Retail | How To

How to Organize Inventory for Small Businesses in 9 Steps

Published August 3, 2023

Published Aug 3, 2023

REVIEWED BY: Meaghan Brophy

WRITTEN BY: Brigitte Korte

Download our free workbook

Your Privacy is important to us.

This article is part of a larger series on Retail Management .

Need help with inventory?

Step 1: Choose an Inventory Management Method

- Step 2: Organize Product & Vendor Information

- Step 3: Create & Submit Accurate Purchase Orders

Step 4: Receive Orders Accurately

- Step 5: Tag & Label Inventory

Step 6: Organize Your Stockroom or Warehouse

Step 7: track inventory in real time, step 8: conduct regular inventory counts, step 9: reconcile discrepancies, bottom line.

Inventory management is the process of having the right products, in the right quantities, at the right time to sell to customers. Accurately managing inventory can increase revenue by preventing stockouts, excess inventory, and unsold products.

While I have seen it done manually, the easier and more reliable solution for managing inventory is to use a software program that automates your inventory management processes. Our recommended solution for inventory management for small businesses is Lightspeed, as it combines both the POS system and inventory management suite to streamline your operations.

Visit Lightspeed

If you’d rather manage inventory manually, download our free inventory management workbook:

FILE TO DOWNLOAD OR INTEGRATE

Inventory Management Workbook

Thank you for downloading!

Lightspeed offers the best inventory management system for small businesses.

Before you begin working with your stock, you need to choose an inventory management method. As I mentioned earlier, the methods you choose should be ones that best allow you to maintain the right products, in the right quantities, at the right time to sell to your customers.

In my experience, combining a few different inventory management methods is the best way to successfully manage inventory.

The inventory management method (or methods) that makes sense for your business will depend on a few factors, including:

- Product quantity

- Product value

- Cost of goods sold (COGS)

- Turnover ratio

- Product type (perishable vs non-perishable)

- Product size/weight

- Product quantities

- Product variations

- Turnover rate

- Carrying costs

Once you have chosen your inventory management methods, you can implement them by programming an ordering cadence, automations, and alerts on your inventory management software or point-of-sale (POS) system . Or, if you are managing your inventory manually, you will need to monitor your books and item quantities to ensure implementation.

Below, you can click through a few of my most recommended inventory management methods.

First-in, first-out inventory management , also known as FIFO, is one method to assign costs to ending inventory. FIFO assumes that the first items that are purchased will be sold first to assign a cost to the inventory remaining at the end of the year.

The last-in, first-out inventory method , or LIFO, assumes the most recently purchased inventory (“last in”) as the cost of goods sold (COGS). In other words, recently purchased goods are expected to be expensed first or transferred to the COGS.

This method is popular in the US because it’s allowed for tax purposes, and many proponents believe it most closely matches the replacement cost of inventory.

Average Cost

The average cost method , or AVCO, is another method used to determine the cost of inventory at the end of the year and the COGS during the year. Under AVCO, the cost of inventory is based on the weighted average cost of inventory purchases during the year. Because it uses an average cost of goods in inventory rather than tracking individual units, it is typically simpler to use than FIFO or LIFO.

A perpetual inventory system calculates your COGS after each sale, as opposed to periodically. This is also called live sales tracking in a POS system and simply means that your inventory information will update as transactions happen. You will also want to be sure that this includes all your sales channels, including online and additional locations.

A periodic inventory system calculates your COGS periodically when you perform physical inventory counts. This is a more common practice for businesses managing their inventory manually but is also used less frequently in conjunction with automated perpetual inventory management systems.

Specific Identification

The specific identification inventory method identifies each individual unit of inventory and assigns its actual cost. This inventory management method doesn’t use assumptions like the FIFO, LIFO, or AVCO methods. The COGS and ending inventory are determined by the actual cost assigned to each physical unit of inventory and what is actually sold and unsold.

Step 2: Organize Product & Vendor Information

The first step in organizing your inventory is to set up your stock and supplier information in a reliable and accessible system. Some businesses will use manual tracking methods such as spreadsheets to keep track of their products and vendors.

However, as was the case at my store, the best option for retailers is to use a POS system that will keep searchable vendor and product directories.

There are lots of POS systems to choose from, and they all have unique inventory systems. Read our guide to learn more about the best POS inventory systems for your business.

- Product Information

- Vendor Information

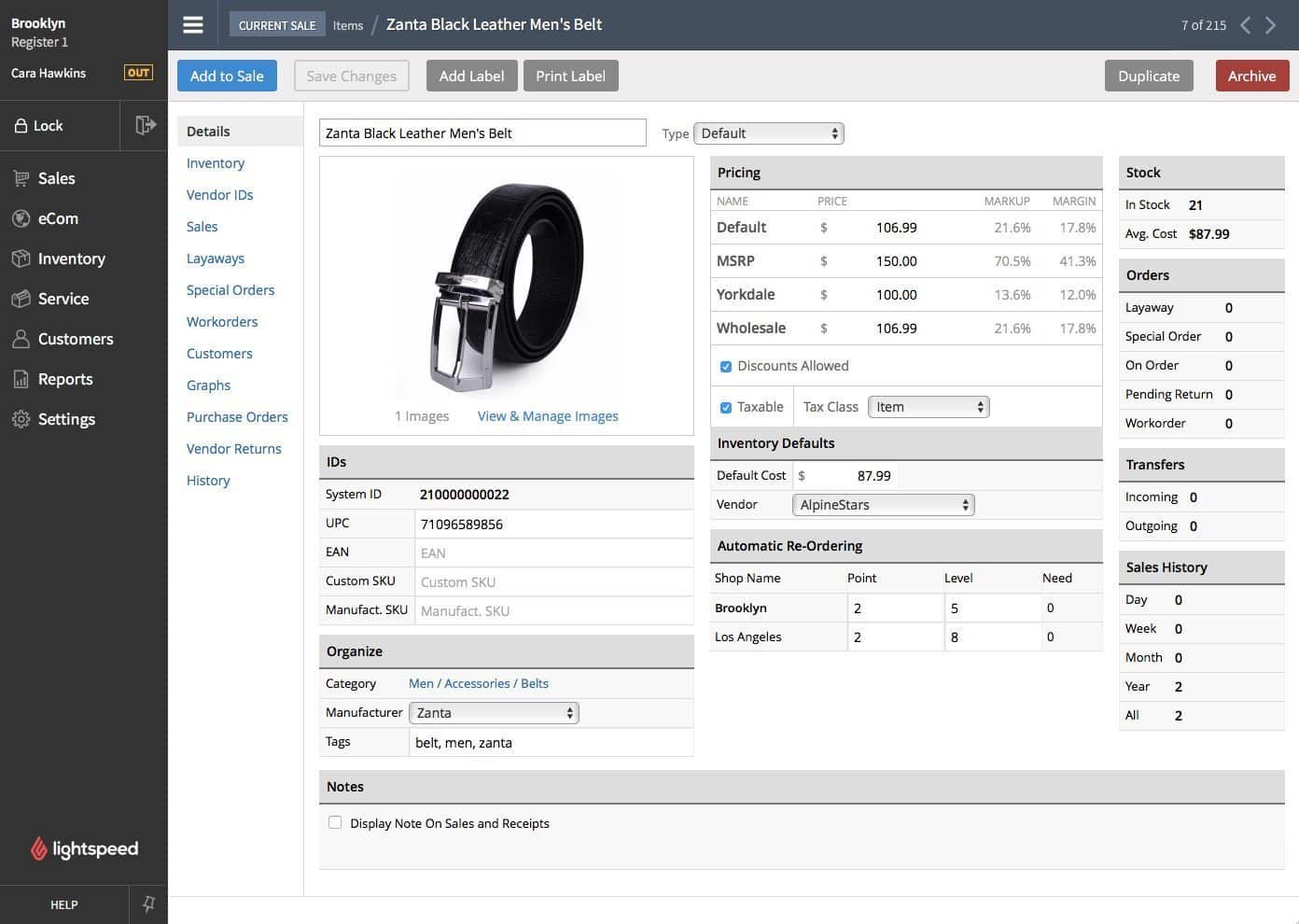

To organize your products, you’ll first need to record information about each item and file it on a product page. Product-specific information should include:

- Product name

- Your internal product stock-keeping unit (SKU) number

- Manufacturer’s Universal Product Code (UPC)/European Article Number (EAN) or other unique identifiers

- Short description

- Product category, class, or family

- Wholesale cost

- Regular retail price/MSRP

- Your selling price

- Colors or sizes

- Vendor, supplier, or manufacturer name

- Reorder quantities

- Shipping details: size, weight, box pack, cost, dispatch time, etc.

