Advances, Systems and Applications

- Open access

- Published: 08 September 2022

Future of industry 5.0 in society: human-centric solutions, challenges and prospective research areas

- Amr Adel ORCID: orcid.org/0000-0002-0632-0940 1

Journal of Cloud Computing volume 11 , Article number: 40 ( 2022 ) Cite this article

70k Accesses

161 Citations

21 Altmetric

Metrics details

Industry 4.0 has been provided for the last 10 years to benefit the industry and the shortcomings; finally, the time for industry 5.0 has arrived. Smart factories are increasing the business productivity; therefore, industry 4.0 has limitations. In this paper, there is a discussion of the industry 5.0 opportunities as well as limitations and the future research prospects. Industry 5.0 is changing paradigm and brings the resolution since it will decrease emphasis on the technology and assume that the potential for progress is based on collaboration among the humans and machines. The industrial revolution is improving customer satisfaction by utilizing personalized products. In modern business with the paid technological developments, industry 5.0 is required for gaining competitive advantages as well as economic growth for the factory. The paper is aimed to analyze the potential applications of industry 5.0. At first, there is a discussion of the definitions of industry 5.0 and advanced technologies required in this industry revolution. There is also discussion of the applications enabled in industry 5.0 like healthcare, supply chain, production in manufacturing, cloud manufacturing, etc. The technologies discussed in this paper are big data analytics, Internet of Things, collaborative robots, Blockchain, digital twins and future 6G systems. The study also included difficulties and issues examined in this paper head to comprehend the issues caused by organizations among the robots and people in the assembly line.

Introduction

A major shift comes through the first industrial revolution (Industry 1.0) in the eighteenth century, where items were being produced by means and processes invented and allowed to be produced by machines. It started in England in 1760 and reached the United States by the end of the eighteenth century. Industry 1.0 marked a shift from the handicraft economy to dominate by machinery and impacted the industries such as mining, textile, agriculture, glass, and others [ 1 ]. The next shift to the manufacturing industry from 1871 and 1914 is termed Industry 2.0, which allowed for faster transfer of persons and innovative ideas. This revolution is a period of economic growth, increasing business productivity causing a surge in unemployment as machines replace factory workers.

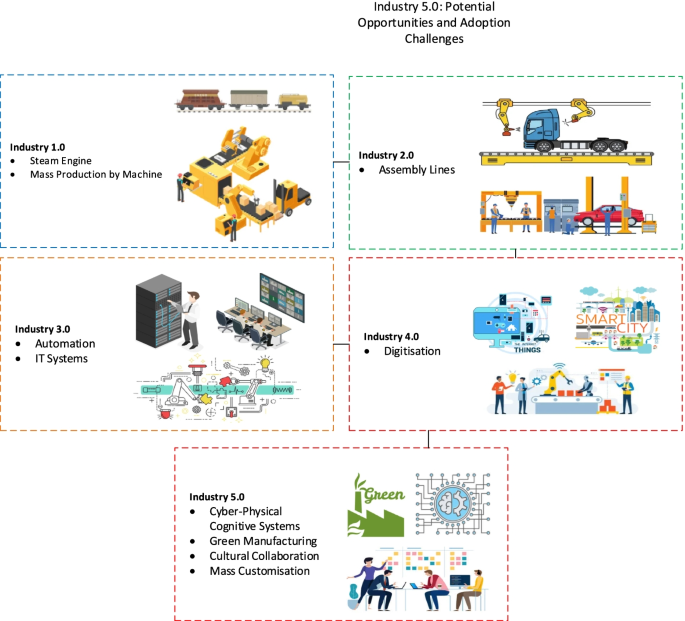

Industry 3.0 is termed the digital revolution, started in the 70s in the twentieth century through the automation of memory-programmable controls plus computers. The central point of this particular phase is mass production and the use of digital logic, integrated circuit chips; derived technologies included computers, digital cellular phones, and the internet [ 2 , 3 ]. The innovations of the technology are transforming traditional products as well as business procedures. The digital revolution is converting technology into digital format. Industry 4.0 is a union among the physical assets and advanced technologies such as artificial intelligence, IoT, robots, 3D printing, cloud computing, etc. The organizations that adopted 4.0 are flexible and prepared for data-driven decisions [ 4 ]. Industry 5.0 is the upcoming technology of the previous generation designed for efficient and intelligent machines. Figure 1 shows the industry revolution from industry 1.0 to industry 5.0. Table 1 remarks the most relevant surveys that discuss some aspects of industry X.0.

Industrial Evolution from Industry 1.0–5.0

The rationale following the progression of industry 5.0

The revolution of industry 5.0 means that humans and machines are working together, improving the efficiency of industrial production. Human workers and universal robots are boosting the productivity of the manufacturing industry [ 5 ]. Each of the executive teams of the manufacturing company is required to define the production line, then follow the key performance indicators and ensure that the processes are working effortlessly. The future direction of industry 5.0 is the manufacturing of robots and industrial robots. The advancement of artificial intelligence and cognitive computing technologies is taking the manufacturing world to a high speed and increasing business efficiency [ 20 ]. Apart from the benefits in the manufacturing business, industry 5.0 also benefits in sustainability as it aims to develop a sustainable system that runs on renewable energy.

In order to adopt industry 5.0 for the companies, the personnel are required proper interaction among the machines as well as operators. It is knowledge in the fields like robotics as well as artificial intelligence [ 21 , 22 ]. The role of the business organization is based on making decisions around the advanced factors. Training employees is required with virtual education to decrease the cost for the businesses, as it is not required production to stop for providing training to the employees. It provides safe training that can prevent the workers from being uncovered to needless issues during the training sessions. Communication and employee motivation are boosted by resulting in interactive knowledge environments [ 1 , 6 , 23 , 24 ]. The employment positions are related to communication with the robotics systems as well as artificial intelligence.

Collaborative robots are being designed for intuitive interaction with humans. Expansion of the digital twins is required technology in industry 5.0. Visual models of the products, processes, and generation will allow better understanding and testing. The Nexus Integra platform is the software required to drive the transformation of the industrial business in industry 5.0 [ 7 ]. It is an integrated system for the large-scale management of industrial assets, allowing companies to leap towards digital transformation. Previous generations adapted lifestyles to what machines can do [ 25 , 26 ]. Still, industry 5.0 differs from all previous resolutions, as humans are at the present face with the center in production procedures.

Contributions of the paper

The significance of the survey has set to defining the definitions and features of the fifth generation from the literature sources that can help understand the term industry 5.0 from the perspectives of various authors. There is also a discussion of various features of Industry 5.0 as compared to the industrial evolutions. Moreover, there is a discussion of the applications to develop and enable in industry 5.0 like the healthcare, supply chain, production in manufacturing, cloud manufacturing and others. The key technologies of industry 5.0 are also discussed in this paper, including big data analytics, Internet of Things, collaborative robots, Blockchain, digital twins and future 6G systems. Finally, this paper also discusses the challenges to understand the issues related to robots and humans in manufacturing factories. There is a highlighting of the future direction of the research work towards the realization of Industry 5.0.

Structure of the paper

In section 2, there is reviewing of the definitions of Industry 5.0 from the literature sources with added features of 5.0 in comparison with the past industrial revolutions. The applications are also discussed in this paper in section 3. Later, the enabling technologies for industry 5.0 are discussed in section 4, such as big data, IoT, cloud computing, 6G networks, Blockchain. Section 5 highlights. Finally, in section 6, the conclusion is provided with summarizing the entire paperwork.

Explanations and modernization

Explanation of definitions.

The term Industry 5.0 refers to people working with robots and smart machines. It is about robots helping humans work faster by leveraging advanced technologies such as big data analytics [ 27 , 28 ].

Industry 5.0 is termed as the revolution in which man and machine are findings ways to work for improvement means and efficiency of the manufacturing production [ 29 ].

Ocicka and Turek [ 30 ] suggested that Industry 5.0 is compelled with various industries technologists, philosophies, and others to focus on the human factors and technologies in the manufacturing systems.

Industry 5.0 is considered the edge of the smart factory, where it communicates with robots and humans [ 13 , 31 ]. It uses social networks for communication purposes among humans and electronics components.

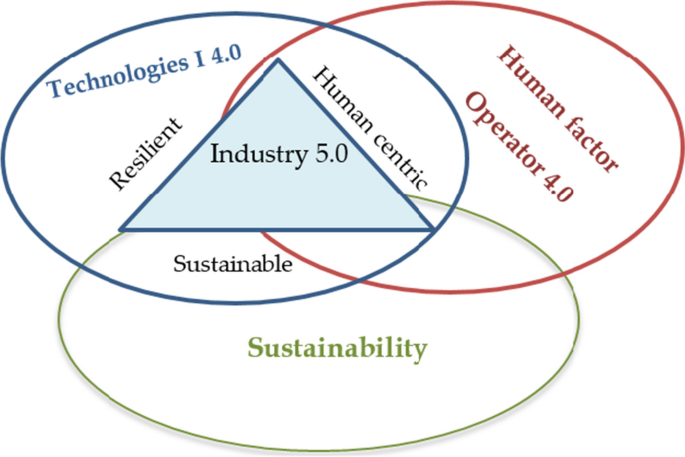

Industry 5.0 added human-centric, sustainable, and resilient concepts to the industrial revolution. It will revolutionize the manufacturing systems worldwide by preventing repetitive tasks from human workers [ 32 ]. The intelligent robots will penetrate manufacturing supply chains as well as the workflow of the production to unparalleled levels.

Added features of industry 5.0

Industry 5.0 is taking over the past improvements, and it is an effective process due to its highest level of perfection, and the machine work reduces the time and effort of the human workers [ 33 ]. Apart from the challenges, a few features encourage business organizations to implement industry 5.0. For instance, in the medical sector, the professionals are working on in the direction of creating a synthetic pancreas. This project has not yet finalized. The sufferers who diagnosed with Type-1 diabetes have been provided with monitoring device that checks blood and levels of sugar in their blood. This device is interconnected with another device that has the capability to deliver the insulin into the body. This is one of creative technologies that has been developed and personalized for patients in terms of providing a reliable and handy control system for the patient. Industry 5.0 is taking this personalization to the next level as it enables the medical doctors to provide the patients with an application that they can install on their smart phones, so they can be traced by their lifestyle and daily routing and a customized plan can be made for them. This would be a life-changing for the Type-1 diabetes sufferers, as the technologies utilized are based on artificial intelligence (AI) systems. These AI systems have the capability to understand and learn the different reactions of the body and act accordingly.

