Guide: Kata

Author: Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

Kata, a concept from martial arts, becomes a transformative tool in Lean management, facilitating consistent business improvement. In lean, Kata goes beyond physical movements to embody a mindset of structured thinking and action. It’s a methodical routine for individuals and teams, aiming to refine work processes and tackle challenges.

Kata in Lean includes two main types: Improvement Kata , a cycle of goal setting, assessment, and enhancement; and Coaching Kata , focusing on mentor-led personal development. These methodologies offer a structured approach to problem-solving, skill development, consistency, and cultural change, crucial for sustained operational excellence.

What is Kata?

“Kata,” a term originally rooted in the martial arts world, signifies a sequence or a pattern of movements. When transposed into Lean management, it evolves into a concept that is essential for businesses aiming for consistent improvement. In this context, Kata is less about physical form and more about the form of thought and action.

At its core, “Kata in Lean” is a structured, systematic routine that both individuals and teams adopt to enhance their work processes and address challenges. Think of it as a prescribed set of actions or thoughts that, when practiced consistently, fosters a culture of continuous enhancement and problem-solving. It encapsulates the essence of developing and instilling the right kind of habits that lead to operational excellence.

Delving deeper, there are two pivotal types of Kata in the Lean methodology:

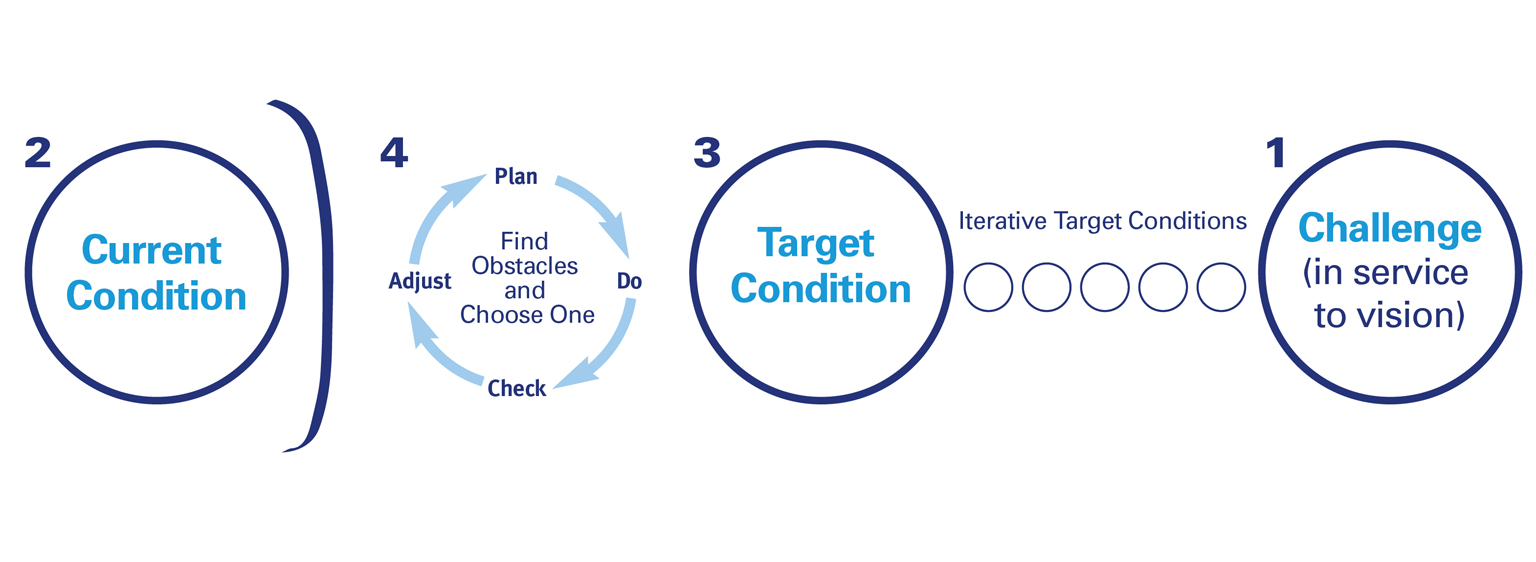

Improvement Kata : The essence of Improvement Kata lies in its cyclical nature. It starts with recognizing and understanding the current state of affairs. Once this baseline is established, the next step is to define a desired or target condition. This isn’t the endgame but a short-term goal that is both challenging and achievable. Once defined, the team then embarks on a journey of iterations, making step-by-step enhancements to bridge the gap between the current and target conditions. It’s a continuous loop of setting goals, assessing the status quo, and making improvements.

Coaching Kata : While Improvement Kata is about the process, Coaching Kata is about the people. It’s a mentor-mentee relationship where the mentor isn’t just an instructor but a guide. The mentor uses a series of well-defined questions, guiding the learner in their problem-solving journey. This ensures not just the resolution of the issue at hand but also that the learner imbibes the principles of the Improvement Kata. The goal is to cultivate a mindset of continuous improvement in the learner.

Want exclusive templates, tools and guides?

Join our email list below and for the next 28 days, we will send you exclusive tools, templates and guides unavailable on the website. We developed a short and simple 28-day program designed to develop your ability to implement Lean and Six Sigma methods daily.

The Significance of Kata in Lean Management

Kata, key in Lean management, it carries profound importance for organizations aiming to sustainably elevate their operational efficiency. Here’s why Kata is indispensable:

Structured Problem Solving : In the unpredictable world of business, challenges are inevitable. However, how one responds to these challenges determines the organization’s resilience and success. Kata, with its structured approach, provides a clear roadmap to navigate these challenges. It emphasizes understanding the current condition, setting a target condition, and then methodically working towards it. This systematic approach eliminates guesswork, ensuring that teams address challenges and performance gaps with precision and clarity.

Development of Skills : One of the fundamental tenets of Kata is repetition. Just as a musician perfects a piece through relentless practice, the repeated application of Kata principles hones an individual’s problem-solving skills. Over time, these practices transition from being deliberate actions to instinctive responses. As team members consistently engage with the Kata methodology, they cultivate an innate ability to address issues efficiently, making robust problem-solving second nature.

Consistency : The business landscape is peppered with stories of organizations that achieved transient success but failed to sustain it. One of the primary reasons is the lack of a consistent approach to improvement. Kata, with its standardized methodology, ensures that all improvements are not just consistent but also sustainable. By following a universal approach across the organization, it ensures that enhancements are replicable, scalable, and sustainable, leading to long-term success.

Cultural Change : Beyond processes and methodologies, Kata plays a pivotal role in shaping the very culture of an organization. It moves the organization away from sporadic, short-term fixes to a mindset of continuous improvement. As teams and individuals embrace Kata, it fosters a culture where every member is oriented towards constant betterment, not just in their tasks but in their thinking.