- Picture or product image

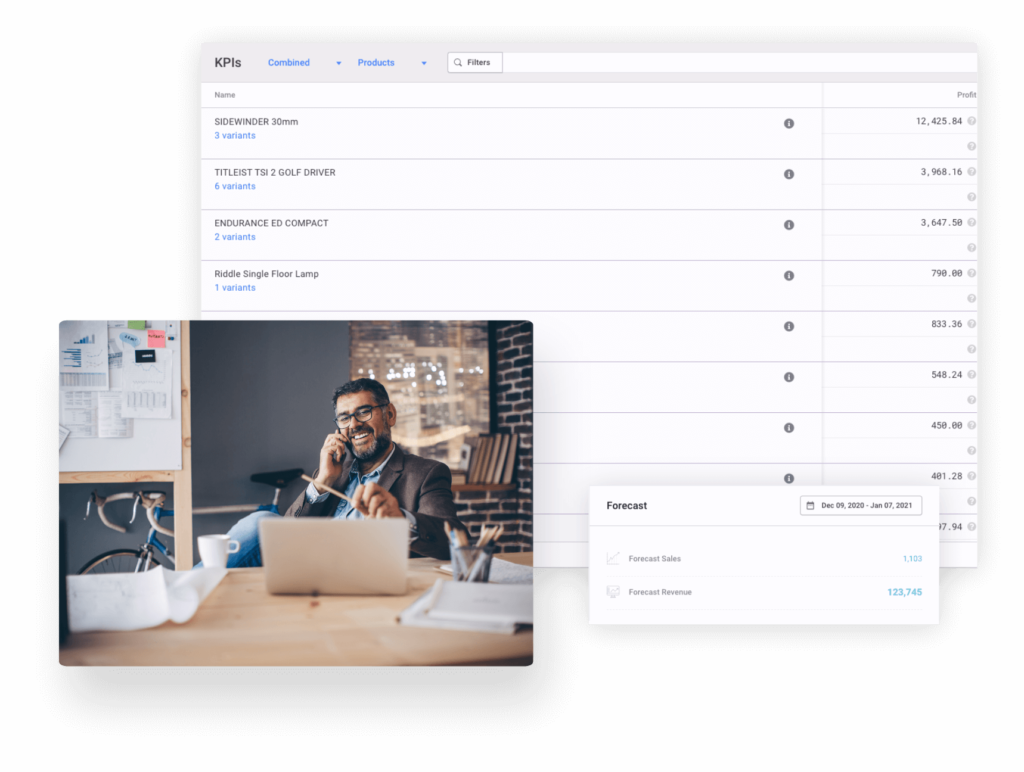

Keep track of your product information so you can reference it over time and reorder easily. (Source: Lightspeed)

In addition to creating a log of your products and their information, you will need to file your vendors’ information into your inventory system. That information should include:

- Vendor name

- Vendor contact name

- Vendor billing information

- Vendor phone

- Vendor email

- Vendor website

- Order volume

- Payment terms

- Line rep or showroom contact

- Fulfillment and shipping times

- Top products from vendor

Not ready to invest in a POS system with inventory management capabilities? No worries. There are also several free inventory management software available.

Expert Tip: Build Relationships With Product Suppliers

Even with the best inventory management plan, issues can still arise where you need products ASAP to fulfill an order. When this happens, retailers are at the mercy of their suppliers. If there is a quality control issue or a discrepancy with a purchase order, having a good relationship with your supplier can help resolve these issues quickly.

I was able to build strong relationships with product suppliers by sticking with the same suppliers when I could, meeting suppliers in person at trade shows, and, perhaps most importantly, paying invoices on time.

As sustainability is becoming more critical to consumers and they demand greater environmental efforts from businesses, 53% of businesses are increasing their focus on sustainable sourcing .

Step 3: Create & Submit Accurate Purchase Orders

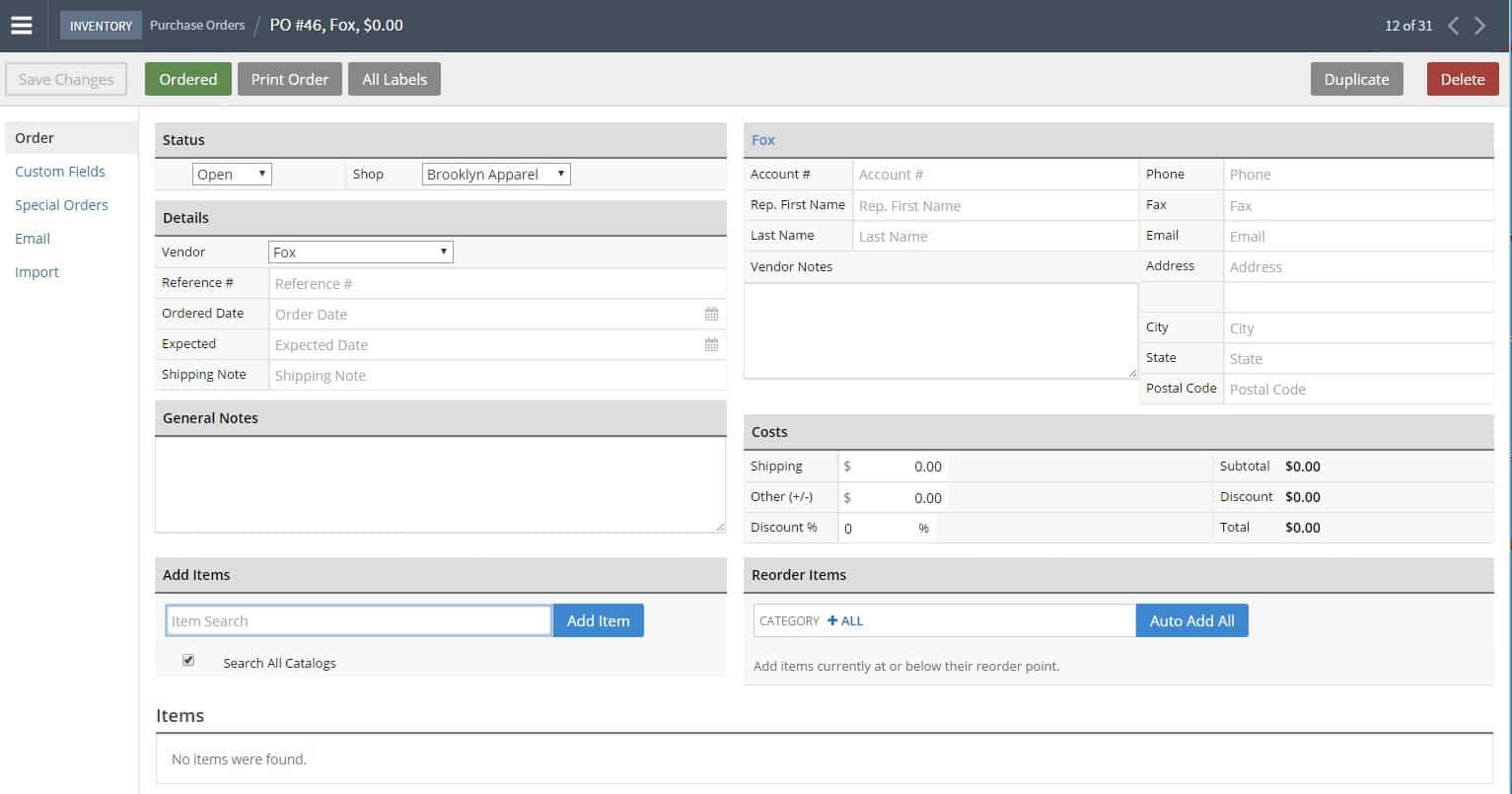

A purchase order (PO) is a buyer-created record of an order that is submitted to the vendor and serves as a legal contract for the sale of goods. You use POs to cross-reference actual goods and invoices received to those ordered and paid for. If there is a discrepancy between your PO and the goods received, you can use your PO to return to the vendor and settle up.

Purchase orders record what you ordered from your vendors and act as a receipt that you can compare to the goods you actually receive.

I submitted my POs to vendors electronically through email or the vendor’s online ordering portal, as is preferred over any paper system. While I didn’t use one at my store, some POS systems, like Lightspeed, have PO features that let you create and manage POs right from your POS system. Some systems even include vendor directories to manage vendor contact information, automated PO creation at set stock points, and receiving tools with POS data built in.

In the news:

As the economy continues to dip and consumer habits become more conservative, the inventory-to-sales ratio is rising, hitting 1.29 in April 2023 , with an upward trajectory. This means that for every sale, retailers have an average of 1.29 pieces of inventory. To account for this new economic environment, retailers should slow their purchasing rates to match slowing sales rates.