Increase the maintenance plan: Predictive maintenance is required for the smart sensors, IoT, customized software as it requires proper monitoring and maintaining of the failures in the smart devices. The machines will probably break down, and a maintenance plan will stop it [ 34 , 35 ].

Sustainability: Industry 5.0 is promising to use the resources adjusted to the current requirements of the manufacturing industry. Collaboration among humans and machines leads to supple business models. Waste along with overproduction is to be reduced to eliminate it. Along with new efforts, local production makes economics sustainable [ 8 , 36 ]. With industry 5.0, corporate technologies are changing the trend. It leads to the emergence of sustainable policies, like minimal generation of the waste and management that can make the companies as effective. Industry 5.0 is created to be applicable through purposefully concentrating on creative research as well as setting knowledge at the frontline of the evolution. It is considered as being marked by a determination that is more than just manufacturing goods for profit. The fundamental principles of Industry 5.0 are: sustainability, human-centricity, and resilience.

The efficiency of humans and productivity: Advanced technologies bring people back to the production center. Collaborative robots perform repetitive and dangerous jobs while people focus on creativity and efficient business solutions [ 37 ]. The skills are led to an increase in business productivity, where people feel motivated to do the work and receive the results. A human-centered methodology highlights human demands over the manufacture procedure. Producers have to recognize what technology can do for the people and focus on how technology can adjust to the requirements of the worker instead of the other way. It is essential that technology tackle autonomy and privacy issues.

Environmental control: Smart and connected sensors and customized software provide a real-time predictive overview of the climate, temperature, consumption of energy, and others [ 38 ]. It is helpful for business firms to prevent losses and improve production. For maintaining the sustainability of the manufacturing process, it must improve iterative procedures that repurpose, recycle and recover assets. Environmental influence has to be decreased. Sustainable manufacturers can utilize the developed technologies, for example, artificial intelligence to boost personalization, which minimize waste and optimize source-productivity.

Forecast line production efficiency: Smart and connected machines, machine learning, industrial automation is forecasting the efficiency of the production based on the existing activity. It increases business efficiency, where the processes are to be adjusted based on the parameters to avoid losses [ 39 ]. Manufacturers need to improve a higher level of resilience in production to enhance and defend their industrial production against disturbances and disasters such as covid-19.

Creativity: Technological innovations are not allowing for a degree of personalization that can meet with demands of the customers. Personnel is part of industry 5.0, which can leverage the potential of the technology [ 40 ]. It finds ways to provide new ideas that can lead to product development with personalization in mind.

Modernizations and innovations

Industry 5.0 is evolving in different domains such as healthcare, manufacturing, textile, education, food, and others. The products are discussed by Bundesgartenschau [ 41 ], a woollen pavilion with the robot hand developed by a joint venture of the businesses. KR 500 FORTEC robot is being used as the product. It can perform various types of carpenter tasks like moving the components, applying adhesives, and enabling the robots to collaborate.

By adopting industry 5.0, most industries are moving towards the smart social factory. The project selected to better understand the concepts of industry 5.0 is an intelligent management project of Repsol. The business is employed in the Blockchain, robotic processes automation technology to enhance the security and productivity of the business. The automated guided vehicle is the first Cobot of Repsol that carries out the logistics works such as deposition of waste, delivery of the raw materials from warehouse and lab visualization. Repol is conducted on the project Block lab, where the business is transmitting sensitive data through the property of Blockchain [ 42 , 43 , 44 , 45 , 46 , 47 ]. The project is designed to streamline the samples of safety issues, and it is properly managing 10,000 samples every year.

Industry 5.0 creative applications

Smart hospital.

Industry 5.0 is aimed to create a smart hospital with real-time capability. The technology can provide remote monitoring systems within healthcare [ 48 ]. It plays a key in making life better for the doctors. In the COVID-19 pandemic, doctors can use this smart healthcare technology to focus on infected patients and provide efficient data regarding better treatment [ 1 , 49 ]. Even it also helps the students as well as medical students for needed medical training through the outbreak of COVID-19. Machine learning (ML) is applied to medical imaging, natural language processing, plus genetic data [ 7 ]. It is focused on the diagnosis of the diseases, detection, plus prediction of the diseases.

Abdelmageed and Zayed [ 50 ] mentioned that industry 5.0 allows manufacturing of the personalized smart implant properly as per the change in requirements of the customers. The medical professional is moving towards artificial intelligence technology to measure various problems like glucose levels. It helps implement mass personalization by producing implants per the patent match, which are the initial needs for orthopedics [ 51 ]. Even there is a change in the traditional method manufacturing of the implants of patients, and it is also capable of upgrading various medical devices plus tools. The technologies are used in revolution as it is helpful to perform the surgery in a precise manner [ 10 , 52 ]. It is helpful for medical students to provide better education, learning, and research and expansion procedures [ 53 ]. In orthopedics, industry 5.0 requires high-quality implants with an extended life that is personalized. It helps solve various challenges like over-production, wring selection of the tool and lack of transparency [ 35 , 54 , 55 ].

Manufacturing industry

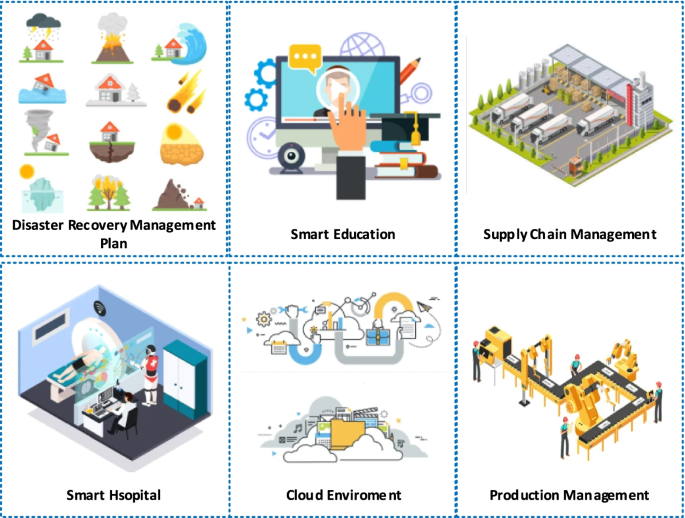

Industry 5.0 is considered a new production model where it is focused on interaction among humans as well as machines. Industry 5.0 is involved in leveraging collaboration among increasing accurate machinery plus the innovative potential of human beings. In order to make manufacturing sustainable, it develops processes that repurpose and recycle the resources [ 56 , 57 ]. There is also required to reduce the environmental impacts in the manufacturing industry. Additive manufacturing is required to increase personalization to optimize resource efficiency and waste. Industry 5.0 is revolutionizing the manufacturing systems across the globe by taking away repetitive tasks from human workers. Brown and Wobst [ 58 ] illustrated that intelligent robots and systems are penetrating supply chains and manufacturing shop floors to an unparalleled stage. Smart manufacturing allows designers to protect design files of manufacturing items by storing them in the cloud with robust access control and usage of the manufacturing resources across various places [ 59 ]. Figure 2 pictorially illustrates a number of potential applications within industry 5.0.

Applications of Industry 5.0

Ghobakhloo et al. [ 60 ] defined that the designers are permitted to place the manufacturing plants close to raw material and the areas with low manufacturing costs. Control of machines in the plant and operations of the manufacturing lifecycle is to be handled by cloud manufacturing [ 61 ]. The service-oriented model helps manufacturing integrate production abilities with the services to provide the clients with proper solutions. Through the business innovations, adding service factors to the production process aims to improve production efficiency, value-added, and the market share for the manufacturing business [ 9 ]. The cloud-based platform controls the manufacturing services, and it is used in a cost-optimized way. Cloud manufacturing is networked as well as a distributed system for the production resources.

Supply chain management

Nguyen et al. [ 62 ] determined that supply chain 5.0 highlights the importance of collaboration among smarter machines like COBOTS and humans [ 63 ]. Industry 5.0 is aimed to cater to hyper-personalization moreover hyper-customization requirements of the customers, which require combine of human originality plus the competence of the machines. Robots are required for the supply chain management in standardized procedures in high production volumes, added this to each product, and it is a challenge where the robots are required proper guidance [ 64 ]. Babamiri, Bahari and Salimi [ 40 ] mentioned that the human touch is not required to customize and personalized products. Still, it also ensures seamless end-to-end processes of the supply chain, such as selecting the raw materials to comprehend its personalization and customization needs for the individual consumers. Industry 5.0 seeks to take automated and intelligent digital ecosystems and pair them with the human touch [ 65 , 66 ]. There is leveraging of human elements in such a process that it helps customize the end-user experiences and optimized workflows.

Human intelligence is worked with the empowered way with cognitive computing along with intelligent automation abilities to enable hyper-personalization. The technologies like machine learning, robotic automation, and others are helping the employees increase business proficiency and deliver high value to the customers faster [ 12 , 67 ]. From delivering the raw materials, transactions, transportation, the ERP system manages the supply chain for the business organization [ 68 ]. The next generation of supply chain solutions is making and deploying the technology to empower the digital supply chain. It means bringing customization to the supply chain, improving the customers’ satisfaction and the management of the business efficiency and market margins. There is the reduction of the risks related to supply chain and wastages based on the existing information of the business. Ietto et al. [ 32 ]concluded that there is the improvement of the supply chain integration for the strategic partnerships and enabled the supply chains to spend time on the experimentation plus less on the fighting forces on matters for the project executions.

Industry 5.0 technologies

The enabling technologies related to industry 5.0 include cloud computing, Blockchain, analytics of big data, IoT and 6G networks.