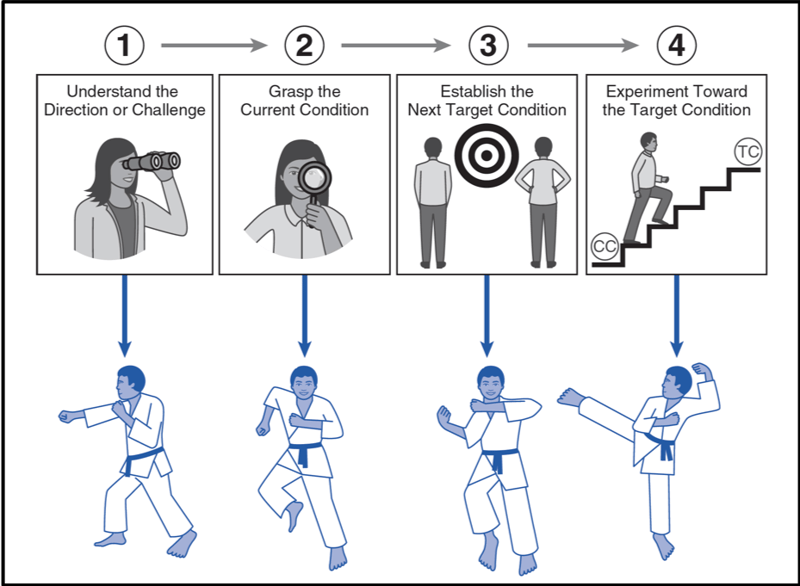

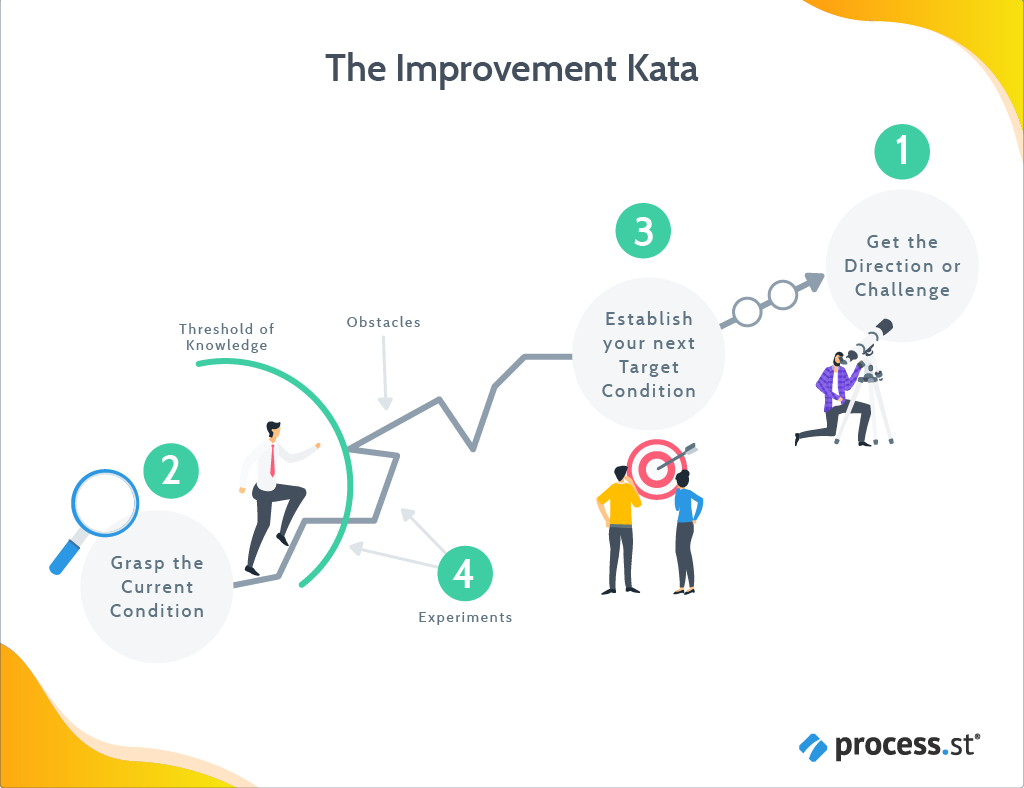

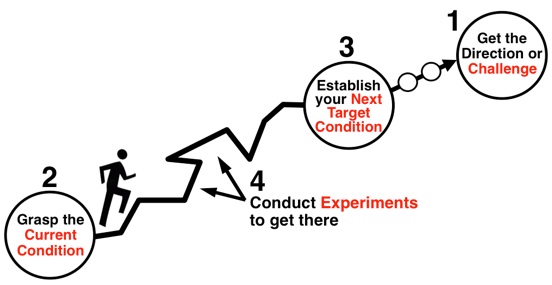

The Four Steps of Improvement Kata

The Improvement Kata is a foundational aspect of Lean management, providing a systematic approach to continuous improvement.

By following its four steps, organizations can navigate from their current state to a desired future state. Let’s dive deeper into these four integral steps:

Understand the Direction or Challenge :

- Significance: Before embarking on any journey, it’s imperative to know the destination. Similarly, before making any improvements, an organization must have a clear understanding of its long-term objectives or challenges.

- Process: This involves setting a vision or a strategic direction. It might be industry benchmarks, best practices, or a visionary goal set by leadership. The essence is to have a challenge that stretches the organization, pushing it out of its comfort zone.

- Outcome: A well-defined direction serves as a north star, guiding all improvement efforts and ensuring alignment with overarching organizational goals.

Grasp the Current Condition :

- Significance: To chart a path forward, one must first know the starting point. This step is about taking a deep dive into the current processes, understanding them intricately.

- Process: This involves data collection, observing processes firsthand, speaking with stakeholders, and mapping out processes. Tools like value stream mapping or process flow diagrams can be invaluable here.

- Outcome: A comprehensive understanding of the present state, complete with identified bottlenecks, inefficiencies, and gaps in performance.

Establish the Next Target Condition :

- Significance: While the direction sets a long-term vision, the target condition is a nearer-term goal, a stepping stone towards that vision.

- Process: Based on the current condition’s insights, set a clear, achievable, and challenging goal for the next phase. This shouldn’t be the final desired state but a progression towards it. It’s about incremental improvement.

- Outcome: A well-defined target that serves as the immediate focus for the team, ensuring efforts are concentrated and aligned.

Experiment Toward the Target Condition :

- Significance: Improvement isn’t a linear path but a series of experiments, learnings, and iterations.

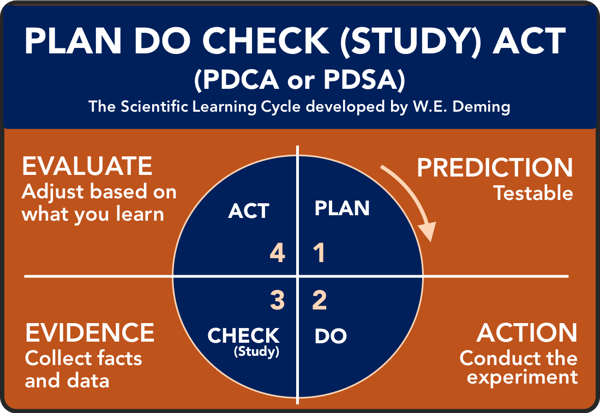

- Process: This involves the PDCA (Plan-Do-Check-Act) cycle. Teams plan an approach, implement changes (do), monitor the results (check), and based on observations, refine their approach (act). This cycle is repeated until the target condition is achieved.

- Outcome: Continuous, incremental improvements that move the organization closer to its target condition, with learnings gleaned from each cycle.

