- Curate only relevant certificates that support your expertise, hard skills, and soft skills

- Certificates that are more niche (and rare) within the industry could be listed closer to the top. Also, this space could be dedicated to more recent certifications you've attained

- Add a description to your certificates or education, only if you deem this could further enhance your chances of showcasing your unique skill set

When listing your certificates, remember that it isn't a case of "the more, the merrier", but rather "the more applicable they are to the industry, the better".

Recruiters have hinted that these are some of the most in-demand certificates for process engineer roles across the industry:

The top 5 certifications for your process engineer resume:

- Certified Six Sigma Green Belt (CSSGB) - American Society for Quality (ASQ)

- Project Management Professional (PMP) – Project Management Institute (PMI)

- Professional Engineer (PE) – National Society of Professional Engineers (NSPE)

- Certified Energy Manager (CEM) – Association of Energy Engineers (AEE)

- Lean Certification – Society of Manufacturing Engineers (SME)

The more trusted the organization you've attained your certificate (or degree) from, the more credible your skill set would be.

- How to List Expected Graduation Date on Your Resume

- Perfecting the Education Section on Your Resume

Process Engineer resume summaries or objectives: real-world samples for best industry practices

Grasp recruiters' attention from the get-go of your application with a professional Process Engineer resume summary or objective.

It's wise to select the:

- Resume objective , if you don't happen to have much experience alignment and would like to more prominently feature your dreams and personality.

- Resume summary , if you'd like to have a more standard approach to your application and feature up to five career highlights to help you stand out.

Writing your resume summary or objective should be tailored to each role you apply for.

Think about what would impress the recruiters and go from there.

But, if you need further help with this introductory section, check out some real-world samples in the next part of this guide:

Resume summaries for a process engineer job

- With over eight years of expertise optimizing petrochemical processes at ExxonMobil, my hands-on experience in streamlining operations through effective use of Six Sigma methodologies has significantly uplifted production efficiency by 23%. I seek to leverage my in-depth understanding of process simulations and advanced statistical analysis to drive performance improvements in a challenging environment.

- Adept in software development with a 5-year tenure at Google, I am equipped with a robust analytical mindset and coding expertise. My quest is now to pivot towards process engineering, utilizing my systematic approach to solving complex problems and my proficiency in Python and data structures to contribute to process optimization and workflow enhancements.

- Transitioning from a decade of experience in elite road construction management, I bring a rich knowledge of project execution, safety protocols, and logistic optimization. My ambition is to transfer this background into process engineering, ensuring effective system integration and operational excellence through relentless pursuit of continuous improvement methods.

- Enthusiastic about launching a career in process engineering, I am armed with a fresh Master's degree in Chemical Engineering from MIT and internships at DuPont which enhanced my proficiency in process design and risk management. Motivated by an objective to develop innovative solutions to drive industrial processes, ready to embrace rigorous training and collaborative work.

- Recently graduated with high honors in industrial engineering from Stanford University, I am eager to apply my understanding of production systems and supply chain management in a process engineering role. I aim to combine state-of-the-art research, practical intern experience, and my passion for sustainable manufacturing practices to improve existing processes and develop new operational strategies.

Recruiters' favorite additional process engineer resume sections

When writing your process engineer resume, you may be thinking to yourself, " Is there anything more I can add on to stand out? ".

Include any of the below four sections you deem relevant, to ensure your process engineer resume further builds up your professional and personal profile:

- Books - your favorite books can showcase that you have an excellent level of reading comprehension, creativity, and outside the box thinking;

- Languages - make sure you've included your proficiency level alongside a relevant certificate or a form of self-assessment;

- Website link - ensure you've curated your most relevant and recent projects in your professional portfolio (and that the link is a part of your resume header) to support your application;

- Passions - showing recruiters how you spend your time outside of work and what activities or causes you're invested in.

Key takeaways

- All aspects of your resume should be selected to support your bid for being the perfect candidate for the role;

- Be intentional about listing your skill set to be balanced with both technical and people capabilities, while aligning with the job;

- Include any experience items that are relevant to the role and ensure you feature the outcomes of your responsibilities;

- Use the summary or objective as a screenshot of your best experience highlights;

- Curate various resume sections to showcase personal, transferable skills.

Looking to build your own Process Engineer resume?

- Resume Examples

Signs You Hate Your Current Job and How to Find a New One

How to list patent on resume, the secret to finding keywords in job descriptions, resume job description: samples & tips to help you enhance your application, programming projects for resume: tips & examples, how long is too long of an employment gap.

- Create Resume

- Terms of Service

- Privacy Policy

- Cookie Preferences

- Resume Templates

- AI Resume Builder

- Resume Summary Generator

- Resume Formats

- Resume Checker

- Resume Skills

- How to Write a Resume

- Modern Resume Templates

- Simple Resume Templates

- Cover Letter Builder

- Cover Letter Examples

- Cover Letter Templates

- Cover Letter Formats

- How to Write a Cover Letter

- Resume Guides

- Cover Letter Guides

- Job Interview Guides

- Job Interview Questions

- Career Resources

- Meet our customers

- Career resources

- English (UK)

- French (FR)

- German (DE)

- Spanish (ES)

- Swedish (SE)

© 2024 . All rights reserved.