Cloud computing

Cloud computing is the delivery of computing services those are included databases, software, intelligence analytics, networks, and others [ 69 ]. This technology is offering efficient innovation and economics of the scale. This technology uses the internet to store and manage data on the remote servers, and then data is accessed via the internet. It delivers on-demand computing services from applications to storage plus processing power [ 58 , 70 ]. The industrial cloud is the virtual environment that provides a supportive environment for industry applications [ 71 , 72 , 73 ]. The cloud providers are manufacturing applications like IoT monitoring tools adopted for mobile and web usage. The cloud also supports the usage of API that can automate data normalization from diverse data production sources [ 74 ]. Edge computing devices handle data analytics equipped with limited computing resources to manage the business analyses. Global cooperative type of typical cloud ecosystems in critical sectors is pictorially demonstrated in Fig. 3 .

Cloud Ecosystems in Critical Sectors

According to Haleem, Javaid and Khan [ 75 ], cloud computing provides a scalable infrastructure to support data edge devices. The cloud infrastructure backs edge IoT platforms. The platforms are being used to manage the edge devices like autonomous robots and diverse robots deployed on the shop floor. In order to manage critical data, the industry is access to the data from the local servers daily. Industry 5.0 can reduce the volume of data sent to the centralized server [ 76 ]. Cloud computing allows preventive data to detect machine failures and mitigates them by continuing with more workforce.

Collaborative robots

Industry 5.0 aims to put the human touch back in development and production. It grants the human operators with benefits of the robots like technical precision and heavy lifting abilities [ 77 ]. There is a high ability of humans to perform critical tasks, allowing the introduction of a high degree of control and the capability to individualize the production phases [ 78 ]. One of the significant implications of collaborative robotics as well as Industry 5.0 is required for human inputs that can extend the existing iterations. Collaborative robots, as well as industry 5.0, are representing new age in robotics plus production. Industry 5.0 plus Cobots is the heart that can combine people’s creativity and craftsmanship with the efficiency and constancy of the robots [ 62 , 79 , 80 ]. From people-centric, the customized products and specialist skills are made more available. Industry 4.0 is focused on ensuring consistency of the quality and data collection.

In contrast, industry 5.0 focuses on highly skilled people plus robots to create individualized products from smart devices to cars for consumers [ 81 ]. With industry 5.0, the robots are started to work together. The collaborative robots are accomplished with the tasks of heavy lifting plus ensured consistency, while skilled humans are provided cognitive skills of the craftsperson [ 82 , 83 ]. It is to be expected that robots are changing relations among humans plus machines in the context of production.

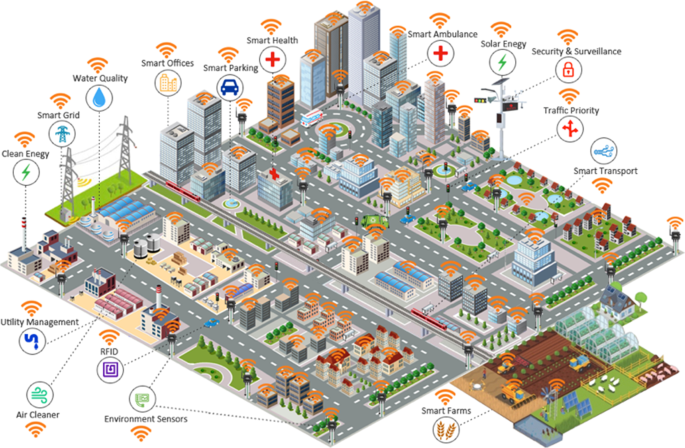

Industry 5.0 refers to people working with robots and smart machines. Robots are helping humans work better by leveraging advanced technologies such as the Internet of things. It added a human touch to industry 4.0 for automation plus business efficiency [ 11 , 75 , 84 , 85 , 86 ]. It is described as a network of physical objects and things embedded with sensors, software, and other technologies. It is a way to connect and exchange data with the devices plus systems over the internet. Ghobakhloo et al. [ 60 ] mentioned that IoT is a new paradigm that is to be changed the traditional way to live in the high-tech lifestyle. The research is done to enhance the advanced technologies through IoT. Even IoT is considered a way to provide efficient solutions to data and information security problems. There is the development of secured interaction among social networks plus privacy issues, as it is a hot topic in IoT developers [ 87 ]. The smart city is considered an important area for IoT as it incorporates smart homes. It contains IoT-enabled home appliances, heating systems, security systems, and others communicating with each other to provide better comfort and reduce energy [ 30 ].

Sinclair et al. [ 77 ] concluded that authentication plus access control are the issues in IoT; those are required to have promising solutions to have strong security. A solution is required to verify communication parties to decrease the loss of sensitive data. It is provided with an authentication scheme and verifies various security threats such as man-in-the-middle attacks the key security controls. The proposed authentication and access control approaches help to provide authenticity plus confidentiality end-to-end latency in IoT based on the communication network. It is a dynamic approach for the data-centric applications concerning the cloud platforms.

Big data analytics

Industry 5.0 is an innovative technology that enables utilizing 3D symmetry in the innovation ecosystem designs. Matheus et al. [ 70 ] mentioned that big data analytics is a complex procedure to examine big data to uncover data like hidden patterns, trends of the markets and others. It uses an advanced analytic method with diverse data sets, including structured and semi-structured data. It has massive data sets to store and process through traditional tools [ 15 , 88 , 89 ]. It is used as real-time data to enhance the competitive advantages of the business industry, focusing on providing possible recommendations on predictive discovery. Big data analytics is used to recognize discrepancies while the organization is leveraging a list of the root causes of the issues. Most businesses use big data analytics to make strategic decisions [ 90 , 91 , 92 ]. The business uses various factors like population, location accessibility and others to get details of the customer preferences. There is the improvement of the customer experiences by monitoring the customer experiences and addressing problems solutions to build strong customer relationships [ 93 , 94 ]. Even big data is a challenge for industry 5.0 when detailed information is not gathered on the manufacturing cycle.

It is decentralized and distributed technology, where the digital ledger contains records named as blocks to record the transactions data. It is a shared ledger that can facilitate recording the transactions and tracking the assets in the business network [ 95 ]. The business is running on the information. Therefore, Blockchain technology delivers the data by providing shared and completed information stored in the immutable ledger that the network members access [ 96 , 97 , 98 , 99 ]. Blockchain technology helps the customers by tracking the orders, payments, production, etc. The network participants have distributed ledger records of transactions, which are recorded to avoid duplication of efforts and records in the database system [ 100 ]. In order to speed up the transactions, a smart contract is stored on Blockchain and is to be executed on an automatic basis. It is defined as conditions for the corporate, including terms for paid travel insurance [ 100 , 101 , 102 ]. The transactions are to be blocked in irreversible chains, and it strengthens verification of previous blocks plays the entire Blockchain transaction is done. Data accuracy is required for the business to validate the transactions, which are recorded [ 103 , 104 , 105 ]. With the distributed ledger, network members share, so time wastage is eliminated.

6G and beyond

It is a sixth-generation standard for developing wireless interactions technologies that can support cellular data networks. 6G organizations are relied upon to display significantly greater heterogeneity than their ancestors [ 106 ]. They will probably help applications past current portable use situations, like virtual and increased reality (VR/AR), omnipresent moment correspondences, and inescapable knowledge of the Internet of Things (IoT). Normally, versatile organization administrators will embrace adaptable decentralized plans of action for 6G, with nearby authorizing, range sharing, framework sharing, and wise mechanized administration supported by versatile edge processing, artificial brainpower, short-parcel correspondence and Blockchain advances [ 107 ]. For industry 5.0, 6G networks are expected to meet the intelligent information society standards to deliver ultra-high reliability [ 108 ]. Artificial intelligence methods are used to get mobility predictions solutions to ensure network connectivity. The challenge of industry 5.0 included a high data rate for various applications [ 109 ]. As large smart devices are connected, energy management is an issue for industry 5.0. There is the optimization of energy management through the usage of energy consumption plus methods of energy harvesting.

Challenges of industry 5.0

With around industry 5.0, it is easier to overlook the potential challenges. The challenges are being identified and solved for industry 5.0 developments to succeed for the business.

People are required to develop competency skills, as working with the advanced robots, the human workers are required to get knowledge about collaboration with the smart machine and robot manufacturer [ 110 ]. Apart from the soft skills required, gaining technical skills is also an issue for human workers [ 2 , 101 ]. Programming to the industrial robot and managing translation in the new jobs are difficult tasks requiring a high level of technical skills.

Adoption of advanced technology is required more time and effort from the side of the human workers. Customized software-connected factories, collaborative robotics, artificial intelligence, real-time information, and the internet of things must be adopted for industry 5.0 [ 50 , 111 , 112 , 113 ].

Advanced technologies are required investments. UR Cobot is not coming cheap. Training the human workers for new jobs is bringing extra costs. The companies are found it difficult to upgrade the production lines for industry 5.0 [ 114 ]. Adopting Industry 5.0 is expensive as it requires smart machines and highly skilled employees to increase productivity and efficiency.

Security is a challenge for Industry 5.0 as it is critical to establish trust in ecosystems. The authentication is used in the industry is the scale to interact with various devices, to stand against the future quantum computing applications to deploy nodes of IoT [ 60 , 94 , 115 ]. Usage of artificial intelligence and automation in industry 5.0 are threats for the business, and therefore it is required to have trusted security for it [ 88 , 116 , 117 , 118 ]. The applications of Industry 5.0 are focused on the ICT systems, and therefore it leads to strict security requirements to prevent the security challenges.