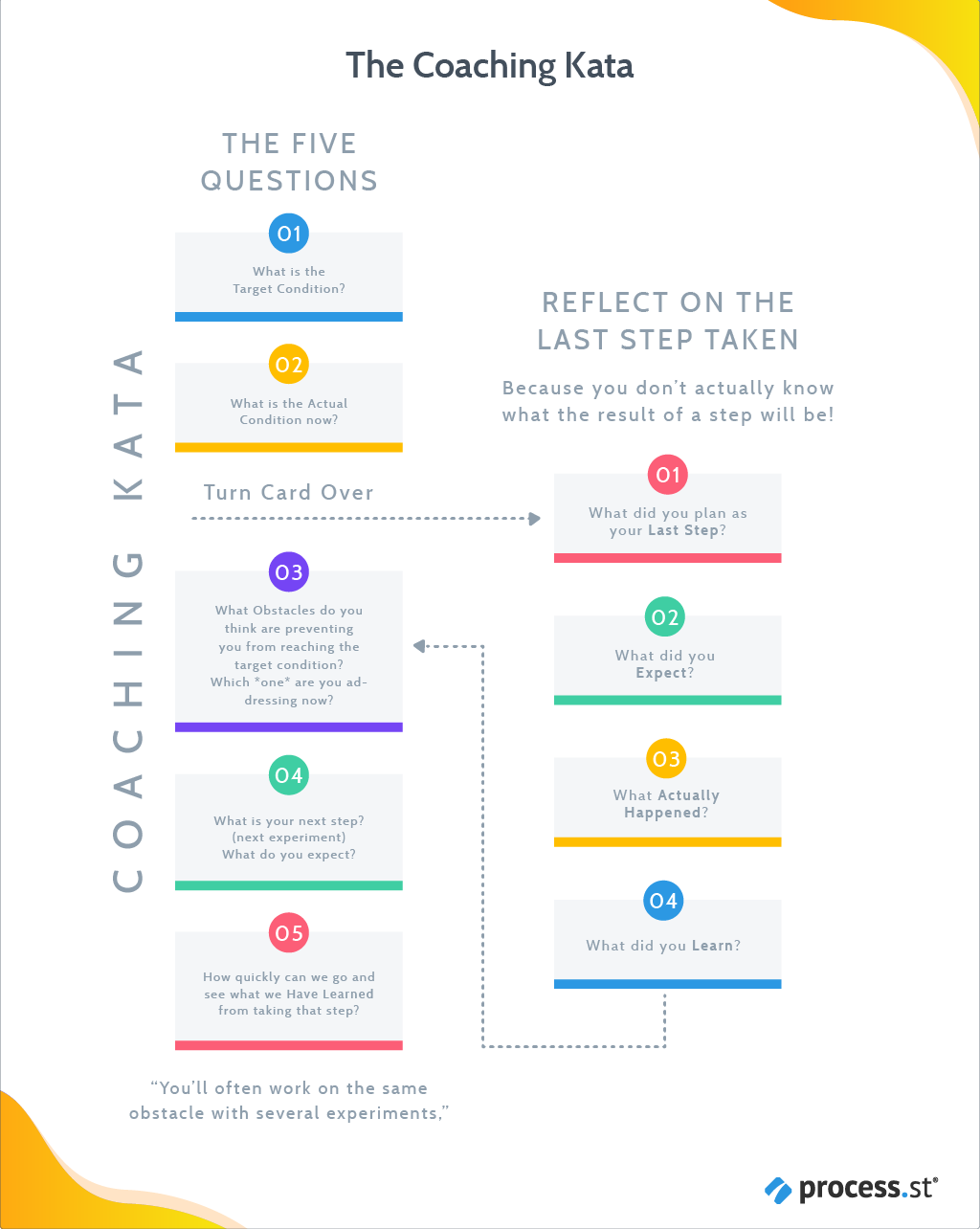

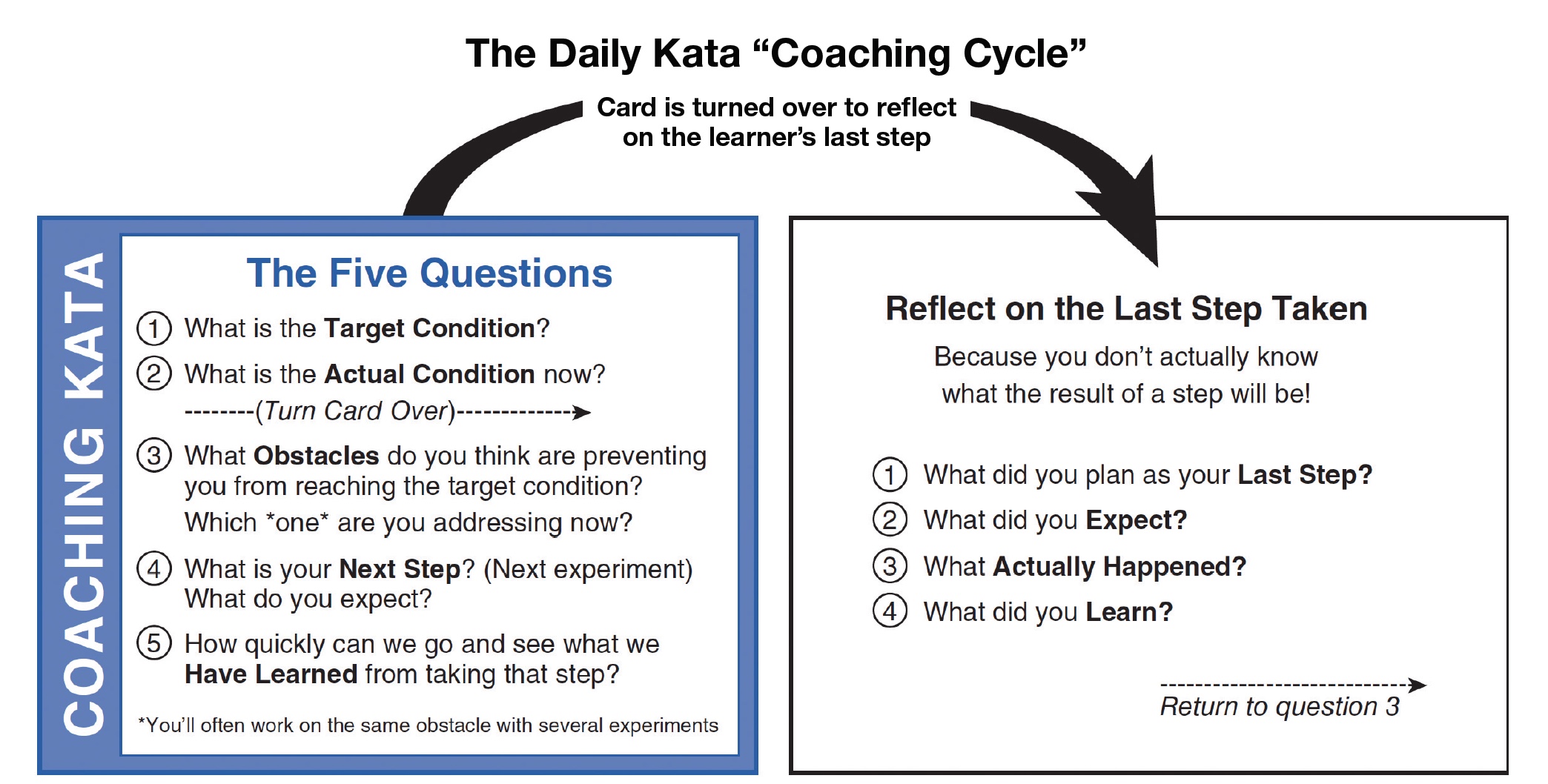

The Coaching Kata Process

While the Improvement Kata offers a structured pathway to achieve continuous progress, the Coaching Kata serves as its nurturing counterpart, ensuring that the journey is steered correctly. This mentor-mentee dynamic is pivotal in embedding the principles of continuous improvement deeply within the organizational fabric. Here’s a detailed breakdown of the Coaching Kata process:

The Learner Presents :

- Significance: For coaching to be effective, the starting point is a clear articulation of the situation by the learner. This lays the groundwork for the coaching session.

- Process: The learner presents a comprehensive overview of the challenge they’re facing, the current state of affairs, the desired target condition, identified obstacles, and their proposed next steps. This ensures that both the coach and the learner have a shared understanding of the situation.

- Outcome : A mutual baseline understanding from which the coaching session can progress. It also helps the coach gauge the learner’s current grasp of the situation.

The Coach Asks Guiding Questions :

- Significance: The essence of Coaching Kata isn’t to provide direct answers but to guide the learner to discover the answers themselves. This is achieved through probing, open-ended questions.

- Process: The coach poses a series of questions, each designed to stimulate critical thinking and self-reflection. Questions like “What is your target condition?” make the learner articulate and reaffirm their understanding. Meanwhile, queries like “What obstacles are preventing you from reaching the target condition?” push the learner to introspect and identify challenges.

- Outcome : The learner not only gains clarity on their situation but also develops the habit of structured problem-solving. They’re equipped to address similar challenges independently in the future.

Feedback and Reflection :

- Significance : Feedback is the bedrock of growth. While the guiding questions help the learner think, feedback ensures they’re aligned with the best practices and are aware of potential areas of improvement.

- Process : After the discussion, the coach provides constructive feedback. This can include validation of the learner’s approach, suggestions for alternative methods, or insights into potential pitfalls. The learner, in turn, reflects upon this feedback, understanding its implications and planning how to incorporate it.

- Outcome : A more refined approach to the challenge at hand. The learner not only gains a better understanding of their situation but also imbibes lessons that are valuable for future challenges.

Kata in Lean management represents a crucial paradigm shift, guiding organizations towards a culture of continuous improvement and operational efficiency. By instilling structured problem-solving routines and skill development through the Improvement Kata, and nurturing a mentor-mentee dynamic in the Coaching Kata, it ensures sustainable success.

The Improvement Kata’s four-step process (understanding direction, grasping current conditions, establishing target conditions, and experimenting towards these targets) combined with the Coaching Kata’s learner-centered approach, creates a robust framework. This framework not only addresses immediate challenges but also fosters a long-term mindset shift in teams and individuals, crucial for thriving in today’s dynamic business landscape.

- Liker, J. and Rother, M., 2011. Why lean programs fail. Lean enterprise institute , 2011 , pp.45-79.

- Villalba-Diez, J., Ordieres-Meré, J. and Rubio-Valdehita, S., 2016. Lean Learning Patterns .(CPD) nA vs. KATA. Procedia CIRP , 54 , pp.147-151.

- Ferenhof, H.A., Da Cunha, A.H., Bonamigo, A. and Forcellini, F.A., 2018. Toyota Kata as a KM solution to the inhibitors of implementing lean service in service companies. VINE Journal of Information and Knowledge Management Systems , 48 (3), pp.404-426.

Q: What exactly is "Kata" in the context of Lean management?

A: In Lean management, “Kata” refers to structured routines that teams and individuals adopt to improve their work and tackle challenges. Derived from the Japanese term for “form,” it emphasizes consistent practice and habit formation to foster continuous improvement and systematic problem-solving.

Q: How does the Improvement Kata differ from the Coaching Kata?

A: The Improvement Kata is a systematic approach focused on achieving specific targets or goals through understanding the current condition and making iterative changes towards the desired state. On the other hand, the Coaching Kata is a mentor-mentee interaction where the mentor guides the learner using structured questions, ensuring they’re correctly applying the principles of the Improvement Kata.

Q: Why is repetition emphasized in Kata?

A: Repetition is pivotal in Kata because consistent practice leads to habit formation. By repeatedly applying the principles of Kata, individuals and teams develop an instinctive ability for problem-solving and continuous improvement. Over time, this results in enhanced efficiency and a proactive approach to challenges.

Q: Can Kata be applied to any organization or industry?

A: Yes, the principles of Kata are versatile and can be adapted to any organization or industry. While it originated in manufacturing, its core tenets of continuous improvement, structured problem-solving, and mentorship are universally applicable, making it relevant for diverse sectors and business challenges.

Q: How does one ensure effective implementation of Kata in an organization?

A: Effective implementation of Kata requires commitment from leadership, proper training for both mentors and learners, and regular practice. Starting with a pilot team or process can be beneficial. Over time, as the organization witnesses the benefits of Kata, it can be scaled up, with success stories serving as catalysts for wider adoption.

Daniel Croft

Hi im Daniel continuous improvement manager with a Black Belt in Lean Six Sigma and over 10 years of real-world experience across a range sectors, I have a passion for optimizing processes and creating a culture of efficiency. I wanted to create Learn Lean Sigma to be a platform dedicated to Lean Six Sigma and process improvement insights and provide all the guides, tools, techniques and templates I looked for in one place as someone new to the world of Lean Six Sigma and Continuous improvement.

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Was this helpful?

The Lean Post / Articles / The Fundamentals of Improvement and Coaching Kata

The Fundamentals of Improvement and Coaching Kata

By Lean Leaper

February 28, 2022

Whether you're a veteran needing a refresh or a beginner requiring the basics, this round-up offers guidance that will strengthen your kata practice.

This selection of Lean Posts provides vital information that will help you practice these essential problem-solving and innovation-driving routines — and make the plan-do-check-act ( PDCA ) process a habit for everyone in your organization.

- Carrington on Kata In this 17-minute video, LEI Instructor Beth Carrington describes how practicing the Improvement and Coaching Kata routines help you align your organization, make innovation (large and small) happen at every level, and ensure that teams work toward goals in a systematic, scientific way.

- What Too Many Leaders Get Wrong with Coaching Kata Think you can dive headfirst into Coaching Kata with your direct reports? Think again. Learn what to avoid or stop doing, so you can perfect your practice.

- 5 Common Signs of a Novice Kata Practice Using an example from healthcare, Beth points out the common themes (aka mistakes) that many Improvement and Coaching Kata rookies make during their early efforts.

- Building a Learning Organization with Kata Baptist Memorial Hospital uses kata to build an “army of problem solvers.” In this video case study, Skip Steward, the hospital’s vice president and chief improvement officer, describes the “meta-routine” they follow and the results they’ve achieved.

- A Video Primer on Improvement and Coaching Kata In less than five minutes, Beth describes how to use these two vital problem-solving and innovation-driving practices, explaining how supervisors who consistently practice the Coaching Kata help team members practice the Improvement Kata. In turn, she demonstrates how the Improvement Kata guides team members to improve and innovate their work processes — and contribute to the organization achieving its top-level business objectives. She also emphasizes how the Improvement Kata and Coaching Kata establish a plan-do-check-act (PDCA) problem-solving culture through consistent, one-on-one interactions between managers and team members.