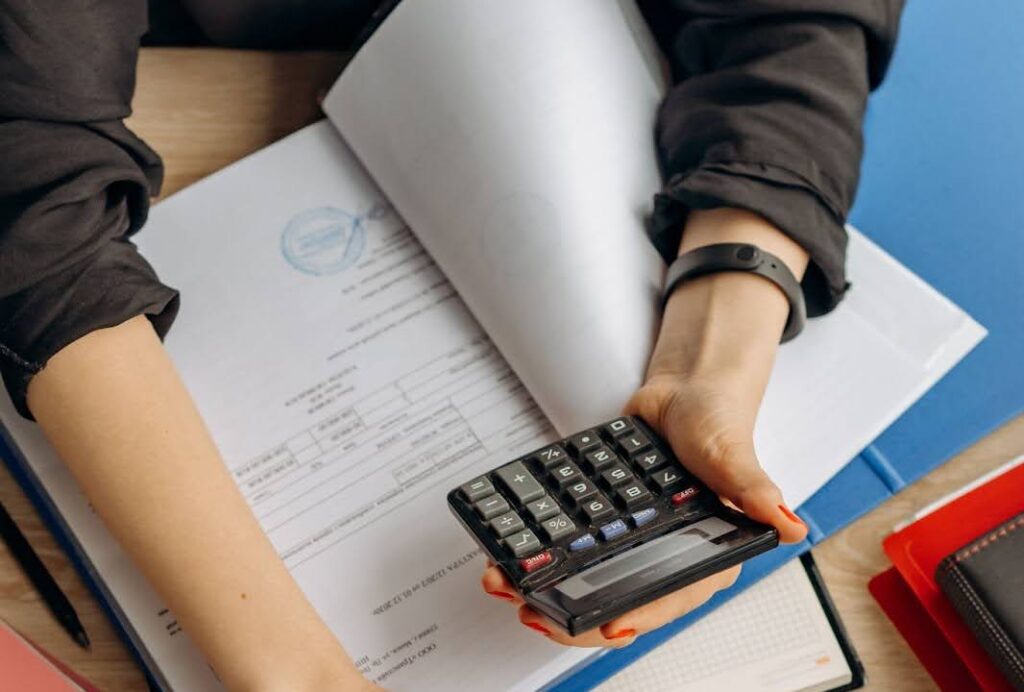

Once you have submitted your purchase orders and your suppliers have fulfilled them, you want to be sure that you receive your stock accurately. Supplier error is fairly common, and if you aren’t being systematic about receiving your inventory, you might get shorted, overcount, or underestimate your inventory levels—which can lead to shrinkage (having less product than your records show) and a decrease in your margins.

To ensure the accuracy of my orders, I followed these steps:

- Unpack the shipment and organize items by product.

- Count/scan products.

- Compare the count to your PO.

- If the counts and products match, file as received.

- If you find errors like wrong, shorted, or missing items, note these on your PO and contact your supplier immediately to resolve them.

- Shelve or store all correctly received stock (tag or label first if needed for your system).

- Enter your invoice into your accounting system.

The inventory management system that I used had an accompanying app that turned my phone into a barcode scanner. I could then select “receiving” as the task and scan products, and the app would count and log my shipments for me. This made my life so much easier, so I would suggest looking for a barcode scanning app as a POS feature.

Accurately counting and receiving stock is important for preventing shrinkage and ensuring the accuracy of your orders. (Source: Pinterest)

Did you know?

According to a widely reported stat, only 6% of companies report full visibility into their supply chain.

Step 5: Tag & Label Inventory

Once your products are physically on hand and accounted for, you will need to tag and label them so they are ready for the sales floor and organized internally.

To ensure your tags are ready for both the sales floor and the stockroom, they should include these main things:

- Price: The selling price of your item. All your inventory will need this before it can go out on the floor and be customer-facing.

- Product Labels: You should have some sort of labeling system for your inventory so you can easily organize and track it internally. We recommend using both a barcode label —so you can easily scan items in your inventory system and at checkout—and a descriptive written label, like “red shirt” or “child’s leggings,” that corresponds with where the item goes in your store and in storage.

Learn about the different types of labels you can use for your products to keep them identifiable and organized with our guide to UPCs and SKU numbers .

Regardless of the type of labels you use, a good time to tag and label inventory is during the stock receipt process. This ensures the task isn’t overlooked and prevents the unlabeled stock from being shelved or displayed for sale.

Once printed, labels should be fixed directly to the product. Some inventory might even arrive prelabeled with the manufacturer’s barcodes, description, and price. If you aren’t using an internal labeling system, this makes your job easy. You can just start organizing.

Use our guide on how to create barcodes (plus a barcode generator) and check out our picks for the best barcode label printers to get started labeling your products.

Having an organized stockroom will not only make things easier to find but will allow you to fit more merchandise and keep better tabs on your inventory. I remember taking the first week at my store to completely reorganize the stockroom to improve its functionality and make my life 10 times easier.

In retail stores, tall storage shelves or double-tier hanging racks can maximize your wall space while allowing movement and easy access. Additionally, storage bins can be stacked and labeled on the ground to use floor space efficiently.

In larger warehouse settings, there is typically more room to store goods within aisles that have built-in shelving and hanging storage. The biggest thing you will want to ensure is that you choose storage devices that make sense for your merchandise and can change over time.

For example, my store had a very small storage room, so we used lots of hanging racks and stacked bins to maximize the little space we had. The racks were easy to roll, and we could label them any way we needed with rack tags. Similarly, the bins were great for our heavier/knitted items that took up too much hanging space or couldn’t be hung, and were easy to label, depending on the inventory we had on hand.

Whatever your method, your stored inventory needs to be well-organized, clearly labeled, and accessible for pulling and inventory counts. This can be done using the boxes goods come in, stacking bins, or even hanging separators for hung apparel.

Utilize your wall space to fit as much product as possible in limited space. (Source: Pinterest)

Do you use a warehouse to store your products? Learn how to keep your warehouse operation efficient with our guide to warehouse layout design planning .

Tracking your inventory levels in real time is key for keeping the right items on the shelves in the right quantities—i.e., good inventory management. Whether by hand or through your POS system, a sound inventory management system records every sale in detail and adjusts inventory levels as each item is sold.

There are some great inventory management software that you can use to get real-time updates and stay on top of your inventory. Learn more about the top products on the market with our guide to the best inventory management software .

While you can use a spreadsheet for inventory tracking, I used a POS system with integrated inventory management. My POS system tracked inventory levels in real time and adjusted quantities with every sale. Then, as my inventory numbers would dip below my designated safety stock level , I would get automatic low-stock alerts and PO generation for the low-stock items.

A POS system will make tracking inventory levels and reordering your supplies quick and easy and, most importantly, will base your inventory levels on actual sales, not on your best guess.

I used to believe that inventory counts were unnecessary if you had a POS system keeping tabs on your inventory levels. Physical inventory counts can be mundane and tedious, so why not defer to technology?

The answer: Technology isn’t always 100% accurate, and it can’t account for products lost to shrinkage. Getting into your stock room and actually counting your products is the only way to know exactly what you have, allowing you to settle disparities between actual levels and those on your POS and manage your stock accurately.

Most small businesses do a full inventory count once each year for tax purposes but will also perform smaller partial inventory counts, or cycle counts, throughout the year.

Here are the types of counts you should perform to ensure you have an accurate eye on your inventory:

Quantity on Hand

The basis of both annual and cycle inventory counts is your current Quantity on Hand (QOH) or the amount of inventory you should have in stock for every item you carry. The formula for QOH is as follows:

QOH = (Previous QOH + Received Inventory)-Sold Inventory

Your QOH is the number you will measure your annual and cycle counts against. So, for example, if I thought I should have 272 packs of gum based on my QOH calculation, I would be looking for 272 packs of gum in my cycle or annual count. If I found a discrepancy, say only 250 packs of gum, that would indicate an error or theft that I could then look into further.

Annual Inventory Counts

Annual inventory counts are a complete inventory count, typically done at the close of each fiscal year for income tax purposes. These counts give you an overall picture of how much inventory you have on hand at the close of your year. They can also help businesses uncover inventory shortages due to miscounts, shrinkage issues, misplaced stock, and/or receiving errors.

While most retailers perform more frequent counts, some small businesses with limited staff or small inventories will only perform this type of inventory count each year. While annual inventory counts are a good practice regardless, by year’s end, it’s too late to fix most of the problems they reveal. To catch inventory issues before they become costly, you’ll also want to conduct periodic counts, called cycle counts.

Regular counts will also help you understand what stock is not moving and might need to go on sale to avoid incurring greater carrying costs (the expenses a small business must pay to hold and store unsold merchandise).

Cycle Counts

Cycle counts are periodic spot counts that take inventory of specific categories or subsets of products. For example, at my boutique, we would do a couple of cycle counts each week for different types of clothing—basics T-shirts one day, jeans another, earrings the next. Cycle counts helped us see how specific products were performing and determine whether it was time for a restock.

Typically, you perform cycle counts on a regular basis. So, you might decide to count shirts every other Wednesday and jeans every two months. As a best practice, you would cycle count all of your products daily to keep a good grasp on their levels. Without the right tech and staff, however, this is next to impossible. Schedule your cycle counts based on the speed with which you move through your inventory, with items that sell faster getting more frequent counts.