Lessons learned

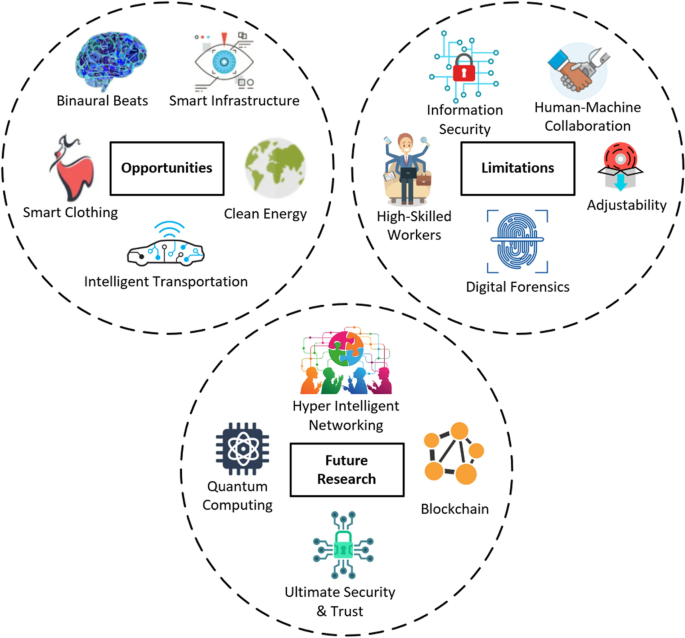

The evolution of Industry 5.0 is done in the retail, healthcare, finance, manufacturing and other industries. The lessons learned are discussed from various studies, applications, and enabling technologies of Industry 5.0. Figure 4 illustrates the opportunities, limitations, and future research directions on industry 5.0.

Opportunities, Limitations, and Future Research of Industry 5.0

Definitions of industry 5.0

From definitions of Industry 5.0, it is being observed that it is an innovative production model where the focus is based on interaction among humans and machines [ 56 , 119 , 120 , 121 , 122 ]. It is involved with leveraging collaboration among increased power and efficient machinery and innovative potential of human beings. The existing projects based on which industry 5.0 is conducted related to the optimization of artificial intelligence that leads to customized products [ 18 , 46 , 123 , 124 , 125 , 126 , 127 , 128 ]. There is the adoption of this industry at the international standards.

Applications of industry 5.0

Industry 5.0 provides benefits for the industry for both the workers and society. There is also an increase in the competitiveness of the business and help attract the best talents [ 129 , 130 , 131 ]. Adoption of this industry supports technologies that make natural usage of the resources properly. Human robotics, such as Sophia, personifies dreams of the future of artificial intelligence [ 132 , 133 ]. It helps in the decision making of humans and is supported by enabling technologies that help in revolutionize various sectors. Even various challenges are mentioned in this paper, like handling quantity of data, managing resources, and others.

Enabling technologies

The enabling technologies of industry 5.0 are set for complex systems that can combine the technologies such as smart materials, human-machine interaction, big data analytics, cloud computing, and others [ 134 ]. Smart manufacturing and intelligence help reduce network traffic, facilitate transactions, and privacy, which helps the business use software resources to exchange data about the industrial sectors [ 135 ]. Blockchain technology is automated agreement processes among various stakeholders, while smart contracts manage security, authentication, and automated service-related actions [ 136 , 137 ]. 6G network is expected to meet with the intelligent information standard that provides high energy efficiency, high reliability, plus capacity of traffic. Big data analytics is the enabling technology that helps manage a large amount of data [ 17 , 116 , 138 ]. Even the internet of things is an opportunity for industry 5.0 that can reduce operating costs by eliminating issues on the communication network, waste management, supply chain, production process optimization, and others.

Limitations of industry 5.0

Acceptance of technology and trust in the technologies are critical. Adaptation of the technology to humans coincides with training people who are using the new technologies [ 139 , 140 , 141 , 142 , 143 ]. Current challenges are security, privacy, lack of skilled workers, time-consuming process, and large budget required. Adoption of industry 5.0 is required to follow industrial laws and regulations that can help to work together with smart machines plus cobots. Future directions for industry 5.0 are cognitive computing, human and machine interaction, and quantum computing.

Future directions

Cognitive computing: This application aims to stimulate the thoughts of the human in processes into a computerized model [ 16 , 144 , 145 ]. Using the self-learning algorithms uses data mining, recognition of patterns, natural language, and others that the computer can read that the human brain will work.

Human and machine interaction refers to communication with interaction among humans and machines via the user interface. Natural user interfaces like gestures are used to gain attention as they allow humans to control the machines through intuitive and natural behaviours [ 86 , 146 , 147 , 148 , 149 ]. It is the future direction for industry 5.0 as it helps to keep the humans at the centre of the system and technologies to build in. Even the user interface helps people understand people’s behaviour and motivations.

Quantum computing is a type of computation that can harness collective properties of the quantum states, like interference entanglement, to do the calculations. The devices are performed quantum computations which are defined as quantum computers [ 8 , 150 , 151 , 152 , 153 ]. It is performing calculations focused on the probability of the object’s state before it is measured.

From the study, it is concluded that the author started the work with definitions of industry 5.0 from the perspective of the industrial as well as academic communities. Even the applications have also been discussed that help better understand the features of industry 5.0, followed by a discussion of enabling technologies. Industry 5.0 concept is designed to make the efficiency of humans and machines correctly. Challenges are also presented in this paper that help manage the issues caused in industry 5.0. Future directions are discussed in this paper that should be handled better to use this industry shortly.

Acknowledgements

The authors would like to thank the anonymous reviewers for their insightful comments and suggestions on improving this paper.

The authors declare that they have no funder. It is aimed to find a funder through OA funding service.

Author information

Authors and affiliations.

Yoobee College of Creative Technologies, School of Technology, Auckland, New Zealand

You can also search for this author in PubMed Google Scholar

Contributions

The author was responsible for the data collection, analysis of the literature review, and paper organization. The author(s) read and approved the final manuscript.

Corresponding author

Correspondence to Amr Adel .

Ethics declarations

Competing interests.

The authors declare that they have no competing interests.

Additional information

Publisher’s note.

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/ .

Reprints and permissions

About this article

Cite this article.

Adel, A. Future of industry 5.0 in society: human-centric solutions, challenges and prospective research areas. J Cloud Comp 11 , 40 (2022). https://doi.org/10.1186/s13677-022-00314-5

Download citation

Received : 27 February 2022

Accepted : 24 July 2022

Published : 08 September 2022

DOI : https://doi.org/10.1186/s13677-022-00314-5

Industry 5.0 - Towards a sustainable, human-centric and resilient European industry

Description.

Industry 5.0 complements the existing Industry 4.0 paradigm by highlighting research and innovation as drivers for a transition to a sustainable, human-centric and resilient European industry. It moves focus from shareholder to stakeholder value, with benefits for all concerned. Industry 5.0 attempts to capture the value of new technologies, providing prosperity beyond jobs and growth, while respecting planetary boundaries, and placing the wellbeing of the industry worker at the centre of the production process.

By Maija Breque, Lars De Nul, Athanasios Petridis (DG RTD)

Related links

Share this page

Industry 5.0: improving humanization and sustainability of Industry 4.0

- Published: 27 April 2022

- Volume 127 , pages 3117–3144, ( 2022 )

Cite this article

- Sandra Grabowska ORCID: orcid.org/0000-0002-0478-3466 1 ,

- Sebastian Saniuk ORCID: orcid.org/0000-0002-9014-036X 2 &

- Bożena Gajdzik ORCID: orcid.org/0000-0002-0408-1691 3

14k Accesses

109 Citations

5 Altmetric

Explore all metrics

The widespread digitization and dynamic development of the technologies of the fourth industrial revolution, leading to the dehumanization of industry, have increased the interest of the scientific community in aspects of industrial humanization, sustainability and resilience. Hence, the aim of the article is to identify areas related to humanization and sustainability of the concept of Industry 4.0. A bibliometric analysis of Web of Science using Vosviewer tools, Excell and content analysis of selected papers were applied. The most important results include the determination of the dynamics of the increase in the number of publications in the segment of Industry 4.0 and Industry 5.0. The article indicates the weaknesses of the concept of Industry 4.0, especially in the area of the role of man in smart factories and sustainable development. Thus, the framework of the concept of Industry 5.0 was identified. In addition, the bibliometric analysis carried out allowed the identification of an important stream of employee skill development.

Similar content being viewed by others

Industry 4.0 Contributions in Sustainable Operations

Future Research Agenda to Understanding the Sustainable Business Model in Industry 4.0

Challenges of Albanian Companies for Sustainable Development in the Era of Industry 4.0

Avoid common mistakes on your manuscript.

Introduction

Difficulties in defining the Industry 4.0 concept have existed since its inception in 2011, finally accepted that Industry 4.0 is a set of technologies capable of creating cyber-physical systems inside companies and in supply chains (Kagermann et al., 2015 ). The assumptions of the Industry 4.0 concept formulated in the publications of Prof. K. Schwab ( 2017 , 2018 ) have not yet been fully realized, because technological investments require high financial resources. Until 2020, the German industry has invested a total of euros 40 billion in Industry 4.0 every year. The annual investments in the European industrial sector are as high as euros 140 billion (Geissbauer et al., 2016 ). There is a great potential for companies' digital transformation, but the global progress results are still small. In some industries, change is progressing faster than in others. Based on the indicators used by the EU to monitor the level of digitization (DESI), it can be concluded that the biggest challenge for companies is still the integration of digital technology with the digitization of services. There is still a lot to do in the way of transformation of companies to Industry 4.0. The critical elements are high investments and the pace of implementing technological changes in companies from various industries. Companies realise the development visions of Industry 4.0 and work on changes for "Vision 2030". An opportunity for accelerating technological development is the 5G network and government programs supporting digital technologies and policies for digitalization of societies and economies, such as, e.g. RFCs, PR7, EUREKA, SPIRE.