- A Video Primer Visualizing the Improvement Kata as a Funnel In less than two minutes, using a visual model, Beth describes the four routines of the Improvement Kata practice — and how the Improvement and Coaching Kata help supervisors guide their team members to connect top-level strategic objectives to their frontline work. She emphasizes how the supervisor coaches team members to break down the business goals into personal mid-term and short-term challenges, which they can then achieve through experimentation using the plan-do-check-act (PDCA) process.

Improvement Kata/Coaching Kata

Develop Scientific Thinking, a Foundation of Lean Management in the 21st Century.

Written by:

About Lean Leaper

I want to know more about kata

Leave a Comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

A New Era of Jidoka: How ChatGPT Could Alter the Relationship between Machines, Humans, and their Minds

Article by Matthew Savas

Ask Art: Why is a Lean Sensei Necessary?

Article by Art Byrne

Developing Products is a Team Sport

Article by Lean Leaper

Related books

The Power of Process – A Story of Innovative Lean Process Development

by Eric Ethington and Matt Zayko

The Gold Mine (Audio CD)

by Freddy Ballé and Michael Ballé

Related events

Online – On-Demand, Self-Paced

Kaizen Bundle

Lean fundamentals bundle, explore topics.

Privacy Overview

What is Kata?

Empowering excellence through incremental, continuous improvement., free download, starter kata kit.

Familiar with Kata and ready to get started? Download this kit of instructions and templates.

Kata Defined

Toyota kata, kata in lean, kata methodology, improvement kata, coaching kata.

Kata: Structured practice for consistent improvement.

Originating in martial arts, "kata" are structured routines consisting of patterns. Whether in martial arts, personal improvement, or business, Kata as we discuss it is a methodology that uses repeated, consistent practice and scientific thinking to train the skills that enable a person to make rapid, incremental improvements every day.

The suffix "kata" means "way of doing" — common definitions are:

- Way of doing something

- Pattern, form, routine, or method

- Training drill

All of the definitions of kata essentially refer to the same basic concept — a form, routine, or pattern of behavior that can be practiced to develop a skill to the point where it becomes second nature.

Practicing kata (patterns) consistently and deliberately forms a habit. Forming a habit develops new skills. With new skills comes increased confidence in one's abilities to recognize and make small improvements that keep a person (or a process) in top form continuously.

As simple as it sounds, Kata involves deliberate, repetitive practice to master. In martial arts, kata is choreographed patterns of movement that are practiced until mastery of a single form is achieved. The practice is applied again and again to learn and eventually master each small set of movements.

In business, Kata describes the foundational continuous improvement philosophy and culture exemplified by Toyota. By implementing Kata, your organization can develop the habits and skills to shift individual mindsets and the corporate culture toward truly continuous improvement that keeps processes efficient, customers happy, and companies profitable.

A Complete Pillar Strategy Guide

Everything you need to start creating your pillar page flows today.

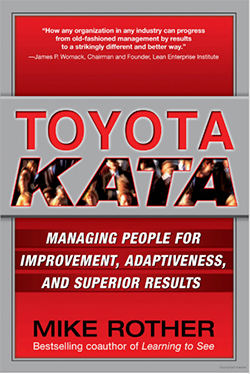

Toyota Kata Summary

"Toyota Kata" is the term that Mike Rother (internationally recognized Lean guru and author of Learning to See ) coined to help American manufacturers mirror Toyota's successful practices of true continuous improvement.

"Through the adjustment of what is learned along the way, Toyota advances as a scientist would. With each new empirical observation, the scientist adjusts the course to take advantage of what he has learned. I learn every day what I need to know to do tomorrow's work." ~Mike Rother from the book Toyota Kata: Managing People for Improvement, Adaptiveness and Superior Results

Past observations of Toyota’s operations educated American manufacturers on the innovative company’s methods for improving process efficiency and eliminating waste (the traditional “Lean Tools”).

Decades later, however, the same observers were shocked that when they observed the same Toyota operations, they now saw different solutions to the same processes. Rather than implementing a one-time “Lean Tool” solution, Toyota continued to adapt, improving its processes over time.

Toyota Kata and Mike Rother's Research

After studying Toyota’s production methods years earlier, Rother and others realized that while many companies knew a lot about Toyota, they were struggling to implement their successful methods. So, they went back to learn more.

In visiting Toyota again, Rother describes how the Toyota managers and executives helped the group realize that the questions they should be asking were not about the current tools Toyota is using to solve Toyota’s current problems, but rather what methodology they are employing to build the organizational skills to address all challenges over time.

Toyota is, of course, focused on its own long-term survival as a profitable organization. Rother recognized that to ensure long-term success, they had developed “consistent routines of Leadership and Management that help maintain an entrepreneurial spirit in the organization.”

By developing an organizational mindset where every employee is educated and empowered to make improvements constantly, the success of the company continues despite changes in company structure and leadership over time. Rather than having the typical “entrepreneurial phase” that most companies grow through and then settle into maintaining the status quo, Toyota created a lasting entrepreneurial culture .

Toyota Kata Fundamentals

Studying Toyota again from 2004-2009, Rother now focused on learning HOW the company developed solutions rather than the specifics of the solutions. To do this, he focused on two key questions:

- What are the unseen managerial routines and thinking that lie behind Toyota’s success with continuous improvement and adaptation? (Why can they keep going and sustain this where others struggle?)

- How can other companies develop similar routines and thinking in their organizations?

The Unseen Routines Behind Toyota’s Success: The Improvement Kata and the Coaching Kata

During the Toyota research, the group recognized that the Toyota managers’ approach to problem-solving is a scientific pattern of thinking and behavior. In his Toyota Kata book, Rother outlined this scientific approach as a four-step model they dubbed the “ Improvement Kata. ”

Rother describes that while every manager has their own way of implementing it, the pattern generally follows these four steps:

- Get the direction or challenge : Understand the sense of direction, the larger, likely time-distant vision, and be clear on what that is.

- Grasp the current condition : Examine where you are now and be able to define the current situation factually and clearly.

- Establish the next target condition : Determine a good next-step goal that will stretch the edges of current knowledge and capabilities, move toward the challenge, and will be accomplished by a certain date.

- Conduct experiments : Experiment methodically and scientifically to get to the next target condition.

Establishing the “Next Target Condition” allows for iterative experimentation and learning without the necessity of every next step needing to be “right.” The “fear of failure” that comes from needing every step along the way to be correct condemns you to only taking steps that are certain to succeed. This limiting mindset severely limits the capability for improvement and innovation. Having an entrepreneurial mindset means having the willingness to take calculated risks.

None of this is revolutionary thinking. This Toyota method that Mike Rother observed and termed the Improvement Kata bears a striking resemblance similar to other models of the creative process. Creative process models are similar in that they all reflect the questions that humans ask when they are working to create:

- What are we trying to accomplish?

- Where are we now?

- What happened when we tried something new?

- What do we need to change or adjust to get to the next goal?

So, what is important to remember, in the words of Rother, is,

“It’s not about Toyota; it’s about humans.”

Rother called this model the Improvement Kata because it’s based on the Japanese word “Kata” or “way of doing” and this is the way of doing improvement. This is combined with the “way of coaching” or way of teaching that he calls the Coaching Kata . The Coaching Kata is a master-apprentice approach to teaching like what is used in training in sports or in music instruction. The coach gives input on what is being practiced, corrects as they practice, and the learner continues to practice with the new input.

Put together, the Improvement Kata and the Coaching Kata create a management approach for creating a shared way of thinking and working, a way that is not specific to a certain problem, situation, or environment.

This capability is a “Meta Skill,” an overarching skill that can be used to work on virtually any challenge, problem, or objective. By teaching a “content-neutral” meta-skill, the organization now has the organization-wide skill set to address challenges as they arise with a shared way of thinking and acting to improve and innovate continuously.

This culture of true continuous improvement is what keeps Toyota at the forefront of manufacturing excellence. The Kata enables improving every process every day. It’s not limited to management or customer-facing employees. Every employee from top management to janitors is trained to and expected to encourage daily improvements through their own actions. Practicing the Improvement Kata and the Coaching Kata will develop a habit that, over time, changes behavior, which ultimately changes culture.

In Kata, it is everyone's responsibility to encourage daily improvements through their actions.

Who Uses Kata?

Anyone who wants to develop the habit and skills of continuously improving daily actions can use Kata. Various manufacturing industries utilize the Kata methodology. Although Toyota Kata was developed to emulate Toyota’s Manufacturing culture, like the Lean Tools, it easily adapts to non-manufacturing industries. The Healthcare industry quickly embraced and has advanced using the Kata methodology. Agile Software Development can also use Kata for Agile Retrospectives. The opportunity exists to deploy Kata for startup businesses to drive progress and accountability.

What Type of Process Will Kata Work On?

Kata is a methodology that, with proper training and practice, will develop the habit, the skills, and eventually the culture/mindset of continuous improvement. As such, Kata can work on any service, any sport, and any process. (Hint: Check out the kata example at " Strive Fore Five ".)

What is Kata in Lean?

The Kata model builds scientific-thinking skills that, when practiced, will make every learner a better problem-solver.

In terms of Lean, Kata is the problem-solving methodology of creating incremental, continuous improvement by repeating a four-step routine that teaches and facilitates a logical approach to problem-solving.

Kata develops new skills

A “kata” is a set of practices that help develop a new habit or skill. A Kata Learner works through a set of practice routines and reviews with a Kata Coach what has been done, what has been learned, and what are next steps.

Throughout the process, small, incremental changes are made and tested, and learning is incorporated into working toward the larger vision or challenge. This practice is most commonly discussed as kata in martial arts (the term “kata” is of Japanese origin) but is easily observed in many sports, music, and other areas where a “learner” works with a “coach” to improve a skill.