Manual vs Automated Counting

When it comes to how you count your inventory, you have two options. You can either do it manually or use a POS system to automate your processes. Here, we will look at both:

- Manual Counting

- Automated POS Counting

While we would suggest using a POS system to count your inventory for you, if you do decide to go the manual route, your first step will be tallying your QOH based on your POs, last year’s inventory, and a sales tally of each item sold. From there, you’ll need to create inventory count sheets to record your physical counts and begin counting.

Manual counts are less accurate and more time-consuming than your automated POS option.

While a POS system can’t count all the physical items in your inventory, it can place live QOH counts and inventory lists at the tips of your fingers to help accelerate and streamline your inventory counts. We suggest a POS system to help eliminate errors in your inventory management and make your business more efficient.

If you do decide to go with a POS system to count and track your inventory, we recommend Lightspeed. It keeps live QOH counts as you receive and sell items, continuously tracks your inventory levels, alerts you to low-stock items, and provides reports and data to help you better understand and manage your inventory.

Ideally, your physical inventory counts will match your projected quantities on hand (QOH). However, in my experience, this is seldom the case, and there are frequently differences you have to reconcile. If you count more or less of a product than you anticipated, you will need to investigate the discrepancy to figure out where things went wrong.

There are two primary reasons for inventory shrinkage. Either there has been a clerical error, or theft has occurred. Sometimes, clerical errors are not actual losses—an item could have been misplaced or a key mistyped. Other times, shrinkage indicates actual loss, and you should investigate where it happened so you can work on preventing shrinkage in the future .

As retail theft increased (and continues to do so), retail shrink was worth $100 billion in 2022. Learn how to prevent theft with our guide to retail theft prevention strategies .

If you determine that your missing merchandise is truly gone, you should adjust your QOH in your records or inventory management system/POS. After that, you need to record the dollar value lost due to the shrinkage in your inventory.

Inventory Management System Quiz

Thinking you want to automate your inventory management and use software instead of a manual application?

Answer a few simple questions and get matched with the best inventory management system for your business and its needs.

What kind of business do you operate?

Question 1 of 4

1 minute approx

How many inventory units do you process monthly?

Question 2 of 4

Do you already use a POS system?

Question 3 of 4

Why do you want an inventory management system?

Question 4 of 4

Inventory Management Frequently Asked Questions (FAQs)

Expand the questions below to get answers to some of your most asked questions about inventory management.

What is inventory management?

Inventory management is the process (or all the processes) involved in keeping the right products, in the right quantity, in stock at the right times. In other words, inventory management is anything you do to avoid stockouts and to have in-demand products in stock for your customers to buy when they want them.

What is the best inventory management system for small businesses?

Overall, our top pick for inventory management systems for small businesses is Zoho Inventory. For retailers specifically, however, we recommend Lightspeed.

How do you do inventory management?

To do inventory management, you first need to organize your existing products and vendor info, place purchase orders, receive your orders, tag and label new inventory, organize it into your storage area, and then continually track and count inventory over time so you can monitor when it is time to place new orders or put items on sale.

How do small companies manage inventory?

Small business inventory management involves using a spreadsheet and tracking by hand or with an inventory management software solution to automate the process—and it isn’t very different for larger companies. We suggest Square as a free option that is perfect for small companies. Learn how to use Square to manage your business.

A good inventory management system means that you always have an accurate picture of your stock so that you can avoid waste and provide the merchandise and experience that your customers expect. Whether you’re looking to learn the basics of how to organize inventory for small businesses or reinvigorate an existing system that has become disorganized, these steps will help you set up and streamline your operations.

About the Author

Find Brigitte On LinkedIn

Brigitte Korte

Brigitte is a retail specialist and staff writer with brick-and-mortar management experience. Before joining FSB, she managed a storefront for several years, working in everything from merchandising, to buying, to sales analysis. Brigitte also has a background in writing, research, and publishing, with an undergraduate degree in writing.

By downloading, you’ll automatically subscribe to our weekly newsletter.

Join Fit Small Business

Sign up to receive more well-researched small business articles and topics in your inbox, personalized for you. Select the newsletters you’re interested in below.

- Search Search Please fill out this field.

- Corporate Finance

Inventory Management Defined, Plus Methods and Techniques

Adam Hayes, Ph.D., CFA, is a financial writer with 15+ years Wall Street experience as a derivatives trader. Besides his extensive derivative trading expertise, Adam is an expert in economics and behavioral finance. Adam received his master's in economics from The New School for Social Research and his Ph.D. from the University of Wisconsin-Madison in sociology. He is a CFA charterholder as well as holding FINRA Series 7, 55 & 63 licenses. He currently researches and teaches economic sociology and the social studies of finance at the Hebrew University in Jerusalem.

:max_bytes(150000):strip_icc():format(webp)/adam_hayes-5bfc262a46e0fb005118b414.jpg)

What Is Inventory Management?

Inventory management refers to the process of ordering, storing, using, and selling a company's inventory. This includes the management of raw materials, components, and finished products, as well as warehousing and processing of such items. There are different types of inventory management, each with its pros and cons, depending on a company’s needs.

Key Takeaways

- Inventory management is the entire process of managing inventories from raw materials to finished products.

- Inventory management tries to efficiently streamline inventories to avoid both gluts and shortages.

- Four major inventory management methods include just-in-time management (JIT), materials requirement planning (MRP), economic order quantity (EOQ) , and days sales of inventory (DSI).

- There are pros and cons to each of the methods, reviewed below.

Investopedia / Alex Dos Diaz

The Benefits of Inventory Management

A company's inventory is one of its most valuable assets. In retail, manufacturing, food services, and other inventory-intensive sectors, a company's inputs and finished products are the core of its business. A shortage of inventory when and where it's needed can be extremely detrimental.

At the same time, inventory can be thought of as a liability (if not in an accounting sense). A large inventory carries the risk of spoilage, theft, damage, or shifts in demand. Inventory must be insured, and if it is not sold in time it may have to be disposed of at clearance prices—or simply destroyed.

For these reasons, inventory management is important for businesses of any size. Knowing when to restock inventory, what amounts to purchase or produce, what price to pay—as well as when to sell and at what price—can easily become complex decisions. Small businesses will often keep track of stock manually and determine the reorder points and quantities using spreadsheet (Excel) formulas. Larger businesses will use specialized enterprise resource planning (ERP) software. The largest corporations use highly customized software as a service (SaaS) applications.

Appropriate inventory management strategies vary depending on the industry. An oil depot is able to store large amounts of inventory for extended periods of time, allowing it to wait for demand to pick up. While storing oil is expensive and risky—a fire in the U.K. in 2005 led to millions of pounds in damage and fines—there is no risk that the inventory will spoil or go out of style. For businesses dealing in perishable goods or products for which demand is extremely time-sensitive—2021 calendars or fast-fashion items, for example—sitting on inventory is not an option, and misjudging the timing or quantities of orders can be costly.

For companies with complex supply chains and manufacturing processes, balancing the risks of inventory glut and shortages is especially difficult. To achieve these balances, firms have developed several methods for inventory management, including just-in-time (JIT) and materials requirement planning (MRP) .

Some companies, such as financial services firms, do not have physical inventory and so must rely on service process management.

Accounting for Inventory

Inventory represents a current asset since a company typically intends to sell its finished goods within a short amount of time, typically a year. Inventory has to be physically counted or measured before it can be put on a balance sheet. Companies typically maintain sophisticated inventory management systems capable of tracking real-time inventory levels.

Inventory is accounted for using one of three methods: first-in-first-out (FIFO) costing; last-in-first-out (LIFO) costing; or weighted-average costing . An inventory account typically consists of four separate categories:

- Raw materials — represent various materials a company purchases for its production process. These materials must undergo significant work before a company can transform them into a finished good ready for sale.

- Work in process (also known as goods-in-process ) — represents raw materials in the process of being transformed into a finished product.

- Finished goods — are completed products readily available for sale to a company's customers.

- Merchandise — represents finished goods a company buys from a supplier for future resale.

Inventory Management Methods

Depending on the type of business or product being analyzed, a company will use various inventory management methods . Some of these management methods include just-in-time (JIT) manufacturing, materials requirement planning (MRP), economic order quantity (EOQ) , and days sales of inventory (DSI) . There are others, but these are the four most common methods used to analyze inventory.

1. Just-in-Time Management (JIT)

This manufacturing model originated in Japan in the 1960s and 1970s. Toyota Motor ( TM ) contributed the most to its development. The method allows companies to save significant amounts of money and reduce waste by keeping only the inventory they need to produce and sell products. This approach reduces storage and insurance costs, as well as the cost of liquidating or discarding excess inventory.

JIT inventory management can be risky. If demand unexpectedly spikes, the manufacturer may not be able to source the inventory it needs to meet that demand, damaging its reputation with customers and driving business toward competitors. Even the smallest delays can be problematic; if a key input does not arrive "just in time," a bottleneck can result.