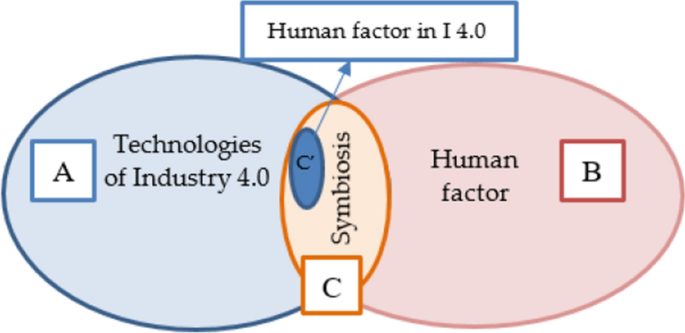

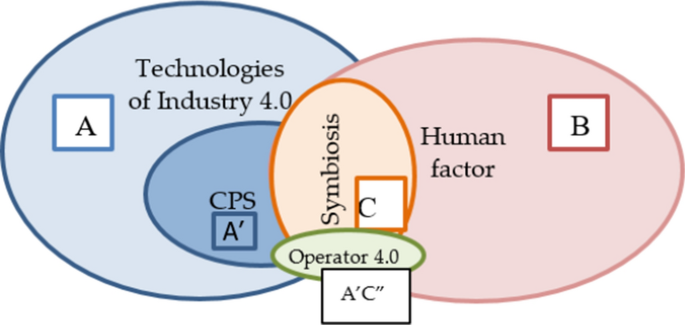

Industry 4.0 builds cyber-physical production systems to integrate information technology and operational technology in enterprises and supply chains. The evolution of industrialization from Industry 4.0 to Industry 5.0 is dictated primarily by the need to expose man's role in cyber-physical systems. Technologies used to build Industry 4.0 cannot impose their choices on people but offer them to them. The first mentions of the role of operators in Industry 4.0 appeared in the publications of Romero et al. ( 2016 ). It was emphasized that symbiosis between humans and new technologies is needed. The authors proposed to introduce the human factor into cyber-physical systems. The new system design is called Human Cyber-Physical System (H CPS). The humanization of the built technological environment for Industry 4.0 was one of the first factors in the evolution of Industry 4.0 towards Industry 5.0. Nowadays, apart from the human factor, the authors noted research gaps in sustainability, responsibility, safety, and others in the Industry 4.0 concept (Longo et al., 2020 ).

Saniuk et al. ( 2020 ) attempted to systematize the barriers of Industry 4.0 in the following categories: social and market, concerning particular groups of stakeholders of changes. Other authors (scientists, researchers) also participated in discussing social and environmental problems (gaps) of Industry 4.0. Ranghino ( 2019 ) undertook a discussion about environmental risks. Bonilla et al. ( 2020 ) wrote about the impact of Industry 4.0 technology on the environment and sustainability, creating optimistic and pessimistic scenarios. The sustainability aspect of Industry 4.0 was also a topic of publication: Gajdzik et al. ( 2020 ), Luthra and Mangla ( 2018 ), Lopes et al. ( 2018 ), Pagoropoulos et al. ( 2017 ) and others. Gajdzik et al. ( 2020 ) discussed the place and role of sustainability in the concept of Industry 4.0. Luthra and Mangla ( 2018 ) presented a topic about sustainability in the supply chain, and Lopes et al. ( 2018 ) about Industry 4.0 and the circular economy. A similar topis was analyzed by Pagoropoulos et al. ( 2017 ) but in the influence of digital technologies on the circular economy. At the same time, Terlau and Hirsch ( 2015 ) discussed sustainable consumption in the development of industries and economies. Sustainable Manufacturing in Industry 4.0 topic was presented by Stock and Seliger ( 2016 ). Thus, the issues of discussion were many. Their goal was to seek consensus among the various communities (scientific, political, business) on the need to incorporate social and environmental priorities in industrialization better. According to European Commission (EC), the power of Industry 5.0 is a societal goal beyond jobs and growth to become a resilient provider of prosperity by making production respect the boundaries of our planet and placing the well-being of the industry worker at the centre of the production process (Document EC, 2021 ).

The authors of this publication, joining the discussion about the evolution of Industry 4.0 towards Industry 5.0, analyzed the research gaps of Industry 4.0 based on a review of the topics of publications in the WoS scientific database, which served to initiate a discussion about the new directions of industrial development, defined, according to the time chronology of industrialization—Industry 5.0.

The article aims to identify areas related to humanization and sustainable development of the concept of Industry 4.0. In addition, the article identifies the weaknesses of the Industry 4.0 concept, especially in the role of human resources in smart factories and sustainability, which are reported by scientists and researchers in numerous scientific studies.

The bibliometric analysis methodology was used, which is the most suitable for studying the evolution of areas of scientific research conducted in the field of transformation of the Industry 4.0 concept into the Industry 5.0 concept. As one of the quantitative methods, the bibliometric analysis allowed determining the state and development trends of the literature in the subject of the evolution of the Industry 4.0 to Industry 5.0 concept. According to M. Norton, bibliometric analysis is a method of evaluating research results and a comprehensive view of current scientific achievements. It is based on the use and quantification of quantitative data in scientific papers and quantitative indicators of various databases. It is a measure of texts and information (Norton, 2001 ).

The article consists of the following sections: Introduction, Industry 4.0 towards Industry 5.0, Material and methods, Results and discussion, Conclusions. In the Industry 4.0 towards Industry 5.0 section, the authors presented the Industry 4.0 concept and the need to humanize the industry, paying attention to the aspects of sustainable development and resilience. Furthermore, the authors presented an outline and origins of the Industry 5.0 concept. Based on selected publications, the authors paid attention to the directions of the conducted research in this area. In Material and methods section, the authors presented the research methodology, selecting bibliometric analysis segments and the justification for choosing the Web of Science (WoS) database. The Web of Science ™ Core Collection database was used for research purposes because it is the most widely used database and citation database. This database is also considered the most consistent. Vosviewer and Excell software were used. The Results and discussion section describes the research results obtained based on bibliometric analysis and the analysis of the content of selected publications in the Industry 5.0 area. The article ends with a Conclusion section containing the conclusions, limitations of the conducted research and directions of future work.

Industry 4.0 towards Industry 5.0

Industry 4.0 means the integration of intelligent machines and systems and making changes in production processes to increase production efficiency. Industry 4.0 is about resilient technology, new ways of working, and the role of people in the industry (Luthra & Mangla, 2018 ). The changes occurring in Industry 4.0 include a wide range of innovations at the level of plants and factories belonging to various industries and services and the functioning of entire societies. Industry 4.0 is essentially a trend toward automation and data sharing in manufacturing technologies and processes that include Cyber-Physical Systems (CPS), the Internet of Things (IoT), Cloud Computing, Cognitive Computing, and Artificial Intelligence (Lee et al., 2015 ).

In the media and literature, the perception of Industry 4.0 in terms of technological changes that should be implemented in manufacturing companies is dominant. Still, this industrial revolution, its trends and effects are visible in all macro and micro areas of the market. The proposed technological changes, which have taken on strategic importance in the thinking and actions of many market participants, penetrating all links in the value chain and how they are connected, have changed the scope of competition and how consumer needs are met (Saniuk et al., 2020 ).

From a sustainability perspective, Industry 4.0 can be defined as a step towards more sustainable industrial value creation, arguing that industrial value creation must be focused on sustainability. In Industry 4.0, there is a lot of focus on sustainability aspects—consumers, business models, economy. By providing detailed information about each point of production, processes, resources, and energy consumption can be optimized across the value network. The new technological solutions promoted by Industry 4.0 are expected to increase production efficiency and the environmental performance of products throughout their life cycle. This also means increasing demand for smart products and smart manufacturing technologies (Stock & Seliger, 2016 ).

The currently observed rapid increase in the implementation of Industry 4.0 technologies and the orientation of enterprises towards the dehumanization of production systems cause many concerns for workers, society, and even governments. In Industry 4.0, the work environment is determined by integrated, advanced and resilient manufacturing technologies, equipped with sensors tracking the work of machines and communication systems enabling data reporting and advanced simulations. The role of current workers is very rarely mentioned. Numerous scientific studies (Romero et al., 2015 ) draw attention to the need to include the crucial role of humans in the assumptions of future industrial development. Above that, it is believed that limiting resilience in technology is not enough. Resilience should encompass the entire value chain, business processes, and even business models. Therefore, in 2019, a discussion began about the concept of Industry 5.0. This concept involves returning the human factor to industry, i.e., increasing cooperation between people and intelligent production systems and combining the best of two worlds—the speed and accuracy guaranteed by automation with humans' cognitive skills and critical thinking (Longo et al., 2020 ).

The concept of Industry 5.0 was considered from 2 to 9 July 2020 amongst participants from research and technology organisations organised by Directorate "Prosperity" of DG Research and Innovation European Commission EC. In the EC document, one can find assumptions to the concept of "Industry 5.0". The essence of this document is critical directions of change to make the industry more sustainable and human-centred (Breque et al., 2021 ).

Industry 5.0 focuses on the interaction between humans and machines (Özdemir & Hekim, 2018 ). Nowadays, humans work alongside machines and are connected to smart factories through intelligent devices (Demir et al., 2019 ). The world of technology, mass customization and advanced production is undergoing a rapid transformation. Robots are becoming even more important as they can now be connected to the human mind via the brain-machine interface and advances in artificial intelligence (Welfare et al., 2019 ). Nowadays, robots are intertwined with the human brain and work as a collaborator, not a competitor (Nahavandi, 2019 ). The fifth industrial revolution will likely push for more advanced human–machine interfaces using artificial intelligence (AI) algorithms. This will mean better integration, enabling faster, better automation combined with the power of human brains (Aslam et al., 2020 ). It also means that robots won't be taking control of manufacturing plants anytime soon, as was so feared in the Industry 4.0 era (Javaid & Haleem, 2020 ). The transition from I 4.0 to I 5.0 means combining the best of the human and machine worlds—it will likely also mean increased productivity (Di Nardo et al., 2020 ; Nelles et al., 2016 ). Vollmer said that Industry 5.0 is the future and emerging trend: interaction and collaboration between man and machine (Longo et al., 2020 ).