Kata supports Lean

In the world of Lean, the Improvement Kata and the Coaching Kata combine to form a similarly powerful method for building skills of problem-solving.

Kata doesn’t compete with but supports and strengthens the effectiveness of Lean Six Sigma tools and techniques such as:

- Value Stream Mapping

- Standard Work

- Kanban, and so on.

It is a way of training and supporting the members of an organization in approaching problem-solving using scientific thinking. As such, Kata can be applied to increase the effectiveness of any of the Lean Six Sigma tools or techniques by grounding it in logical, scientific thinking that delivers rational, provable results.

Approaching problems in business scientifically allows us to come to well-reasoned, logical solutions and discuss them effectively with others by being able to demonstrate precisely how the solutions were tested and evaluated again relevant criteria.

The Improvement Kata directly incorporates the scientific problem-solving method of Plan, Do, Check, Act (PDCA)–or as it is sometimes known, Plan, Do, Study, Act (PDSA)–to make continuous improvement a daily routine or habit.

What is critical in any discussion of kata, whether sports, music, or Lean Six Sigma, is that it is not something that can be simply shown, it must be done (and practiced).

A3 Problem-Solving and Toyota Kata

Take the A3, for example, a common tool observed in use at Toyota and one that many individuals and organizations struggle to use effectively. Implemented in isolation, the A3 is a tool for tracking and reporting problem-solving process results in a concise format.

Without mentoring from an experienced A3 coach, any biases, missing knowledge, and incorrect assumptions made by the reporter may be not only reported but incorporated in the eventual implementation.

Used properly, however, the A3 is more than simply a report. It is a living document that evolves through the problem-solving process of examining, planning, building consensus, implementing, and evaluating the results (before starting again as many times as needed).

The A3 isn’t created and implemented in isolation but as a tool for:

- systematically thinking and working through a challenge,

- communicating about it with a manager or “coach” (remember, the A3 is a summary of a problem-solving process), and

- striving to develop ideas and solutions based on actual facts and data.

This is the same purpose as the Improvement Kata / Coaching Kata.

The value of adding the practice routines of the Improvement Kata + Coaching Kata is that the problem-solving process becomes clearer and more systematized. By adhering to the kata routines of deliberate Improvement and consistent Coaching, the A3 process becomes a practice in teachable, foundational skills of the scientific process that can be applied to any tool, technique, or process. This creates both a shared way of thinking and communicating and facilitates the confidence that the effort and resources put into the problem-solving method will support rational, well-tested conclusions that can be verified and trusted.

You can not implement Kata. You can only practice a Kata to develop a skill. Kata will not replace your current improvement methods — it will support them.

How Practicing Kata Can Improve Your Use of Lean Six Sigma Tools & Techniques

Kata Methodology Overview

The Kata model is grounded in the philosophy that teaching workers (or in kata, learners ) to think and act scientifically, we can build a culture where every employee is educated and empowered to be a better problem-solver.

Rather than specialized staff members executing one-off, resource-intensive “improvement projects,” practicing the Kata helps every member of an organization become skilled in seeking improvement every day.

The Kata consists of the Improvement Kata (IK) and the Coaching Kata (CK) , which form a structured pattern for making small incremental improvements every day.

The Improvement Kata is a model of the human creative process. It’s a four-step pattern of establishing target conditions and then working iteratively (scientifically) through obstacles by learning from them and adapting based on what's being learned.

The Coaching Kata is a pattern for managers to follow in teaching the Improvement Kata pattern in daily work, so that it becomes part of an organization's culture.

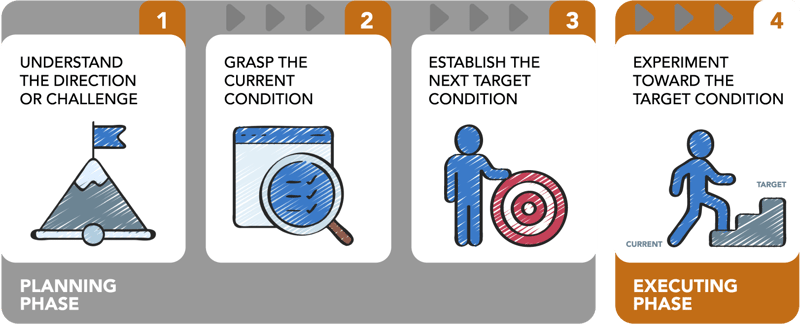

Kata Planning Phase

During the Planning phase of the Kata, the Kata Coach “plans” the upcoming Coaching Cycles while the Learner works through Steps 1 – 3 of the Improvement Kata:

- Understand the Direction or Challenge: What is the future, management-defined vision for where we want to be?

- Grasp the Current Condition: Where are we now (processes, metrics)?

- Establish the Next Target Condition: What is our next interim step toward the Direction, something that should stretch our current knowledge and capabilities but be achievable in a few weeks to a few months time frame?

Kata Executing Phase

During the Executing phase, the Learner performs small, rapid experiments using the Plan-Do-Check-Act format to iterate toward the Target Condition. The Kata Coach executes “Coaching Cycles” with the Learner, supporting and guiding the systematic analysis and learning from their experiments.

As the Learner goes through each cycle, rapidly experimenting on the path of discovery, the threshold of knowledge moves toward the Target Condition and, ultimately, toward the Direction/Challenge. The entire process is practiced systematically – planned and executed logically and scientifically.

Practicing the Kata as a consistent activity can help build a culture of true continuous improvement by teaching and empowering employees to be better, proactive problem-solvers.

What’s Wrong with What We Do Now?

Traditional implementation of Lean continuous improvement methodologies can often be reactive — more “symptomatic” than scientific.

- Hunting for waste or opportunities (never say “no” to a good problem)

- Troubleshooting to eliminate existing problems (scattershot approach that may not achieve meaningful improvement that moves the organization forward)

- Requires special people with special training (so the majority of the organization does not feel involved in continuous improvement)

- Project-based (narrow focus that can miss bigger issues)

- Long learning cycles (management, budget changes, staff turnovers can stop an effort before it produces anything) Focused on specific tools and methods

Traditional methods often focus heavily on planning to work through an issue.

- Brainstorm a list of root causes

- Brainstorm a list of solutions

- Vote on the best solutions

- Create and implement an action plan

- And, hope for the best

The focus becomes getting the action plan created and implemented rather than on solving the problem. Unfortunately, this often results in poor use of an organization's limited capacity and resources for making improvements.

Things change.

In any dynamic environment or complex system, factors frequently arise that make the path forward unpredictable and non-linear. As you move forward with implementing the predetermined plan,

- The situation changes

- New information arises

- Things are learned

For improvement efforts to succeed and be sustainable, it is critical that the process be flexible enough to incorporate changes and new information.

If your methodology is not flexible enough to incorporate new learning, how can it possibly succeed? To be more effective, we must plan to manage uncertainty, empowering flexible learning and innovation at every step. This is where Kata shines.

Practicing Kata for Real Continuous Improvement

How can we do it better scientific thinking..

What they discovered is that Toyota still uses the Lean tools and techniques that were observed decades before, addressing issues associated with quality, cost, and delivery with tools such as:

- Value Stream Maps

- Visual Management

- Empowerment

However, the real strength of Toyota’s approach is something else entirely — a systematic, scientific way of thinking and working that managers teach throughout the organization. This is what Rother termed the “Improvement Kata” and the “Coaching Kata.”

The Kata provides a framework, a foundation for that makes using Lean tools and techniques work better and keep working. It supports any improvement method by creating a shared way of thinking and building the skills for scientific thinking.

What is Scientific Thinking?

Scientific thinking is a routine of intentional coordination between

- what we predict will happen (theory)

- what we observe actually happens (evidence),

- and adjusting based on what we learn from the difference.

Since the path to a challenge or goal cannot be predicted precisely, we use scientific thinking – experimentation – to advance our “Threshold of Knowledge” incrementally by testing, learning, and adapting based on what we learned.

Our Threshold of Knowledge is the point at which we have no facts or data – the limit of what we currently know. It is at the edge of this uncertainty that we begin to learn. With each experiment, we learn new information that is incorporated and moves our threshold of knowledge further toward our goal, our “next target condition.”

Establishing a big “right” (rigid) plan can be costly, consuming many resources, and likely to fall apart when faced with unanticipated (but almost inevitable) factors.

Practicing scientific thinking keeps us in the adaptive (flexible) mode of iterating forward as quickly and inexpensively as possible, experimenting to confirm or refute our hypotheses, and learning from the results either way.

Plan-Do-Check-Act: A Model for Scientific Thinking

Based on the work of W. Edwards Deming in the 1950s, Plan-Do-Check-Act, or PDCA as it is commonly known, (also called the Deming Cycle or Deming Wheel or Plan-Do-Study-Act, PDSA), is an improvement cycle model based on the scientific method.

PDCA Four Steps:

- PLAN: Define what to do next and what is expected. Establish targets, metrics, goals and determine potential changes needed to reach the goal, the Target Condition.

- DO: Implement, test the prediction by taking the next steps according to the plan.

- CHECK: Observe what happens. Analyze and measure the results of the implementation.

- ACT (or ADJUST): Evaluate the results and compare what actually happened to what was predicted. Take next action based on the results: Standardize what worked as expected, or adjust and improve based on what is learned and begin the PDCA cycle again.

Important Notes about PDCA:

Pdca isn’t about implementing solutions.

Not every step taken will bring a measurable benefit of its own. Using the PDCA cycle is about learning what will be needed to reach the Target Condition. Going through the scientific process and gaining information that moves toward the Target Condition (which is measurable and has an “achieve-by” date) is where the value lies. Small, rapid experiments advance knowledge quickly.