2. Materials Requirement Planning (MRP)

This inventory management method is sales-forecast dependent, meaning that manufacturers must have accurate sales records to enable accurate planning of inventory needs and to communicate those needs with materials suppliers in a timely manner. For example, a ski manufacturer using an MRP inventory system might ensure that materials such as plastic, fiberglass, wood, and aluminum are in stock based on forecasted orders. Inability to accurately forecast sales and plan inventory acquisitions results in a manufacturer's inability to fulfill orders.

3. Economic Order Quantity (EOQ)

This model is used in inventory management by calculating the number of units a company should add to its inventory with each batch order to reduce the total costs of its inventory while assuming constant consumer demand. The costs of inventory in the model include holding and setup costs.

The EOQ model seeks to ensure that the right amount of inventory is ordered per batch so a company does not have to make orders too frequently and there is not an excess of inventory sitting on hand. It assumes that there is a trade-off between inventory holding costs and inventory setup costs, and total inventory costs are minimized when both setup costs and holding costs are minimized.

4. Days Sales of Inventory (DSI)

This financial ratio indicates the average time in days that a company takes to turn its inventory, including goods that are a work in progress, into sales. DSI is also known as the average age of inventory, days inventory outstanding (DIO), days in inventory (DII), days sales in inventory or days inventory and is interpreted in multiple ways.

Indicating the liquidity of the inventory, the figure represents how many days a company’s current stock of inventory will last. Generally, a lower DSI is preferred as it indicates a shorter duration to clear off the inventory, though the average DSI varies from one industry to another.

Inventory Management Red Flags

If a company frequently switches its method of inventory accounting without reasonable justification, it is likely its management is trying to paint a brighter picture of its business than what is true. The SEC requires public companies to disclose LIFO reserve that can make inventories under LIFO costing comparable to FIFO costing.

Frequent inventory write-offs can indicate a company's issues with selling its finished goods or inventory obsolescence. This can also raise red flags with a company's ability to stay competitive and manufacture products that appeal to consumers going forward.

What Are the Four Main Types of Inventory Management?

The four types of inventory management are just-in-time management (JIT), materials requirement planning (MRP), economic order quantity (EOQ) , and days sales of inventory (DSI). Each inventory management style works better for different businesses, and there are pros and cons to each type.

How Did Tim Cook Use Inventory Management at Apple?

Tim Cook is known as an inventory genius. “Inventory is like dairy products,” Cook is quoted saying. “No one wants to buy spoiled milk.” For this reason, inventory management can save a company millions.

What Is an Example of Inventory Management?

Let's look at an example of a just-in-time (JIT) inventory system. With this method, a company receives goods as close as possible to when they are actually needed. So, if a car manufacturer needs to install airbags into a car, it receives airbags as those cars come onto the assembly line instead of having a stock on supply at all times.

The Bottom Line

Inventory management is a crucial part of business operations. Proper inventory management depends on the type of business and what type of product it sells. There may not be one perfect type of inventory management, because there are pros and cons to each. But taking advantage of the most fitting type of inventory management style can go a long way.

Competent Authority. “ Buncefield: Why Did it Happen? ,” Page 34.

Toyota. “ Toyota Production System ,” Pages 1-2.

Chartered Institute of Procurement and Supply. “ How to Do Effective Material Requirements Planning .”

Kumar, Rakesh. “ Economic Order Quantity (EQQ) Model .” Global Journal of Finance and Economic Management , vol. 5, no 1, 2016, pp. 1-2.

:max_bytes(150000):strip_icc():format(webp)/terms_j_jit_FINAL_-48745eb8661844c4becbbaafbf322320.jpg)

- Terms of Service

- Editorial Policy

- Privacy Policy

- Your Privacy Choices

- Skip to content

- Accessibility Policy

- QUICK LINKS

- Oracle Cloud Infrastructure

- Oracle Fusion Cloud Applications

- Oracle Database

- Download Java

- Careers at Oracle

- Create an Account

Inventory Management System—Overview

What is inventory management?

Inventory management: financial implications, what are the types of inventory management systems, radio-frequency identification (rfid) system and inventory management systems, inventory management vs. cycle counting, inventory management examples—industry use cases, inventory management software, cloud inventory management—where are you in your journey.

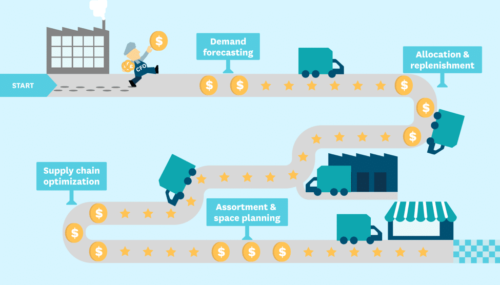

Inventory management is the process of orchestrating the flow of goods through a company in a continuous cycle of ordering, storing, producing, selling, and restocking goods. Inventory management is generally performed at two levels: aggregate inventory management and stocking location and item-level inventory management. In determining their, inventory strategy, companies make tradeoffs between minimizing the amount of cash tied up in inventory or holding more inventory to maximize customer service or production efficiency.

Inventory strategy involves inventory management at the item level through policies, such as safety stock (described later), and to inventory controls through polices, such as ABC classification to prioritize replenishment rates, which take item level attributes, such as consumption value, lot sizes and order lead times, into account.

Inventory can be broadly classified into three categories: raw materials/components, work in progress, and finished goods. Manufacturing companies purchase raw materials or components, store them until ready for production, and transform them into finished goods. Nonmanufacturing companies, such as wholesale distributors and retailers, stock finished goods for sale to final consumers.

All companies must strike a balance between inventory levels and demand because inventory consumes a company’s cash and incurs carrying costs. Regardless of the type of business, companies must maintain tight control over inventory to conserve cash while ensuring they have enough stock to meet production schedules or forecasted customer demand and actual orders.

Benefits of inventory management

Inventory management is complex and varies depending on your industry, your function within the company, and the type of item being managed. Deciding how to plan and manage inventory is a collaborative effort full of trade-offs, risks, and rewards.

No two companies are alike. Depending on their business model, companies use a number of different methods to manage inventory. Inventory costs the company money, but it may be necessary to hold more safety stock to maintain superior service levels to avoid stockouts and to maximize operational efficiency. Manufacturers with expensive machine and people operations will sometimes carry excess inventory to avoid shutting down these operations due to a lack of inventory—which would cost the company more money.

Almost all companies maintain safety stock inventory to protect against unexpected changes in supply and demand. In this way, inventory functions as a protection against the unexpected, and as a buffer against production shutdowns. Safety stock represents a balance between service or fill rates (the percentage of customer orders that a company can ship immediately from stock) and the additional cost of ordering and holding more inventory. The consequence of not having enough inventory are stock-outs, which can be detrimental to a business especially if customers have alternatives, such as ecommerce-based businesses where rapid fulfillment is expected. Stock-outs represent lost revenue and can adversely affect customer loyalty.

Manufacturers typically establish inventory controls, such as minimum and maximum stocking levels and reorder points, within their ERP systems. Distributors establish reorder points in a decentralized manner, allowing each distribution center to determine their inventory levels based on local factors or demand-driven methods. Local factors can include SKU-level demand, lead times, or seasonal patterns. Demand-driven methods can include point-of-sale data from their retail customers. Many procurement organizations take pricing discounts into consideration in their purchasing strategy and may buy more supply than required to obtain favorable price points.

Inventory management involves making trade-offs between revenue, cost, and risk. Classified on the balance sheet as a current asset, inventory consumes company cash. Careful attention must be paid to the length of the cash conversion cycle—the time between purchasing raw materials (for a manufacturer) or merchandise (wholesaler or retailer) to the final sale of finished products and receipt of payments from customers.

During that time, cash remains tied up, and companies must ensure their inventory is sold in a timely manner (called inventory turns) to return the cash to the business. Slow-moving inventory incurs holding costs, risks, and adversely affects a company’s cash flow. Accordingly, companies require a disciplined process to ensure that the level of inventory investment is in line with the expected level of customer demand.

Inventory management also requires rigorous costing to support both internal management reporting and statutory financial reporting. Inventory costs used in production must comply with absorption costing methods for allocating both direct and indirect labor and overhead to products as they take shape on the production line. And the finished goods, also referred to as merchandise inventory, require allocating any costs associated with preparing it for sale.

These costs can include transportation, labor, and other handling expenditures. An aggregate, the sum of all inventory across the company is used to determine the inventory line item on the balance sheet and the cost of goods sold on the income statement.

Businesses employ a variety of inventory management systems, depending on their operations, complexities, or needs. Examples of the three primary inventory management systems are manual, periodic, and perpetual. Perpetual systems are the most advanced and accurate inventory management systems, whereas the manual method is the least sophisticated way to oversee inventory operations.