In an Accenture survey, as many as 85% of 500 manufacturing company executives said it would be standard for workers and robots to work together "side by side" on production lines as early as 2020 (Østergaard, 2022 ). In the process of human–machine integration, the trend of talent management is accentuated. According to Forbes: 34% of HR leaders invest in workforce learning and retraining as part of their strategy to prepare for the future of work. And 5.0 will free HR teams from much of the day-to-day administration (Eschbach, 2021 ). This will give them time to refine and meet talent requirements, focusing on organizational growth and productivity. Industry 5.0 will bring unprecedented challenges in human–machine interaction (HMI) as it will bring machines very close to everyone's daily lives. It is predicted that Industry 5.0 will create many jobs in HMI and human computational factors (HCF). Industry 5.0 will create new jobs in intelligent systems, AI and robotics, programming, maintenance, training, planning, repurposing, and the invention of a new breed of manufacturing robots (Martynov et al., 2019 ). The goal of Industry 5.0 is a higher standard of living and creativity with high-quality custom-made products to lead to sustainable production and consumption. Many companies in recent years have started sustainable manufacturing programs. In addition, companies continue to implement social responsibility projects. Environmental awareness among people is increasing. Customers are beginning to choose products created by companies participating in the green economy (Elfar et al., 2021 ).

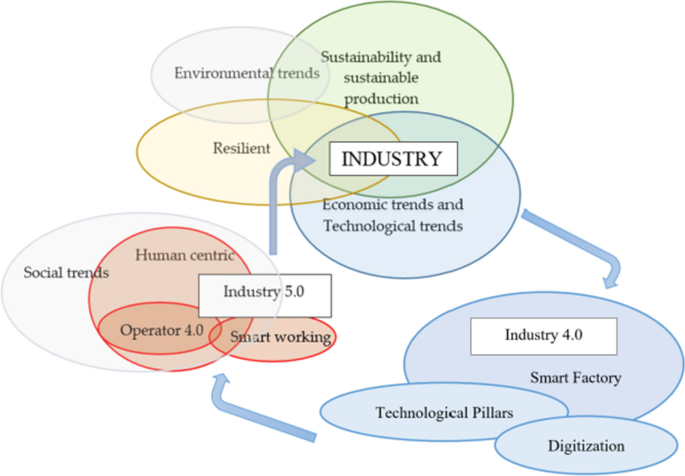

Based on a literature review and a forecast analysis, the essence of Industry 5.0 focuses on three determinants of development: human-centric, sustainable and resilient development (Romero et al., 2016 ; Felsberger & Reiner, 2020 ). The adjective "resilient" has been used by EC. The popularity of the adjective "resilient" is growing. It is considered valuable to describe the features of the Industry 5.0 concept, especially in the effects of the COVID-19 pandemic on economies, societies, and industries. Underlying the development of the new concept are social and environmental needs. Sustainability emphasises that business focused solely on profit is increasingly challenging to sustain in a globalized and highly volatile (unpredictable) environment. For an industry to become a provider of true prosperity, it must include social, environmental and societal aspects. The symbiosis of the three segments: technological, social and ecological constitute the essence of Industry 5.0. Industry 4.0 put technology at the center, while the next one is to be focused on production workers who perceived progressive automation as a threat to their jobs. Industry 5.0 recognizes the power of technology for industrial (business) development but combines the achievement of business goals with social goals in the workplace (e.g., emphasis on workplace safety with the use of next-generation technologies or human–machine relationships) and outside the workplace (social and environmental responsibility) (Gorodetsky et al., 2019 ). The center of the production process is constituted by cyber-physical systems entwined with social and ecological frameworks, the preservation of which (respect, appreciation, compliance) by Industry 4.0 technologies leads to economic growth and places the human being at the center of cooperation. Industry 4.0 is a concept for integrating automation and IT, exchanging data, and creating cyber-physical systems and new ways of manufacturing. It also concerns changes in value chains and the possibilities for personalizing products. All of this is part of the megatrend that is digital transformation. Digitalization has been recognized as the foundation for the development of Industry 4.0 (Kagermann, 2015 ). Industry 4.0 sought a strong collaboration between information and communication technologies (ICT) and operational technologies (OT). The symbiosis of IC and OT technologies was to be achieved in Industry 4.0. Industry 5.0 does not deny the need to digitize societies, economies and industries (Doyle-KEnt & Kopacek, 2019 ).

Digitalization in Industry 5.0 should be comprehensive to organize processes in the enterprise and supply chains. Industry 5.0 emerged from the megatrend that is Industry 4.0. The emerging picture of the Industry 5.0 paradigm is the penetration of artificial intelligence into people's daily lives. There are voices among researchers that probably a more precise term instead of Industry 5.0 is "Society 5.0" (Super Smart Society) (Elim & Zhai, 2020 ). Unlike the concept of Industry 4.0, Society 5.0 is not limited to the manufacturing sector but solves social problems through the integration of physical and virtual space. Society 5.0 is a society in which advanced technologies are actively used in people's lives, in industry, health care and other spheres not for the sake of progress but the benefit and convenience of every person (John et al., 2020 ).

Materials and methods

The bibliometric analysis methodology was used, which is the most suitable for studying the evolution of areas of scientific research conducted in the field of transformation of the Industry 4.0 concept into the Industry 5.0 concept. As one of the quantitative methods, the bibliometric analysis allowed determining the state and development trends of the literature in the subject of the evolution of the Industry 4.0 to Industry 5.0 concept. In the analysis, the authors focused on the number of publications in segments according to characteristics (research criteria): citation rates, types of publications, research areas as units of measurement. The analysis results were presented in the forms: figures, tables and descriptions. Furthermore, the bibliometric analysis has made it possible to identify the internal logic of the evolution of Industry 4.0 to Industry 5.0. The advantage of the bibliometric measurement carried out is its objectivity. In the article, the Systematic Literature Network Analysis (SLNA), introduced by Colicchia and Strozzi ( 2012 ), was adopted as the bibliometric analysis method. This analysis combines a systematic literature review (SLR) and analysis with the visualization of the bibliographic network. This approach identifies critical trends and issues that influence knowledge development in a given field more scientifically and objectively than descriptive reviews.

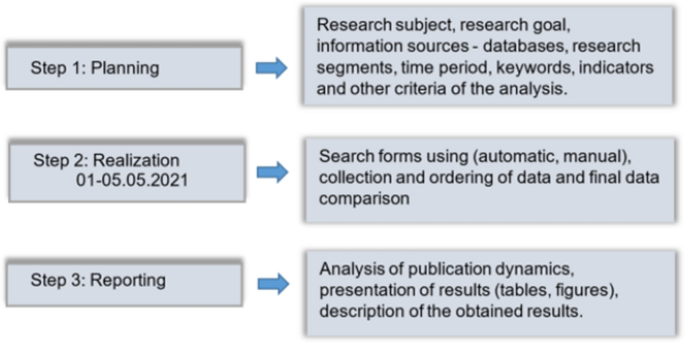

In the methodology of the bibliometric analysis adopted in the study, the following stages were carried out: planning, implementation, reporting. The methodology of the bibliometric analysis is presented in the Fig. 1 .

Methodology of the conducted bibliometric analysis

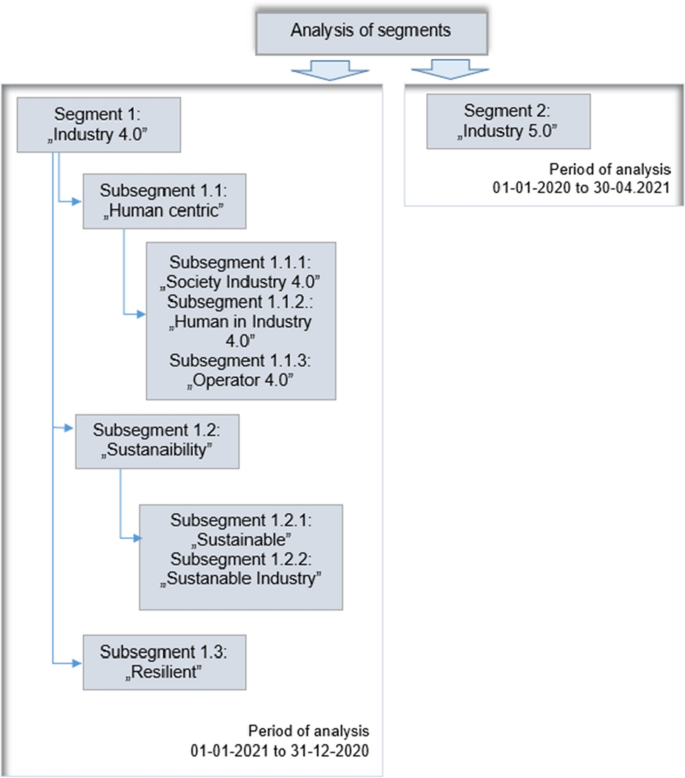

The search for scientific publications was carried out using the Core collection Web of Science (WoS), a database provided by Clarivate Analytics, on 01–05 May 2021. The phrases used to search the database were organized into segments, and topics and research periods contained the mentioned phrases. The selection of phrases was based on available studies about Industry 5.0 (and presented in the literature section of this publication). The following two main segments of the bibliometric analysis were determined:

Segment 1: „Industry 4.0” (8085 publications).

Segment 2: „Industry 5.0” (22 publications).