Failure is Important

As discussed earlier, the path to the Target Condition will not be a straight line. Failed experiments, refuted hypotheses, are an important part of the process. When a result matches what was predicted, the hypothesis is confirmed. However, when a hypothesis is disproven, beliefs are challenged, new insights are discovered, and new knowledge is created. Though it can seem counter-intuitive, small failures in rapid experiments provide opportunities for learning and progress toward the Target Condition.

Frequent, Rapid Experiments are Best

Since most learning happens when hypotheses are disproven, conducting quick, inexpensive, and frequent (ideally daily) experiments is ideal. Rapid, frequent PDCA cycles provide more learning and, therefore, more opportunities for adaptation and innovation. Whenever possible, it’s best to experiment at the process level (rather than the value stream or organization levels) since there are fewer variables (more specific information is available rather than macro-level conjectures) and adjustments can happen more quickly and less expensively.

Why Do We Need to Practice Scientific Thinking?

Scientific thinking is a skill. Like any skill, the best (and really the only) way to learn it is to … PRACTICE. Scientific thinking is not our default mode as adults. Just like in sports and music, we have to learn how to do it and practice it until it becomes a new habit.

Neuroscience teaches us that our thinking patterns become set with repetition. Our patterns of thinking and acting build neural pathways in our brains. It’s a fast and efficient way for our brains to handle repetitive functions so that they require little attention or energy. For actions that are repeated often, those pathways become superhighways.

Each time we think something or do something a certain way, we are more likely to think or do the same thing again.

This is why learning something new often feels slow, awkward, and inefficient. Instead of speeding down a superhighway, we’re slogging through new territory, tripping over weeds and trying to find our way. It can feel difficult or even wrong, and we often want to avoid it.

This is also the power of creating a new, beneficial habit. Learning does require attention and energy until we have done it enough that we have created a new pathway. However, once the new habit is established — such as the habit of thinking scientifically about how to approach challenges — it becomes the more efficient and effective pathway.

This is the basis of the Improvement Kata Methodology: Scientific Thinking Pattern + Techniques of Deliberate Practice

The Starter Kata: The Starting Point

The simple practice routines for each step of the Improvement Kata model are the basic repertoire of the methodology. Like learning basic dance steps, piano scales, or guitar chords, the Starter Kata are the foundational practice routines of the Improvement Kata + Coaching Kata. Practicing these routines will help develop the scientific mindset .

Start by Practicing Fundamental Skills

The Five Questions of the Coaching Kata and the PDCA cycles of the Improvement Kata are used together in daily Coaching Cycles at the Learner’s Storyboard. The two routines are used to teach and facilitate systematic and effective experimentation.

As the Starter Kata routines are practiced, the learner creates new habits and ways of thinking and acting which, with continued practice, become new problem-solving skills. Beginners should follow the Kata exactly without deviation so that the Learner can internalize the patterns.

With increasing proficiency, Learners (and Kata Coaches) can start to develop their own style (within limits, of course). Likewise, over time, organizations can evolve their Kata practices to suit their specific culture.

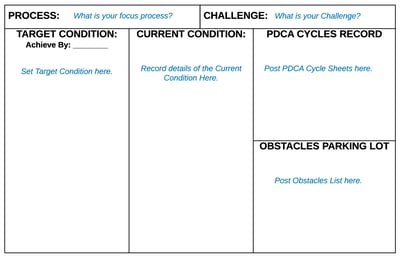

Kata Learner's Storyboard

The learner's storyboard is a template that brings together all of the information from the Improvement Kata. The layout follows the pattern of the Five Questions of the Coaching Kata so that the document provides a framework for the coaching cycles. Learner's Storyboard layout for the Improvement Kata (Toyota Kata) consolidates information and provides a framework reference for the coaching cycles

- Challenge: State the vision. This can be 6-month to 3-year goal, typically established by upper management.

- Current Condition: Establish and record the current state of the focus process with facts and metrics.

- Target Condition: Determine and state the next target condition, the desired condition of a process we strive to achieve in 1 -4 weeks. (Establishing a target condition allows measurable results to be achieved faster than random improvements.)

- Obstacles: Generate a list of possible items that are preventing us from being at the Target Condition right now. Experiment cycles will focus on one Obstacle at a time.

- Experiment Cycles: Record the activity and results of each experiment, the Plan-Do-Check-Act (PDCA) cycles.

Important points to reiterate about the Kata Methodology

- The Improvement Kata + the Coaching Kata is not a tool by itself. The Kata practice routines will make the learner a better problem-solver able to use any tool more successfully.

- Kata cannot be “implemented.” Like any fundamental skill-building routine, a Kata can only be practiced to build mastery.

- Kata does not replace other continuous improvement methods — it supports them.

Four steps to developing the fundamental skills of scientific thinking, experimenting toward a goal instead of deciding the "right" way forward ahead of time. Working consistently and quickly to test incremental improvements creates a culture of continuous improvement that also accommodates changes and uncertainty.

The Improvement Kata (IK)

The Improvement Kata is a four-step routine that, when practiced, can build a habit of thinking and working creatively and scientifically to build a culture of improvement and innovation in an organization.

A model of the human creative process, the Improvement Kata provides a pattern for scientifically and systematically working through obstacles toward a goal (target condition). Rather than randomly seeking opportunities for improvement or causes for problems, with the Improvement Kata, we strive toward the next target condition through iterative learning—conducting small, rapid experiments to advance our knowledge quickly.

A “meta-skill,” the Improvement Kata provides a framework in which any Lean Six Sigma tool or technique can be implemented more effectively. Practiced consistently, it becomes a habit and helps create an over-arching mindset and culture wherein true continuous improvement becomes possible.

The Four Steps of Improvement Kata

- STEP 1: Understand the Direction or Challenge

- STEP 2: Grasp the Current Condition

- STEP 3: Establish the Next Target Condition

- STEP 4: Experiment Towards the Target Condition (PDCA)

The steps of the Improvement Kata pattern are carried out by the Learner (mentee) who systematically plans, establishes target conditions, and then conducts experiments (PDCA) to work through obstacles and learn from them in the process of improving. The Learner is supported by a Kata Coach (mentor) who teaches them by conducting Coaching Cycles using the Five Questions of the Coaching Kata.

The first three steps comprise the Planning Phase of the Improvement Kata. In this phase, we answer the critical question, “Where do we want to go?”

“Planning” in this model is not about planning actions, but about gaining understanding and perspective that provides the foundation for the Executing Phase. It’s critical to take time to analyze and understand Steps 1 through 3 to alleviate any biases or preconceptions before moving on to executing.

Let’s explore the 4 Steps of the Improvement Kata.

The first step of the Improvement Kata is to understand the Direction or Challenge. What vision are striving to meet?

Set at the leadership (organization or value-stream) level, the primary Direction or Challenge starts with an over-arching strategic vision that relates to better serving the customer. The Challenge is defined as specific quantifiable, numeric targets and a quantifiable, visual description that are planned to be achieved in the future, typically one to three years out.

To establish an effective Challenge, it may be necessary to grasp the larger Current Condition first using Gemba Walks, Value-Stream Mapping, and/or Voice of the Customer (VOC) processes. A future-state value stream map can clarify the vision and provide an effective basis for the Challenge.

The over-arching Challenge provides a cohesive objective for process improvement efforts throughout the organization. This “big-picture” vision is vital so that all of the targets set at each level down through the organization or system are recognized as meaningful contributions to a larger purpose.

However, this vision is not an effective means of directing daily efforts since it is too vague and far into the future.

The Challenge gets broken down into successively smaller goals as it flows down the organizational structure. At the individual process level, the Challenge becomes the Target Condition from the next level above. From the largest Challenge to the individual process level, all link to the strategic goal that is related to better serving the customer.

Now that we are clear on the Challenge or Direction coming from above, we need to have a clear picture of where we are now, our Current Condition . What is the current way of operating? What is our starting point?

Grasping the Current Condition requires a thorough process analysis—getting immersed in the process to understand in detail how it currently operates and how it is currently performing. This step is the critical prerequisite to setting the next Target Condition. We have to know where we are before we can establish where we want to be.

Steps to clearly define THE Current Condition:

- Go to Gemba – walk the process (this is where Value-Stream Mapping comes in)

- Query the experts (workers)

- Quality, Speed, Flow, Simplicity

- Capture what is happening

- Use your Kata Coach

- Review the Current Condition on paper using the visual tool of the Kata Storyboard

Going through these steps deliberately and engaging with a Kata Coach will help the Learner see beyond their own biases and preconceptions during the process analysis. Stay with the Current Condition analysis until it is clear you have reached your Threshold of Knowledge about this process and the next Target Condition becomes apparent.

Now that we are clear on the Challenge and on our Current Condition, the next step is to establish the next Target Condition. What is a next step in our way of operating that will move us toward the Challenge?

One of the most important components of practicing the Improvement Kata successfully is understanding how to set appropriately challenging but achievable Target Conditions.

The purpose of studying the Current Condition so thoroughly is to gather the information and data needed to establish a clear and measurable Target Condition for this process that moves in the direction of the Challenge:

- Outcome metric: Desired outcome performance of the process

- Pattern of Operating: Describe how you want the process to be operating by the achieve-by date of the Target Condition

- Process metric: At what rate do you want a task to happen?

The next Target Condition will:

- lie beyond your current Threshold of Knowledge,

- have a specific “Achieve-by” date, typically one week to three months in the future, and

- describe with some detail how the process should be functioning when the Target Condition is achieved.

Once the Target Condition is clearly defined, Obstacles to moving from the Current Condition to this new state will become apparent and should be recorded in an “Obstacles Parking Lot.” These will become the basis of the experiments conducted in the Executing Phase. This list will continue to be updated throughout the Executing Phase as new Obstacles become apparent.