Manual inventory system : This method of managing inventory depends on the physical counting of items and recording the details on paper or in a spreadsheet. This process is widely used by small businesses that have not moved to inventory management software solutions.

Periodic inventory system : This is an inventory management system where the inventory count is performed at the end of an accounting period rather than after every sale and purchase. It’s a relatively simple system that’s better suited for smaller businesses with fewer goods.

Perpetual inventory system : The system is the most sophisticated, leveraging automated software solutions to deliver real-time insights. As soon as any stock enters a facility, is moved, sold, used, or discarded, the inventory system will update balances immediately aided by scans from hand held devices that scan item barcodes or RFID tags.

RFID is a technology tracking system that supports inventory management systems. RFID systems use specialized tags attached to every item to track its whereabouts. RFID simplifies inventory management by scanning newly arrived shipments into the system or outbound shipments using mobile scanners. RFID tags can be active, continually broadcasting a signal, or passive, requiring physical readers to track items. RFID tags are the best for providing real-time data and insights on where inventory at all times.

Cycle counting is a method of checks and balances to confirm that physical inventory counts match a company’s inventory records. The periodic counting of individual items throughout the year ensures the accuracy of inventory quantities and values.

Having an accurate system of tracking on-hand inventory quantities is essential for managing supply and demand, maintaining high customer service levels, and planning production.

Instead of leveraging inventory management systems, you can perform cycle counting to take complete physical inventories. Or businesses can use both techniques side-by-side to verify inventory quantities and values. Inventory management supports serialized cycle counting.

While inventory management is common across most industries, there are particular industries with unique requirements that warrant specialized systems. Notable examples are food service (restaurants) and retail.

Retail inventory management

Today, retailers must offer very flexible customer buying options for goods that are offered through different channels. Intense competition from large ecommerce vendors and demanding customers have forced retailers to operate a mixed business model, combining brick-and-mortar stores and online buying experiences, referred to as omnichannel retail.

Omnichannel provides buyers with flexible options, such as order in store, ship to home, buy online, return in store, or ship from a distributor to a store for pickup. The goal is delivering an excellent end-to-end customer experience which could mean the difference between success and going out of business.

In order provide the best customer experience through omnichannel, retailers need to have real-time visibility into their stock on hand to ensure that the customer shopping experience results in orders. Stockouts not only prevent specific orders from being filled, but frustrated customers are also very likely to look for similar items on a competitor’s store or website. Loyalty is fleeting and brand switching is common. Lost customers may never return affecting potential future sales.

As a result, retailers need to manage inventory very carefully to finesse the fine line between having enough inventory to fill the highest percentage of their customer orders and not having too much which strains their cash flow and risks having left over stock at the end of a buying season that cannot be sold. Retail inventory management software (combined with order management systems) allow retailers to swiftly react to changes in buying behavior and adjust their channel strategies and inventory levels.

Restaurant inventory management

Managing restaurant inventory is unique in that it must provide real-time ingredients monitoring because many are fresh, have short shelf lives and carefully tracked through to consumption. The system must also carefully monitor stock levels, trigger restocking orders, record new inventory receipts, and help manage menu costs.

Managing fresh ingredients has inherent challenges by helping managers to closely monitor their shelf lives to prevent spoilage. At best, spoilage results in wasted money, while worst case, it can cause food poisoning and trigger actions from health authorities.

Inventory management software can help restaurants manage their unique challenges. By automatically connecting sales with inventory levels, restaurants can have a complete view of orders, consumption, insight into ingredients stocks, avoid spoilage and manage their margins. Inventory management software also reduces time spent on administrative tasks by sending alerts to managers about potential shelf life expirations, automate reordering when items exceed their spoilage dates or fall below set replenishment levels.

Modern, cloud-based inventory management systems provide comprehensive materials management capabilities that effectively manage the flow of goods across your company and its global supply network. In conjunction with warehouse management systems , they provide accurate and timely visibility into inventory levels, restocking plans and order fill rates, all effect customer satisfaction. Combined with supply chain planning systems, they take the guesswork out of inventory management by matching demand with supply through optimizing stocking levels, increasing order fill rates, ensuring on-schedule production runs, and improving working capital utilization.

Inventory management and supply chain management

Inventory management is a critical component of supply chain management in that a supply chain’s reason for being is the movement of goods, either delivering raw materials and subcomponents to manufacturers or fulfilling orders for finished goods to consumers. Both help companies reduce costs, improve cash flow, and increase profit margins.

Inventory visibility

A key benefit of modern cloud inventory management solutions is their ability to provide real-time visibility into inventory across multiple nodes of the supply chain, such as production facilities, suppliers, goods in transit, and distribution centers. This gives decision-makers the insights they need to maintain customer satisfaction. This is particularly critical for companies with extended supply networks, variable demand and intense competition.

A real-time view of stocking levels and their location helps them better manage production schedules and customer order processing. For example, if a delivery is held up due to transportation problems, managers can cover the temporary shortfall by shifting stock from one distribution center to another where higher demand levels warrant having more inventory.

Combined with supply chain planning software , having real-time data on order volumes helps planners determine how much of a particular item they need, where it should be located, and how frequently they need to restock in order to meet actual and forecasted demand and production levels.

Integrated supply chain planning

Complex supply chains challenge companies to align supply with demand and determine inventory levels with greater precision. Sophisticated demand planning solutions can help utilizing sophisticated algorithms that incorporate multiple scenarios including item and location combinations as well as inventory policies to generate the optimal demand plan. What-if scenarios play a vital role in ensuring planned inventory levels will be sufficient to meet customer demand, avoid stock-outs, and ensure resiliency.

Managing suppliers to optimize inventory management

Choosing the right suppliers is the responsibility of the Procurement organization. Suppliers can have a significant impact on inventory. For example, achieving just-in-time availability depends on having reliable, qualified suppliers that can meet specific delivery timelines. If they miss scheduled shipping dates, production and customer orders may be delayed, resulting in decreased customer satisfaction.

The net requirements plan incorporated through supply planning into the demand plan must be able to support the complexity of global supply chains to determine raw materials and component inventory requirements for production. Finally, planning systems help determine inventory policies for setting safety stock levels (excess inventory used as a buffer against supply and demand uncertainty) basically taking the guesswork out of inventory decisions and their potential negative impact on cash flow.

Integrated business planning combines statistical forecasts with actual demand signals to provide up to date forecasts and inventory levels that meet your desired or target customer service levels. It helps you manage uncertainty in demand and supplier lead times. Replenishment orders are generated whenever an inventory position falls below a minimum threshold. These orders incorporate estimated lead times to ensure adequate stocking levels. Based on the specified inventory policy, the replenishment order may be a fixed order quantity or computed quantity, calculated as a difference between the maximum threshold and inventory position, and can be adjusted for minimum order quantities.

If you’re ready to learn more about modern inventory management, a good place to start is by asking yourself the following questions:

- Are we optimizing our inventory by aligning it with demand and supply planning?

- Are we using the right inventory policies to minimize inventory cost and maximize customer service?

- Is fragmentation of inventory hindering our ability to execute?

- How are we managing our safety stocks?

- How much of our working capital is tied up in inventory?

- How can we improve our inventory turns?

- How is inventory availability supporting our customer satisfaction goals?

Many companies are still using spreadsheets or inflexible legacy systems for some or all aspects of inventory management. While that approach might seem adequate, older technologies can lead to suboptimal business outcomes. To compete in a today’s complex supply chains and respond adequately to inevitable disruptions, you need modern cloud solutions that share information in real time to achieve better alignment between planning, production and an integrated view of your inventory.

Cloud-based integrated supply chain management (SCM) suites help companies develop synergies across their planning and inventory management, as well as other crucial supply chain functions, such as procurement, manufacturing, logistics, and order management. The result: greater efficiency, customer service, and higher profit margins.

Where are you in your journey to integrated inventory management? How can we help?

- Free Subscription

- Whitepapers

- Web-Cite City

- Knowledge Center

Inventory Management: Definition, Types, and Examples

Effective inventory management is the unsung hero of successful business operations, whether in the bustling retail world or in systematic manufacturing processes.

It’s a critical component that can dictate a company’s ability to meet customer demand, manage cash flow, and maintain a competitive edge.

According to a report by the National Retail Federation , the retail industry loses nearly $50 billion annually due to inventory shrinkage, a problem that effective inventory management can mitigate

By leveraging data and modern inventory management systems, businesses can ensure that inventory levels are optimized, excess inventory is minimized, and inventory costs are controlled.

This foundational aspect of supply chain management affects the balance sheets and impacts customer satisfaction and business agility.

In this article, we will share inventory management definitions, explain inventory management meaning, give an inventory example, and discuss how inventory management relates to both inbound and outbound logistics.

Inventory Management Defined

Inventory management refers to ordering, storing, using, and selling a company’s inventory. This includes managing raw materials, components, finished goods, and warehousing and processing of such items.