Research segments and analysis period in the area: Evolution of Industry 4.0 to Industry 5.0

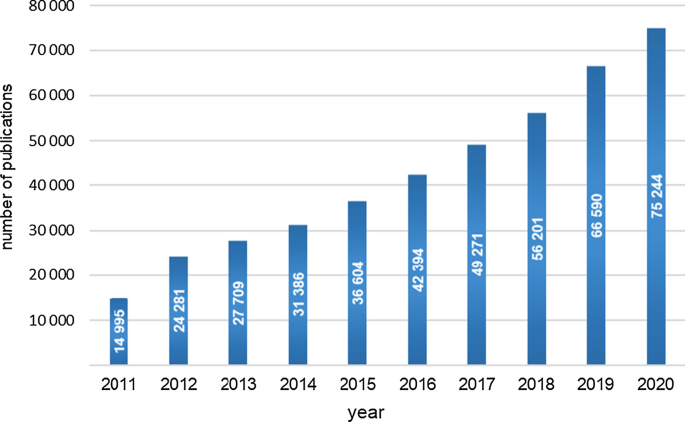

Industry 4.0 annual publications

Areas of interest for Industry 4.0 researchers

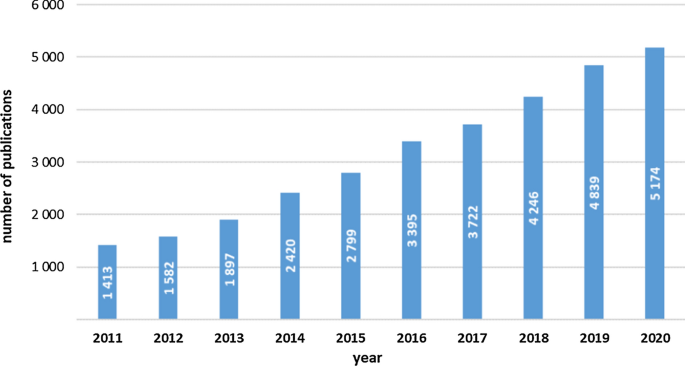

Industry 5.0 annual publications

Map of key words used in publications about Industry 5.0

Distinct segments of Industry 5.0

Progress in the research field: “Human centric”

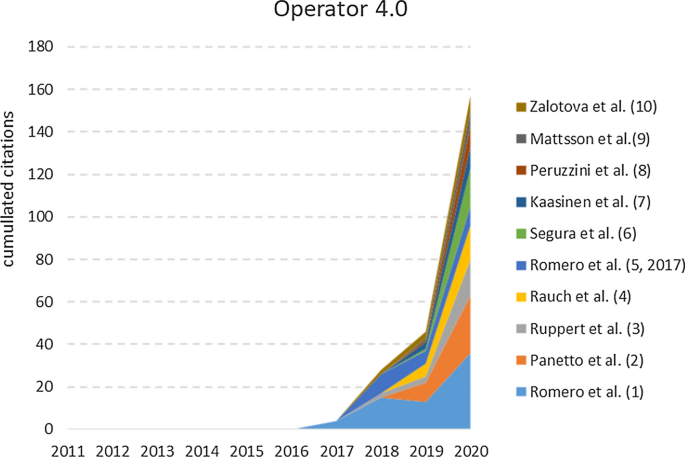

Cumulative results of analysis of research field: Operator 4.0

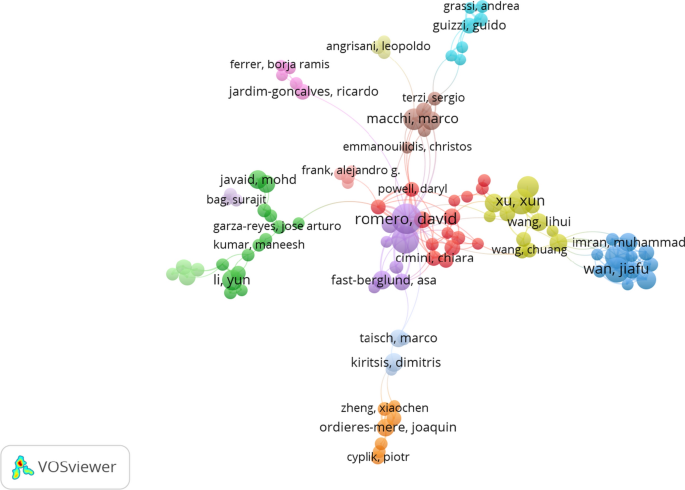

Semantic map showing the citation network of author Romero David

Progress in the research fields: Sustainability with sustainable

Progress in the research field: “Resilient”

Results of bibliometric analysis in the new research field: “Industry 5.0”

Results of bibliometric analysis in the new research field: “Industry 5.0” (human factor)

Results of bibliometric analysis in the new research field: “Industry 5.0” (Operator 4.0)

The segments: "Industry 4.0" and "Industry 5.0" were crucial to realize the research area: Evolution of Industry 4.0 to Industry 5.0. In addition to the key segments, the content of scientific publications in the sub-segments of industrialization was analyzed (according to the EU document):

Sub-segment: "Human-centric" (36 publications) and related: Society Industry 4.0 (418 publications), Human in Industry 4.0 (1193 publications), Operator 4.0 (1040); these areas are a reference to the humanization of industries;

Sub-segment: "Sustainability" and its related meanings such as Sustainable, Sustainable Industry 4.0; these areas represent the essence of the development of industries (as conceptualized by the policies of each country) (1286 publications);

Sub-segment: "Resilient", which is highlighted in the EC (Research and Innovation) document as flexible and adaptable technologies in Industry 5.0 (78 publications).

These sub-segments complement the research area: Evolution of Industry 4.0 to Industry 5.0 and provided phrases to complete the bibliometric analysis for segments 1 and 2. The following periods of bibliometric analysis were established for each key segment:

From 01-01-2011 to 31-12-2020 for the segment: Industry 4.0". The analysis began in 2011, as this is when the name "Industry 4.0" was first used in Germany;

From 01-01-2020 to 30-04-2021 for the segment: "Industry 5.0". The analysis began in 2020 when the name "Industry 5.0" was first used by the European Commission.

The designated time frame is a closed period, which made it easier for the authors to make comparisons of segment sizes (number of publications).

The procedure for bibliometric analysis was as follows: Selected database: Web of Science (Core Collection);

Basic search: Topic (title, abstract, keywords author; Keywords Plus);

Data collection: 01/05-05-2021;

Timespan: used periods: from 01-01-2011 to 31-12-2020 (for “Industry 4.0”) and 01-01-2020 to 30-04-2021 (for “Industry 5.0”);

Result limitation: English language;

Used: Vosviewer, Excel, content analysis of selected works, keyword grouping (Fig. 6 ), Venn diagrams which were used to present the configuration of the segments (research fields) obtained from the bibliometric analysis). The size of the boxes reflects the strength of the researchers' interest in the given subject area. In addition, the arrangement of the fields is logical—the top fields are above the keywords, the subordinate fields are below (Figs. 13 , 14 , 15 , 16 );

Results: number of publications, publication years, citation, document types, research areas.

Figure 2 shows the analyzed segments (research fields/nomenclature used interchangeably in the publication: segment or research field) along with the established analysis periods.

Web of Science is an interdisciplinary (multidisciplinary) research platform that captures the content of over 12,000 high-profile journals and over 160,000 conferences from around the world. It allows researchers to search multiple databases simultaneously from a single interface—via the Web of Science ™ Core Collection. This database collects many bibliometric indicators and includes literature from most disciplines. It covers many other databases and tools necessary to establish bibliometric indicators, parametric evaluation and creating a bibliography. It is also the most widely used database and citation database for research purposes. Its decisive advantage is its transparency and order. The Web of Science database is one of the most consistent databases of scientific publications. Compared to e.g. the Scopus database, Web of Science has a search ability “shorter range of year”. Considered area of research and high dynamics of changes has a significant impact on the analysis results. However, a severe disadvantage of the Scopus database is the quality of the data, which is not "clean" like that of WoS, as some publications are not identified (Zhao & Strotmann, 2015 ). Therefore, the authors decided to use the WoS database.

Results and discussion

According to the methodology adopted, the research results and discussion will be presented according to the following order: first, general data on the number of publications in the field of Industry 4.0 and Industry 5.0 will be presented, followed by results on Industry 4.0 (in particular human-centric, sustainability and resilience), and finally results from the field of Industry 5.0.

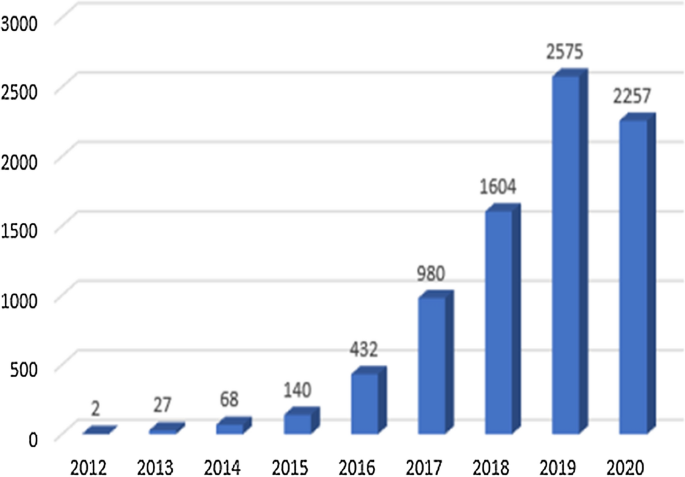

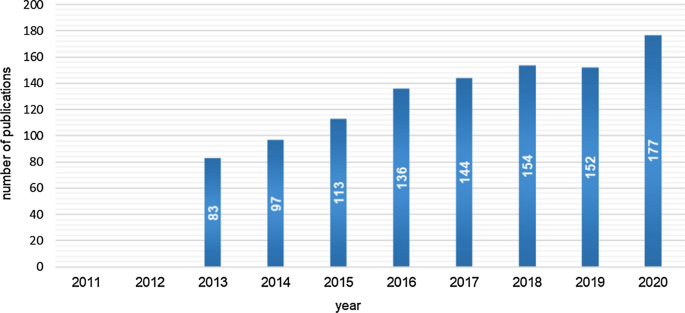

Figure 3 shows the number of publications for Industry 4.0 by year. As shown in the figure, the trend of publications for "Industry 4.0" was upward until 2019. In 2019, there were 2573 more publications for Industry 4.0 than in 2012 (only two publications were reported then). The first two publications in the database were by Bettenhausen ( 2012 ), Hofmann et al. ( 2011 ). The first publication referred to ICT trends that preceded the development of the Industry 4.0 concept, the second to the use of mobile devices in Industry 4.0. There was a decrease in the number of publications in 2020 compared to the previous year (318 fewer publications). Academic interest in Industry 4.0 topics will peak in 2019.