Five Steps to Establishing a Target Condition

- Review the Challenge

- Set the Target Condition achieve-by date

- Define the desired outcome performance

- Define the desired attributes

- Start the “Obstacles Parking Lot”

Reminders for Setting Appropriate Target Conditions

- Problem is defined clearly – Target – Actual – Gap

- Stretch Targets – establish Target Conditions that move beyond current knowledge (require stretch) but are not so large as to be unrealistic

- Improve and develop strong problem solvers

- Connected to Challenge (Direction), Process Metrics, and Results Metrics

Effective Obstacle Brainstorming

Creating the Obstacles list is fundamental to the Improvement Kata and to the PDCA process. After the Target Condition is set, the Learner(s) should brainstorm various issues that could hinder reaching the Target Condition and list these in the “Obstacles Parking Lot.” This becomes the list of items that form the basis for the PDCA / experimentation cycles. Important items to note about brainstorming the Obstacles list:

- Brainstorm multiple Obstacles to avoid focusing too narrowly

- State the Obstacles in terms of the Target Condition

- State the Obstacles as hindrances to reaching the Target Condition (not solutions)

- Address one Obstacle at a time—conduct small, rapid experiments, learning from results each cycle until the Obstacle is addressed, then move to the next

Steps 1, 2, and 3 are the Planning Phase of the Improvement Kata. Step 4 is the Executing Phase, the “How We Get There”. We now have our “learning zone.” This is the area of uncertainty between where we are now and where we’re trying to get to, and we’re seeking the most direct path through it. The way through will not be a straight line, but we will adjust frequently and quickly as we go through rapid learning cycles.

In Step 4, we “iterate” toward the Target Condition, executing experiments using a step-by-step process to work on Obstacles one at a time. Using the Plan-Do-Check-Act or PDCA [link to Methodology page], rapid, frequent (daily) experiments are conducted to test hypotheses and discover new information that will move us from where we are toward where we want to be next, the Target Condition. Though not every experiment will produce straightforward, linear “progress,” each will move out our Threshold of Knowledge.

Selecting an Obstacle for PDCA

Armed with the “Obstacles Parking Lot,” one Obstacle that seems to be preventing the process from operating in the way specified by the Target Condition is selected for experimentation. A couple of important things to note about Obstacles:

- Not all Obstacles will have been identified in the previous steps. New Obstacles may become apparent, and the Obstacles Parking Lot should be updated to reflect them.

- Always work on ONE Obstacle at a time. Introducing multiple variables complicates and slows the experimentation process making it difficult to achieve the rapid learning that advances the process quickly.

- Not every Obstacle needs your attention. Be sure to select Obstacles based on what needs to be improved, those that are actually hindering the process from working as specified by the Target Condition.

The achieve-by date sets an important boundary for this process. With only limited time each day and limited resources to apply in working toward the Target Condition, the achieve-by date helps keep our focus on what needs to be done rather than wanting into resource-sucking “everything we can do” territory.

Collecting and Analyzing Data Scientifically

As discussed in the Kata Methodology section, every experiment creates learning, including and especially the “failed” ones that disprove our hypothesis about what we expect to happen. While experiments will happen rapidly, this is because they will be small and clearly defined, not rushed. As always, safety first! In each PDCA cycle, the “Check” phase is crucial for learning. This is where discovery happens. Keeping an open mind to new mental models creates opportunities for adaptation and innovation.

Next: Repeat the Pattern!

Once the achieve-by date is reached (or the Target Condition is achieved), the Improvement Kata pattern is repeated. Before that happens, however, the Learner and the Kata Coach reflect on what was learned through the steps and the PDCA cycles. Having practiced and learned from the Improvement Kata, a new Threshold of Knowledge and a new Current Condition are established, and the Learner is ready to repeat the cycle.

Remember the Improvement Kata combines scientific steps and techniques of deliberate practice. While using the Improvement Kata to work systematically toward a strategic challenge, the value of repeatedly practicing the scientific approach is to develop effective problem-solving skills. And like any skill, mastery is only achieved through repeated, systematic practice.

Five-question process helps managers coach people in thinking and acting scientifically, focusing more on the people and less on the specific content. Consistent, repeated coaching of the basic steps helps people establish the desired habits and mindset of scientific thinking and acting when addressing any challenge.

Practicing the Coaching Kata (CK)

As a manager, ones primary responsibility in agile organizations is to help their people develop their capacity to meet challenges and adapt in a rapidly changing environment. Practicing the Improvement Kata develops the problem-solving skills to do just that. And Coaching Kata is how managers develop those skills in their people.

Coaching Kata Defined

Coaching Kata is quite simply a manager or mentor supporting the learning of the problem-solving method of the Improvement Kata (IK) by an employee or mentee.

The primary role of the individual Kata Coach is to ensure that the Learner follows the scientific method precisely during the Improvement Kata process and practices it consistently. Organizationally, it is the Coaching Kata that helps incorporate Kata mindset into the company culture.

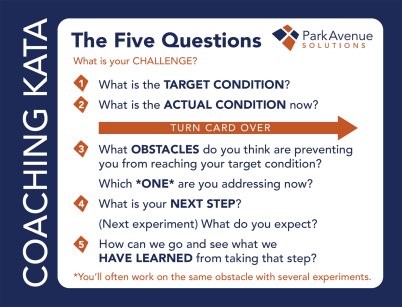

The foundation of the Coaching Kata is the “The Five Questions of Coaching Kata”. The questions are structured to provide a clear means for the Kata Coach to guide the Kata Learner deliberately and methodically through the improvement process toward the target condition.

THE FIVE QUESTIONS

- What is the target condition?

- What is the current state of the process?

- What obstacles are you working on now which prevent us from reaching the target?

- What is your next step? (PDCA cycle)?

- When we can see the result of this step?

The Coaching Kata Card below is a helpful tool for Kata Coaches. The card provides the framework for the Kata Coaching Cycles.

Click the button below to download a PDF with 4 printable Coaching Kata cards per page.

Why Coaching is Important in Kata

In his recent manual for the effective Kata practice, The Toyota Practice Guide [link to LAS sales page], author/guru Mike Rother explains:

“... a job description for an Improvement Kata coach, especially with beginner learners might be: To accompany the learner and give procedural guidance as needed to ensure that although the learner struggles, he or she is ultimately successful in learning to use the Improvement Kata pattern to achieve challenging, real target conditions.”

Simply knowing how to step through a process is not enough for good skill development (or for continuous improvement). Continued and deepening practice, learning from mistakes, celebrating successes, and not becoming complacent or overwhelmed are all vital components of mastering a new skill. Kata Coaching helps the Learner with all of these.

With the Improvement Kata, coaching can help ensure that the Learner,

- Is consistent and deliberate with practice

- Follows the pattern (Starter Kata) precisely as it is being learned

- Reviews and works to improve on mistakes

- Recognizes the value of both failures and successes

- Makes progress!

Like any good coach, a Kata Coach won’t do the work for the Learner … but they will plan the plays, teach the fundamentals, develop the skills, support and encourage the Learner, and take responsibility for ensuring their success.

Organizationally, Coaching Kata can help with the following:

- Teaching everyone in the organization the Improvement Kata and making Kata a part of the organizational culture

- Engage everyone in the improvement process (train them to use the Improvement Kata in their daily work)

- Identify needed skills improvement for individuals and use real-world problems to train

- Ensure that leaders have a strong grasp of the workplace at the process level

- Pass on the Improvement Kata to future employees and generations of leaders

Talk with a Kata Coach about how to get started

Coaching Cycles

Like the beginner Learner, a beginner Kata Coach will need to practice to build mastery of the coaching skills. The Coaching Kata provides a practice framework for this purpose.

Coaching cycles should be scheduled daily for approximately 20 minutes near the beginning of the workday. The Coach-Learner dialogue needs to take place in front of the Learner’s Storyboard, which should be near the focus process if at all possible. The “living document” of the Kata Storyboard is the ongoing record of the Learner’s work with the Improvement Kata. It documents the process and provides the framework and information needed for an effective coaching cycle.

The Five Questions of the Coaching Kata form the basis of the “coaching cycle,” the planned, structured daily interactions between the Kata Coach and the Learner. One Coaching Cycle is going through the Five Questions one time. The primary purpose of daily coaching cycles is to review the Learner’s current work with the Improvement Kata, to discuss how the Learner is working, and to give feedback on potential improvements.

Although progressing toward the established “target condition” is the goal of the work, the primary purpose of Coaching Kata is to develop the Learner’s use of the Improvement Kata so that it becomes a mastered skill, a “second-nature,” natural, useful habit that promotes and supports an ongoing attitude and practice of scientific thinking and acting.

Repeating the same pattern in every cycle builds mastery for the Learner. Similarly, for the Kata Coach, daily work with the Coaching Kata helps build their skills.

To learn and grow in skills mastery, the Learner must go beyond their current comfort zone but also have enough “wins” to affirm their ability to be successful. Kata Coaches can do this by both pushing the Learner to reach for a challenging goal and providing feedback on their IK procedure, not the content of the challenge, to build their IK skills.

The Five Coaching Kata Questions Explained

The Five Questions are vital to beginning Learners and Coaches in developing skills. The questions form a structured routine of scientific thinking and acting. When practiced consistently and regularly, the Kata routine strengthens scientific thinking skills .

Question 1: TARGET CONDITION

What is the target condition for this process? What are we striving to achieve?

At this point in the Coaching Kata, the Coach asks the Learner to state the next Target Condition they are trying to reach, stated as a measurable destination. Ideally, this next target condition will be a step in the direction of the larger challenge.