Automotive and healthcare industries rely on effective inventory management to streamline production processes and reduce hold-ups. Historically, inventory management was a manual process.

Still, today it has evolved into a sophisticated inventory management system integrated with supply chain logistics, thanks to advancements in technology like Enterprise Resource Planning (ERP) systems and inventory management software. These tools provide real-time data that businesses use to efficiently forecast, plan, and execute their inventory management processes.

Advantages of Inventory Management and Supply Chain

The advantages of sound inventory management are manifold. Primarily, it allows businesses to have the right products available at the right time, which is crucial for meeting customer orders and maintaining solid sales channels. This is particularly crucial for the inbound logistics process.

Good inventory management can lead to better inventory turnover, ensuring fresh and relevant products, which is especially important in industries with rapid product lifecycles, such as fashion or technology.

Also, effective inventory management reduces costs by decreasing the need for excess inventory and storing inventory, which can drain resources and capital if not appropriately managed.

Inventory vs. Stock Explained

While often used interchangeably, inventory and stock have subtle distinctions.

Inventory encompasses more than just the products available for sale (stock); it includes raw materials, work-in-progress items, and all components involved in the production process.

Understanding this nuance is vital, as it affects how businesses plan their inbound logistics, procurement and manage inventory levels across the supply chain.

Counting Inventory

Counting inventory , or taking a physical list, is a crucial task that validates the quantity and condition of items on hand. It’s a fundamental process that informs financial reporting, inventory forecasting, and supply chain planning.

Accurate counts are essential for maintaining inventory data integrity, which impacts everything from order management to customer satisfaction. This process is critical at the end of accounting periods to ensure that reported inventory levels reflect the actual value of assets held by the company.

Types of Inventory Management Methods

Several methods help businesses optimize their handling of goods and materials.

Just-in-Time Management (JIT)

Just-in-Time Management (JIT) is a strategy where inventory is delivered only as it is needed in the production process, reducing the cost of storing inventory. Significant for industries like automotive manufacturing , JIT can lead to reduced inventory levels and associated costs, promoting an efficient supply chain.

Materials Requirement Planning (MRP)

Materials Requirement Planning (MRP) systems calculate the materials and components required to manufacture a product. This method is vital for manufacturing industries, ensuring that materials are available for production without the excess that can tie up capital.

Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) is a formula used to determine the optimal order quantity that minimizes inventory costs involving holding and ordering costs. This is significant across various industries for maintaining balance in inventory management.

Days Sales of Inventory (DSI)

Days Sales of Inventory (DSI) measures how quickly a company can turn its inventory into sales. A lower DSI indicates that a company is more efficient at selling off its stock. This metric is critical for retailers to gauge their inventory management efficiency.

Common Problems within Inventory Management

Though crucial, inventory management is fraught with challenges that can ripple through the supply chain and impact logistics operations.

One common issue is overstocking, which ties up cash flow and can lead to excess inventory that may become obsolete or expire. Conversely, understocking risks stockouts, leading to delays in the production process and dissatisfied customers.

Prominent Examples of Inventory Management

Inventory management plays a crucial role in industries where products have a limited shelf life, such as food and beverage or pharmaceuticals . Here, it’s pivotal to prevent spoilage and ensure compliance with safety regulations.

In fashion retail, inventory management must be dynamic to keep up with changing trends and seasonal demand, making it essential for maintaining inventory freshness and reducing instances of dead stock.

Disadvantages of Inventory Management

Despite its many benefits, inventory management can have downsides. Holding inventory inherently involves storage costs, and stock that sits in a warehouse too long can lead to increased expenses without generating revenue.

Moreover, complex inventory management systems can be costly to implement and maintain, requiring significant technological and training investments. These systems can sometimes lead to a dependency that may cripple operations if the system goes down or is attacked by cyber threats .

Inventory Management and Software

Inventory management software has revolutionized how companies approach their inventory processes. This technology allows for real-time tracking of goods, inventory forecasting, and more accurate demand planning.

Inventory Management vs. Supply Chain Management

While inventory management focuses on overseeing and controlling goods within a company, supply chain management encompasses a broader scope, managing the entire flow of goods and materials from suppliers to the end customer.

Tracking Inventory and Internal SKU Systems

Tracking inventory through internal Stock Keeping Units (SKUs) is an intricate part of inventory management. SKUs help businesses quickly categorize and locate inventory, facilitating faster inventory turnover and more precise inventory data.

Forecasting and Controlling Inventory with Software

Modern inventory management software often includes sophisticated forecasting tools that utilize historical sales data, seasonal trends, and other variables to predict future demand. This predictive capability helps businesses maintain optimal inventory levels, reducing the risk of overstocking or stockouts.

Types of Successful Inventory Management Techniques

A variety of inventory management techniques are employed by businesses to maintain efficiency and cost-effectiveness in managing stock levels.

These methods are tailored to match the needs of the company and the nature of the inventory it holds.

Economic and Minimum Order Quantity

Economic Order Quantity (EOQ) and Minimum Order Quantity (MOQ) are foundational concepts in inventory management.

EOQ calculates the ideal order quantity to minimize total inventory costs, while MOQ determines the minuscule amount a supplier is willing to sell. Both are vital for optimizing inventory levels and reducing costs.

ABC Analysis

ABC Analysis categorizes inventory into three categories (A, B, and C) based on importance and volume.

‘A’ items are high-priority with stringent control, ‘B’ are moderate, and ‘C’ have the most negligible financial impact. This prioritization is essential for efficient inventory control.

Just-In-Time Inventory

Just-In-Time (JIT) inventory management is a strategy that aligns raw-material orders with production schedules to minimize inventory costs.

It’s crucial for businesses looking to reduce waste and increase efficiency in the production process.

Safety Stock

Safety Stock is additional inventory held to prevent stockouts caused by inaccuracies in demand forecasting or supply chain disruptions.

It’s a critical buffer that ensures customer demand is met without delay.

First In-First Out (FIFO) vs. Last In-First Out (LIFO) Explained

FIFO and LIFO are methods to manage the flow of inventory costs. FIFO assumes the first items stocked are the first sold, reducing the chance of obsolete inventory.

LIFO, less common, takes the last things in are the first sold, which can benefit in specific tax situations.

Reorder Triggers

Reorder triggers are pre-determined inventory levels that prompt a new purchase order.

They are vital for maintaining stock levels and ensuring consistent supply without overstocking, playing a significant role in inventory management systems.

Batch Tracking

Batch tracking monitors the production and expiration dates of batches of inventory items.

It’s crucial for traceability in case of recalls and managing stock with expiration dates, maintaining the integrity of the supply chain.

Consignment Inventory

Consignment inventory allows retailers to stock goods without purchasing them upfront; payment is made only after the sale.

This method is vital for inventory management as it reduces the retailer’s capital in inventory and transfers the risk of unsold stock to the supplier.

Perpetual Inventory

A perpetual inventory system continuously tracks inventory levels, updating in real-time with every sale and restock.

It’s essential for accurate inventory data, allowing for timely ordering and reduction of excess stock.

Dropshipping

Dropshipping is a retail fulfillment method where a store doesn’t keep products in stock but instead transfers customer orders and shipment details to the manufacturer or a wholesaler, who then ships the goods directly to the customer.

This method is vital as it eliminates the need for managing physical inventory, significantly reducing handling and storage costs.

Lean Manufacturing

Lean manufacturing emphasizes waste reduction within the manufacturing system without sacrificing productivity.

It’s vital for inventory management as it promotes a just-in-time approach, minimizing stock levels and reducing holding costs.

Six Sigma and Lean Six Sigma Techniques

Six Sigma and Lean Six Sigma focus on quality improvement and process efficiency.

They are vital to inventory management by identifying and eliminating process defects, resulting in lower inventory costs and improved customer satisfaction.

Demand Inventory Forecasting

Demand inventory forecasting uses historical sales data to predict customer demand and manage inventory accordingly.

It’s essential for preventing stockouts and overstock, making inventory management more responsive and cost-effective.

Cross-Docking

Cross-docking is a logistics procedure where products from a supplier or manufacturing plant are distributed directly to a customer or retail chain with marginal to no handling or storage time.

It’s vital as it reduces the need for warehousing while increasing inventory turnover rates.

Bulk Shipments

Bulk shipments involve transporting large quantities of a single product, which can significantly reduce transportation costs.

It’s vital for inventory management as it can lead to economies of scale, making larger shipments more cost-effective.

Cycle Counts

Cycle counting is an inventory auditing procedure where a small subset of inventory in a specific location is counted on a particular day. It contrasts with traditional physical inventory counting, where operations are halted to count all inventory.

Cycle counts are less disruptive and more accurate, allowing for regular verification of inventory accuracy and providing ongoing insights into inventory levels without the operational shutdown.

The Significance of Inventory Management, Control and Optimization

Effective inventory management, control, and optimization methods are crucial for maintaining the delicate balance between too much and too little inventory.