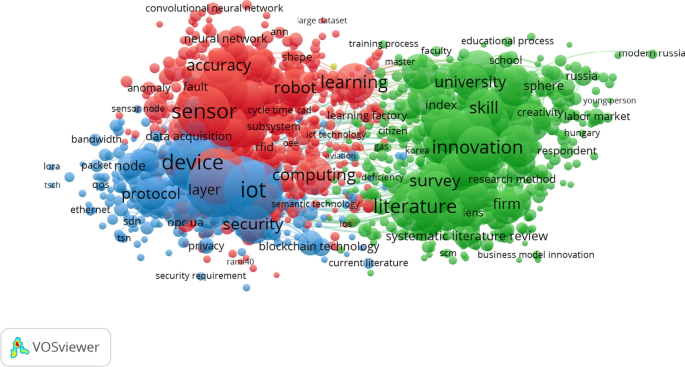

Based on the retrieved articles, a semantic map was created that shows the areas of interest for Industry 4.0 researchers (Fig. 4 ). Verification of the term network shown in Fig. 4 reveals potential relationships grouped into themes. For publications identified in the "Industry 4.0" area, the terms fall into three clusters, whereas many as two of them are oriented around technology. It is difficult to find themes related to "human", "Sustainability", or "resilient". The red cluster is oriented around sensing and includes the robot, learning, accuracy, neural network and shape. The device consists of, e.g., IoT, security, protocol, layer, the node in the blue cluster. The third cluster, green, includes concepts related to innovation (literature, university, school, firm, business model.

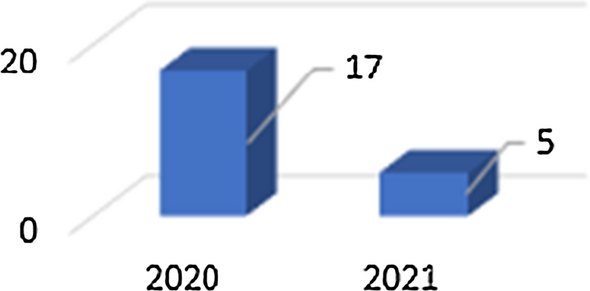

In 2020, the first publications on Industry 5.0 appeared (Fig. 5 ). At the end of April 2021, the number of articles containing "Industry 5.0" was 22. There were 17 publications in 2020 and 5 in 2021 (between January and April).

Table 1 summarizes the results of the research area analysis: Industry 5.0 in the database: WoS. During the study period, 22 papers were found (17 papers from 2020 and 5 papers from 2021); 14 of them were available in open access. The total citations of these papers were 53, the Average Citations per Item was 2.41, and the h-index was 5. Most papers were classified as articles (18), 3 papers were early access, 3 proceedings paper, and one editorial material. All papers are written in English. Most papers (6) are from the US, Italy (5) and China (2). The papers were indexed in the following research areas: Engineering (7), Business economics (6), Computer Science (6), Chemistry (3), Materials Science (3), Environmental Sciences Ecology (2), Science technology other topics (2), Instrumentation instruments (1), Metallurgy, metallurgical engineering (1), Physics (1), Social sciences other topics (1), Telecommunication (1).

Table 2 summarizes the results of the research field analysis: Industry 5.0 with the highest number of citations. The ten papers with the highest number of citations are outlined in the table. Next to each paper, the total number of citations, the average number of citations per year, number of citations in 2020 and 2021 were marked. The publication of Bednar and Welch (11) received the most citations. The topic of the publication was sociotechnical determinants of smart work. The authors of this work used the following keywords: smart working, social-technical approaches, open system, emergence, Industry 4.0 and Industry 5.0. The essence of the publication is "smart working", according to the assumptions of Industry 5.0, in which technological and social systems work in harmony, and a person is an active participant in cyber-physical systems. Analyzing the number of citations of the works collected in the table, it can be noted that Industry 5.0 is a young concept, which is still relatively unknown among researchers.

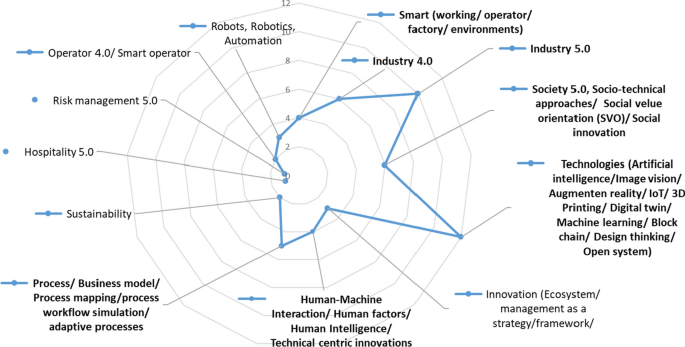

The research areas Industry 5.0 were analysed in terms of keywords of individual articles (Fig. 6 ). The result is a map of keywords developed based on open access publications—14 publications listed in the WoS database were used, indexed during the data collection period 01-05-05-2021. The identified keywords were combined into groups for increased readability. Based on their experience, the authors intuitively combined the keywords reported in the authors' publications into aggregated groups representing individual keywords.

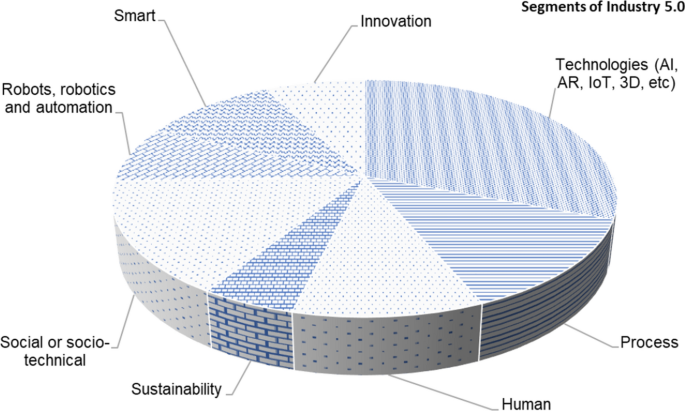

Based on content analysis of publications in area of Industry 5.0, it has been established that the socio-technical and human segments are among the segments relevant to this concept. The segments were developed based on the subject area indicated by the publication's authors in their methodology. A detailed analysis is shown in Fig. 7 . Scientists (researchers) have emphasized the phenomenon of 'smart'. Some pointed to the fourth industrial revolution (Industry 4.0), in which 'smart factories' use robotics to achieve high productivity. Others saw progress toward Industry 5.0, in which technological and social systems work in harmony to deliver personalized products to the masses. Keywords connected with segments: 'innovation', 'technologies' and 'process' also fit into the framework of the new concept. The process approach has been a determinant of how companies operate in the marketplace for many years. Industry 4.0 technologies are also used to develop Industry 5.0. They are still focused on process optimization and innovation, assuming that socio-technical conditions are the best way to support smart technologies in companies (Bednar & Welch, 2020 ).

The stage of the analysis was the "human" segment. Within this segment, 1,182 publications were recorded (Fig. 8 ). More than 100 publications per year were recorded starting in 2015. In the first two years after the emergence of the Industry 4.0 concept, there weren't publications in the database using the "human-centric" keywords. Due to the small number of publications, this segment was classified (at the current stage of development) as niche but pretending to be a key area of research.

In the research field: "Human-centric" several subsegments can be distinguished, and so: "Society Industry" was formed by 5 publications, "Human in Industry 4.0" was built by 2 publications and "Operator 4.0" had as many as 35 publications with the sum of the times cited: 367 and average citations 10.49 by h-index: 11). The highest citation index was obtained by Romero et al. ( 2016 ) (presented in the first row in Table 3 ).

The progress of the analysis for “Operator 4.0” using cumulative values based on selected articles is shown in Fig. 9 .

Based on analysis, citation accrual of the publication Romero et al. ( 2016 ) by other authors was found (Fig. 10 ). From the publication (Romero et al. 2016 ), the citation links of this publication by other authors (total 78 publications in the WoS database) were established. Author Romero David's citation map gives an overview of the structure of interest in "Operator 4.0" regarding the number of citations. On the map, you can identify clusters of related authors citing works from the area of "Operator 4.0". Each cluster is characterized by a different color and contains a network of links between the authors who mention the author with the most citation. This author is marked on the map in the bigger font (quoted at least five times). The circle size indicates the number of citations of a given author. The author Romero David received the most citations. The number of authors' collaborations means 11 separate clusters following David Romero.

Repeated keywords that belonged to the "Human-centric" segment were analyzed. In the research area: "Human-centric" includes a broad new topic: "Operator 4.0". The list of analyzed keywords is presented in Table 4 . The authors listed all keywords in the research field: "Human-centric" by using keywords in particular publications. The analysis results will be used to develop sets of studies presented using Venn diagrams (later in the article).

The next level (field) of analysis was "Sustainability". The list of analyzed publications from the research area we considered niche and named: "Sustainable Industry 4.0" is summarized in Table 5 . In both Industry 3.0 and Industry 4.0, sustainability was the paradigm of business management. In the new (next) development concept—Industry 5.0—sustainability remains the strategic direction of the business. The analyzed area "Sustainability" was enriched (expanded) with the adjective "sustainable". The adjective "sustainable" was found in publications more often than the noun "sustainability". Indications increase for both "Sustainability" and "Sustainable". The results of the searched publications are presented in Fig. 11 . The adjective "sustainable" is combined with the words: production and manufacturing, product, process, development, economy, and Industry 4.0. Additionally, the sub-segment "Sustainable Industry 4.0" was introduced into the analysis, which we classified as niche because the number of publications was low (only 9 publications, including 2 in 2018 and 7 in 2020).

The last area (field) analyzed was "Resilient". The results found are presented in Fig. 11 . In 2020 there were 5174 publications in the WOS database using the search phrase "Resilient". This resulted in an increase of 3761 publications in the year under review compared to the number of publications in 2011. "Resilient" means resilience, resilience, flexibility. The adjective describes many aspects of business, enterprises, and most importantly, equipment, machinery and technology. Based on the number of results obtained, it was classified as a significant area (field) of research in the era of industrialization. Every two years, one can notice a significant increase in publications with the adjective "resilient" in the subject or keywords. Concerning Industry 5.0, the adjective "resilient" has been used by EC (cited document from January 2021 several times already). The popularity of the adjective "resilient" is growing. It is considered valuable to describe the features of the new concept of industrial development Industry 5.0 especially in the context of the effects of the COVID-19 pandemic for economies, societies and industries (Fig. 12 ).