Made with love by people who care.

7 Process Engineer Resume Examples & Writing Guide

Need help creating a process engineer resume that gets interviews? Check out these 7 real-world resume examples and step-by-step writing guide. Learn what to include and how to structure your resume to showcase your process engineering skills and experience. Use the tips and examples to build a resume that grabs hiring managers' attention and positions you for success.

A strong resume is important for any process engineer who wants to get hired. Hiring managers look at many applications. They quickly scan resumes to find the most qualified people to interview.

This article provides 7 real examples of process engineer resumes. It also includes a step-by-step guide for how to write your own resume. With these tips and examples, you can create a resume that gets noticed.

Your resume should highlight your skills and work experience that fit the job. It should be easy to read and professional-looking. The examples and advice here will show you how to make your process engineering qualifications stand out to employers. Let's dive in and learn how to write an impressive process engineer resume.

Common Responsibilities Listed on Process Engineer Resumes

- Process design and optimization

- Equipment selection and specification

- Process simulation and modeling

- Process control and automation

- Process safety analysis and risk management

- Process validation and documentation

- Process troubleshooting and problem-solving

- Process data analysis and reporting

- Process training and knowledge transfer

- Process regulatory compliance

- Process cost estimation and budgeting

- Process scheduling and planning

- Process commissioning and start-up

- Process improvement and continuous improvement initiatives

How to write a Resume Summary

The summary or objective section on your resume serves as the first interaction between you and your potential employer. It has the potential to capture their interest and make a lasting impression, making it an integral part of your resume.

As a Process Engineer, you'll want to imbibe the essence of your skills, experience, and what you aim to achieve in this section. Let's break it down into comprehensible steps :

Emphasize on Your Field and Position

Begin by stating that you are a Process Engineer. This prevents any misunderstanding about your profession. Be specific, as it communicates that you're firmly grounded in your field and knowledgeable about your role.

Highlight Ket Accomplishments

Mention salient accomplishments from your career in Process Engineering. These could include any significant projects you've worked on, improvements you've made, or the size of the operations you've handled. Give a quantitative measure if possible, as this adds credibility and depicts the scope and impact of your work. It sends a message that you're not only experienced but also effective.

Introduce Skills and Expertise

List out your essential skills and areas of expertise, focusing on those that are relevant to the job you're applying for. Make sure to only highlight those skills that you genuinely possess and can justify. Always remember, honesty on a resume radiates authenticity and trustworthiness.

State Your Goal

A concise declaration of your career objective is a good wrap up for your summary. It can be brief - one sentence to express the kind of work you're looking for, the impact you hope to have, and why this aligns with your career goals.

To sum up, a great summary or objective section for a Process Engineer should succinctly reflect your professional identity, demonstrate your accomplishments, showcase your relevant skills and neatly line up your career trajectory. Keep it concise and to the point, while still being informative and impactful. The key is to strike the right balance.

Incorporate these measures and watch your resume transform into a captivating insight into your career as a Process Engineer, leveraging it towards an auspicious first impression.

Please note, it's always helpful to view some good and bad examples to really comprehend these aspects. Unfortunately, at this time, the imagery section is unavailable to provide you with these. When opportunities arise, do explore them for a better understanding.

Strong Summaries

- Certified Process Engineer with 10 years of experience in automotive manufacturing industry. Skilled in lean manufacturing, process optimization and Six Sigma. Proven record of implementing cost-saving measures in production process.

- Talented Process Engineer with a strong background in oil and gas industry. Proficient in material and energy balances, process control, and safety procedures. Adept at analyzing and troubleshooting process operations.

- PhD in Chemical Engineering with over 15 years experience as a Process Engineer in the pharmaceutical industry. Specializes in the improvements of pharmaceutical manufacturing processes, ensuring compliance with FDA requirements.

- Dynamic Process Engineer with proven expertise in solar cells manufacturing. Familiar with statistical process control and design of experiments. Committed to enhancing production quality and safety.

Why these are strong ?

The above are good examples because they effectively capture each candidate's strengths, qualifications and industry-sector expertise, providing potential employers with a snapshot of what each candidate can offer. They use specific keywords and phrases that may be picked up by resume-scanning software. Furthermore, they also showcase the candidate's years of experience and major achievements, making them strong selling points for the resume. It would be a good practice for job seekers to use such professional summaries at the beginning of their resumes to attract the attention of Hiring Managers.

Weak Summaries

- An engineer with some process experience.

- Worked in a factory for a couple years, did process engineering things.

- Hi! I am an engineer who did process stuff.

- I had a job as a process engineer.

- I am seeking employment as a process engineer.

- Process engineer here!

Why these are weak ?

The reason these are bad examples are mainly due to lack of specificity, professionalism, and detail. Simply stating one's title or vaguely referring to 'process stuff' doesn't convey any sense of the individual's specific skills, experience or achievements in the field. Furthermore, expressions like 'Hi!' and 'here!' are informal and inappropriate in this context. A professional summary should succinctly communicate one's value proposition to potential employers, highlighting areas of strength, key accomplishments, and the specific benefits one can bring to the organization.

Showcase your Work Experience