They ensure that capital is not unnecessarily tied up in stock, preventing stockouts that can lead to lost sales. These methods can result in improved cash flow, better customer service levels, and the ability to quickly respond to market changes.

How Inventory Affects Logistics

Inventory levels directly impact logistics operations; having the right stock in the right place at the right time is essential for effective logistics.

High inventory levels can cause bottlenecks and increase storage costs, while lower inventory levels can result in inefficient transportation and higher shipping costs for urgent replenishment.

ERP Inventory Management Style

ERP inventory management incorporates all facets of a company’s inventory system into a unified system, including tracking, management, and forecasting.

This method offers comprehensive insights into inventory, streamlines processes, and can improve overall efficiency.

Retail and Manufacturing Inventory Management

Inventory management in retail focuses on having the right products available to meet consumer demand while manufacturing inventory management ensures that production materials are at hand without overstocking.

Both require strategies that optimize stock levels, though retail is more directly driven by consumer trends, and production schedules and supplier lead times influence manufacturing.

Unveil the essentials of inventory management with these succinctly answered frequently asked questions.

What does inventory management do?

Inventory management oversees stock levels, manages orders, and forecasts demand to optimize business operations.

What are the 4 types of inventory?

The four types are raw materials, work-in-progress, finished goods, and maintenance, repair, and operations (MRO) inventories.

What are the 3 major inventory management techniques?

The three main techniques are Just-In-Time, ABC Analysis, and Economic Order Quantity (EOQ).

Inventory Management Techniques Summary

Effective inventory management is a cornerstone of successful business operations, ensuring that inventory levels are balanced, customer demand is met, and inventory costs are minimized.

Businesses can enhance their supply chain management and maintain a competitive edge in today’s market by employing strategic inventory management techniques, such as Just-In-Time and Economic Order Quantity.

Additionally, advancements in inventory management software have made it easier for companies to track and manage their inventory more efficiently, further optimizing their inventory management processes.

Visit Our Sponsors

Inventory management, a critical element of the supply chain, is tracking inventory from manufacturers to warehouses and from these facilities to the point of sale. Inventory management aims to have the right products in the right place at the right time.

Inventory management requires inventory visibility, knowing when to order, how much to order and where to store stock. Multichannel order fulfillment operations typically have inventory spread across many places throughout the supply chain. Businesses need an accurate view of inventory to guarantee fulfillment of customer orders, reduce shipment turnaround times and minimize stockouts, oversells and markdowns.

Take a look at the trends shaping the world of sustainable business and the insights that can help drive transformation.

Register for the guide to the EU's CSRD

The basic steps of inventory management include:

- Purchasing inventory: Ready-to-sell goods are purchased and delivered to the warehouse or directly to the point of sale.

- Storing inventory: Inventory is stored until needed. Goods or materials are transferred across your fulfillment network until ready for shipment.

- Profiting from inventory: The amount of product for sale is controlled. Finished goods are pulled to fulfill orders. Products are shipped to customers.

Inventory can be a company’s most important asset. Inventory management is where all the elements of the supply chain converge. Too little inventory when and where it's needed can create unhappy customers. But a large inventory has its own liabilities, the cost to store and insure it, and the risk of spoilage, theft and damage. Companies with complex supply chains and manufacturing processes must find the right balance between having too much inventory on hand or not enough.

Periodic inventory management The periodic inventory system is a method of inventory valuation for financial reporting purposes in which a physical inventory count is performed at specific intervals. This accounting method takes inventory at the beginning of a period, adds new inventory purchases during the period and deducts ending inventory to derive the cost of goods sold (COGS).

Bar code inventory management Businesses use bar code inventory management systems to assign a number to each product they sell. They can associate several data points to the number, including the supplier, product dimensions, weight and even variable data, such as how many are in stock.

RFID inventory management RFID, or radio frequency identification, is a system that wirelessly transmits the identity of a product in the form of a unique serial number. It tracks items and provides detailed product information. The warehouse management system based on RFID can improve efficiency, increase inventory visibility and ensure the rapid self-recording of receiving and delivery.

Know exactly where inventory is across the supply chain.

Customize pricing, send quotes, track orders and manage returns.

Move the product to where it's most valuable.

Evaluate patterns in processes to forecast future demand and sales.

Create and manage purchase orders.

Automate shipping to reduce errors such as late deliveries or delivering incorrect packages.

Spreadsheets, hand-counted stock levels and manual order placement have largely been replaced by advanced inventory tracking software. An inventory management system can simplify the process of ordering, storing and using inventory by automating end-to-end production, business management, demand forecasting and accounting.

Globalization, technology and empowered consumers are changing the way businesses manage inventory. Supply chain operators will use technologies that provide significant insights into how supply chain performance can be improved. They’ll anticipate anomalies in logistics costs and performance before they occur and have insights into where automation can deliver significant scale advantages.

In the future, these technologies will continue to transform inventory management:

Intelligent, self-correcting AI will make inventory monitoring more accurate and reduce material waste.

Data from IoT sensors will provide insight into inventory location and status.

Disparate parties will be connected through a unified and immutable record of all transactions.

Supply chains will master inventory visibility with improved demand forecasting and automation.

Unprecedented computational power will solve previously unsolvable problems.

Optimize your business operations to enhance customer shopping experiences and prevent inventory stockout and overselling. Gain the real-time inventory visibility you need to manage profitable and scalable omnichannel experiences.

Enhance shopper experiences from discovery to delivery. Preserve brand trust by providing shoppers with greater certainty, choice and transparency across their buying journey.

Accelerate transformation by simplifying technology integrations to deliver omnichannel order fulfillment processes such as real-time inventory and warehouse management, curbside pickup, buy online pickup in store (BOPIS) and ship from store (SFS).

Apply the power of AI to digital supply chain transformation. Improve supply network resiliency and sustainability, increase agility and accelerate time-to-value through actionable insights, smarter workflows and intelligent automation.

Uncover a clearer, more accurate view of your inventory and make informed decisions that help improve margins, increase service levels and minimize unplanned downtime.

The modern digital consumer is increasingly demanding and will abandon retailers that do not meet their expectations.

Today’s customers expect retailers to provide early, accurate and reliable order and delivery promises to shoppers. What happens if retailers don’t meet these promises?

A resilient supply chain must be able to see what is happening (visibility), quickly analyze those events/data (intelligence) and respond appropriately (agility).

IBM Sterling Order Management helps you deliver the perfect order with a complete omnichannel order fulfillment solution built for sustainability. Merge all your sales channels onto one fulfillment platform that helps you accurately track inventory levels, coordinate third-party logistics, organize customer orders, shipping options and returns management, all while reducing shipping costs.

Inventory Management Plan Template

Define inventory objectives, identify inventory items.

- 1 Raw materials

- 2 Finished products

- 3 Spare parts

- 4 Consumables

- 5 Packaging materials

- 1 ABC Analysis

- 2 XYZ Analysis

- 5 Just-in-time (JIT)

Classify inventory items

- 1 High-value items

- 2 Low-value items

- 3 Fast-moving items

- 4 Slow-moving items

- 5 Perishable items

Determine the quantity of each item needed

- 2 Kilograms

Calculate the cost of holding each item

Establish a purchase plan for each item, approval: purchase plan.

- Establish a purchase plan for each item Will be submitted

Determine reorder points for each item

Set up an inventory tracking system.

- 3 Combination

Train staff on inventory management procedures

Initiate initial inventory purchase order, receive and check the accuracy of the inventory purchase order, approval: purchase order accuracy.

- Initiate initial inventory purchase order Will be submitted

- Receive and check the accuracy of the inventory purchase order Will be submitted

Store inventory items properly

Regularly update the inventory tracking system, conduct physical inventory count regularly, compare physical count with system records, investigate and resolve any discrepancies, approval: inventory discrepancies resolution.

- Conduct physical inventory count regularly Will be submitted

- Compare physical count with system records Will be submitted

- Investigate and resolve any discrepancies Will be submitted

Adjust reorder points based on trends and demand changes

Take control of your workflows today., more templates like this.

- Book a demo

What is Inventory Planning? Challenges & Best Practices

Resources / What is Inventory Planning? Challenges & Best Practices

Table of contents +

- Inventory Management: Process, Examples, Tips & Techniques -->

- Accounting for Inventory: Periodic Inventory Management vs Perpetual Inventory Management -->

- Effective Inventory Management in Retail -->

- Multichannel Inventory Management -->

- Inventory Forecasting Best Practices -->

- What is Inventory Tracking? Top Tips for Tracking Inventory -->

- What is Inventory Planning? Challenges & Best Practices -->

- What is lead time and how do you shorten it? -->

- Pipeline Inventory -->

- What is Inventory Control? -->

- Dead Stock: Causes and How to Get Rid of it -->

- Perpetual Inventory System -->

- Inventory management in warehouses -->

- What is Store Inventory Control? -->

- Automated Inventory Management -->

- What is Inventory Turnover? -->