While it may be tempting to skip over what seems to be a fairly obvious question, don’t! Restating the target frames and anchors the dialogue for the rest of the process. It confirms a shared understanding between the Learner and the Coach and allows the Coach to ask clarifying questions if needed.

Question 2: CURRENT (ACTUAL) CONDITION

What is the current state of the process? Where are we actually at this moment?

This can be measured both in terms of outcome metrics (such as productivity, cost, output, etc.) and process metrics (such as patterns of working and work cycle times).

Establishing Initial Current Condition

At the beginning of the work, the purpose of the current state analysis is simply to establish a baseline, an understanding of the current pattern of work, and outcomes for the focus process. Because the Kata Coach must also understand the focus process, it is helpful to work with the Learner to understand the current condition.

Grasping the initial current condition is a necessary step for establishing a first target condition. Note, this is not the place to identify problems and obstacles, only to establish the starting point of the process that is the focus of the improvement kata.

Process Analysis Kata

- Outcome - Performance: How is the process performing over time? (Graph of RESULTS/process outcomes over time).

- Process - Customer Demand & Planned Cycle Time: What is the rate of demand and the desired rate of “production”?

- Process - Characteristics of the Current Process: Block diagram of work pattern for physical processes or “swim-lane” diagram for office/service processes; measure exit cycles and graph fluctuations; key observations (bullet points about what is happening in the process, not issues, just observations)

- Process - Equipment Capacity (this step is optional): List any equipment restraints observed for processes using automated equipment.

- Process - Labor Needed (if process were stable): How many people are necessary for this process? (Calculate) Identifying the current condition is critical to avoid jumping to conclusions and making assumptions based on lack of understanding of the focus process. Once the current condition is clearly understood, then the target condition can be defined in the same terms.

Ongoing Current Condition Review

After the initial current condition is established at the beginning of the process and reviewed for the first few cycles, subsequent coaching cycles will focus this step on a review of the condition of the process now. It is vital that the current condition includes current data at this point and is stated in relation to the target condition.

Reflect on the Learner’s Last Step

On the back of the Five Questions card is another series of questions to guide the “reflection,” a review of the Learner’s last step to help clarify what was learned and to determine the next step. The four questions correspond to the four columns of the PDCA (Experiment) Record that the Learner keeps as part of the storyboard.

The Learner should have recorded the information on the PDCA Record prior to the coaching cycle. During the review, the Learner points and uses information and data from their PDCA record to respond to the following questions and makes immediate adjustments to the record if needed.

REFLECTION QUESTIONS:

- What was planned as the last step?

- What was expected? (Includes both the experiment and how they proposed to measure it.)

- What actually happened? (Results of experiment, including facts, data, and supporting documents or information.)

- What was learned? (Learner’s interpretation of the results of the experiment.)

Kata Coaches should remember to maintain a posture of open questioning and coaching to help the Learner recognize that prediction errors and disproven hypotheses are not failures, but lessons learned.

Question 3: OBSTACLES

What obstacles are preventing us from reaching the target condition? Which one are you addressing right now?

Learners experiment against obstacles, issues that are thought to be keeping the process from operating at the target condition. The initial list of obstacles is brainstormed in the planning phase. However, the Learner should continue to update the Obstacle Parking Lot prior to a coaching cycle by adding any new obstacles discovered and eliminating those that are no longer relevant.

This is not a list of "action items," but a list of possible impediments to reaching the target condition. Obstacles should be stated as specific and measurable issues related to the target condition. The Learner selects, typically, one Obstacle at a time and runs PDCA cycles/experiments on it until it is overcome (a solution is created). Additional obstacles may be identified in this process and should be added to the Obstacle Parking Lot prior to the next coaching cycle.

Question 4: PLANNING THE NEXT EXPERIMENT

What is your next step? (Start of the next PDCA cycle)

When a Learner reaches their “knowledge threshold,” they no longer have any facts or data and begin guessing. This is the point where the next PDCA cycle (experiment) should begin.

At this point, the Kata Coach should help make sure that the Learner has a well-design experiment ready to go by asking about the following:

- Current threshold of knowledge (what needs to be learned next)

- What the Learner intends to do next and why (based on learning from the previous step)

- What the Learner predicts will result from the upcoming experiment

Either the Coach will accept the Learner’s proposed experiment or will they do more preparation and analysis first and revisit the proposed experiment in the next coaching cycle. As soon as the Coach accept the Learner’s proposed experiment, the Learner should take the next step as quickly as possible while the insights gained from the coaching cycle are fresh in their mind.

Question 5: PREPARING FOR THE NEXT COACHING CYCLE

When we can see the result of this step (establishing due date)?

The final question in the Coaching Kata is the setup for the next coaching cycle. It is designed specifically to ensure a quick turnaround, pushing the Learner to perform the experiment as quickly as possible (ideally the same day) and scheduling the next coaching cycle right away (if not already part of the daily schedule).

Since both the Coach and the Learner are the their “thresholds of knowledge,” nothing further can be accomplished until the Learner completes a PDCA experiment cycle and brings back the results.

Important Notes on Coaching Kata

- Coaches should have practiced extensively with the Improvement Kata themselves prior to working with Learners. One Kata Coach with one Kata Learner is the best. (For new Kata Coaches, being observed by a second, more experienced coach can be beneficial.)

- For maximum effectiveness, perform DAILY coaching cycles (about 20 minutes daily).

- Kata Coaches must lead the Learner through each of the five questions in sequence to ensure mastery of the Improvement Kata skills (no skipping!).

- Focus on the LEARNER not just the results. The goal of Coaching Kata is to develop strong IK/problem-solving skills in the Learner.

- Ask simple, open-ended clarifying questions as needed, but do not “solve” or “explain” for the Learner.

- Remember that the Learner is learning by doing, but will not know what to do at the beginning. Focus on the steps of the Improvement Kata pattern and adjust your coaching as the Learner improves their skills.

- Good Kata Coaches are those who are good listeners, are observant and are invested in their Learners’ success.

- The best Kata Coaches will see the process as an opportunity to develop themselves as well as their Learners.

WHERE TO START

Try starter kata.

Starter Kata are structured routines that you practice deliberately, especially at the beginning, so their pattern becomes a habit and leaves you with new abilities. Your first implementation of Improvement Kata can be your "Starter Kata" routine that will help your team learn fundamental skills. Practicing Starter Kata increases the speed of learning and is particularly helpful when you want to create a shared way of thinking and acting in a group of people, because everyone starts with the same basics. Click below to get our Starter Kata kit , complete with explanation, instructions, and templates to get you going on your Kata journey!

- Leadership Development

- Operational Excellence

- Management Digitalization

- Food and Beverage

- Construction

- Heavy Industry

- Manufacturing

- Manager's Journey

- Cross-Platform Tool

- Digital Gemba Walk

- Collaboration and Rituals

- Coaching and Improvement

- Knowledge Center

- All Features

- Why UTrakk?

- Industry 4.0 and 5.0

Case Studies

- Free Resources

TABLE OF CONTENT

Share this article, download a pdf version., subscribe to our newsletter, toyota kata guide: improvement kata & coaching kata.

Downloaded on: October 1, 2024

• April 24, 2023

dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190584" data-dropdown-placement-param="top" data-term-id="257190584">Lean is a management and organization method that aims to identify and eliminate sources of waste in the work process, allowing the company to increase its performance. In order to make this method a long-term success, the change needs to be made at the human level . Managers and their teams must change the way they think, act and solve problems. That is where the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata comes in, a method that advocates knowledge transmission and repetition over the long term to promote dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190585" data-dropdown-placement-param="top" data-term-id="257190585">continuous improvement .

With the help of our expert Yves LeBrasseur, we invite you to delve into the subject of dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata , to understand how it works, its key elements and its benefits for the company.

Key takeaways

- Understanding the Toyota Kata is crucial for successfully implementing continuous improvement practices in any organization.

- The Toyota Kata provides a structured approach to problem-solving and developing a culture of continuous learning and improvement.

- By following the Toyota Kata, organizations can foster a mindset of experimentation, iteration, and adaptability.

- The Toyota Kata emphasizes the importance of setting clear goals, defining a target condition, and engaging in deliberate practice to achieve desired outcomes.

- Implementing the Toyota Kata requires consistent coaching and leadership support to empower employees and drive sustainable improvement efforts.

In a hurry? Save this article as a PDF.

Tired of scrolling? Download a PDF version for easier offline reading and sharing with coworkers.

Why talk about dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata ?

"One story has often come up in my career: that of a boss who, after hearing about the benefits of Kaizen , the success of Toyota and many other companies that have used this management method, decided to apply it in his own company. To do so, he hires a consultant who comes to do a training with improvement activities and sets up pilot projects with employees. At first, everything went well and everyone was delighted with the new processes. Then the consultant leaves, and unfortunately the initiative slowly disappears. A very classic scenario in the field of Lean Yves LeBrasseur, Senior Expert at Proaction International

What is dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190580" data-dropdown-placement-param="top" data-term-id="257190580">Toyota Kata ?

In dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190586" data-dropdown-placement-param="top" data-term-id="257190586">Japanese dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190595" data-dropdown-placement-param="top" data-term-id="257190595">martial arts , the dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190608" data-dropdown-placement-param="top" data-term-id="257190608">Japanese dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190608" data-dropdown-placement-param="top" data-term-id="257190608"> word "kata" ("form") designates a series of codified and coordinated movements performed as part of a training exercise, which, through repetition, become reflexes, dropdown#toggle" data-dropdown-menu-id-param="menu_term_257190601" data-dropdown-placement-param="top" data-term-id="257190601">second nature . These exercises, when practiced continuously, become perfectly mastered routines and lead to an improvement in technique.