What is Purchasing Cycle? Steps, Purchase Orders Agreements, Blanket Purchase Order

- Post last modified: 10 August 2023

- Reading time: 23 mins read

- Post category: Procurement Management

- What is Purchasing Cycle?

The purchasing cycle refers to the process that a company or individual goes through when making a purchase.

Purchasing is the formal process of buying products and services. The process of purchasing can vary from one organization to another. However, there are some common key steps that are followed by all organizations.

Table of Content

- 1 What is Purchasing Cycle?

- 2.1 Identifying the Need

- 2.2 Specifying the Need

- 2.3 Selecting a Source

- 2.4 Determining the Price

- 2.5 Placing a Purchase Order

- 2.6 Acknowledging the Order

- 2.7 Following up and expediting

- 2.8 Checking the Invoice and Approving the Payment

- 3 Purchase Agreement for Standard Purchase Orders

- 4.1 Framework Contracts

- 4.2 Framework Agreements

- 5.1 Features of Blanket Purchase Order

- 5.2 Release Orders and System-generated Purchase Orders

- 5.3 Open-end Orders

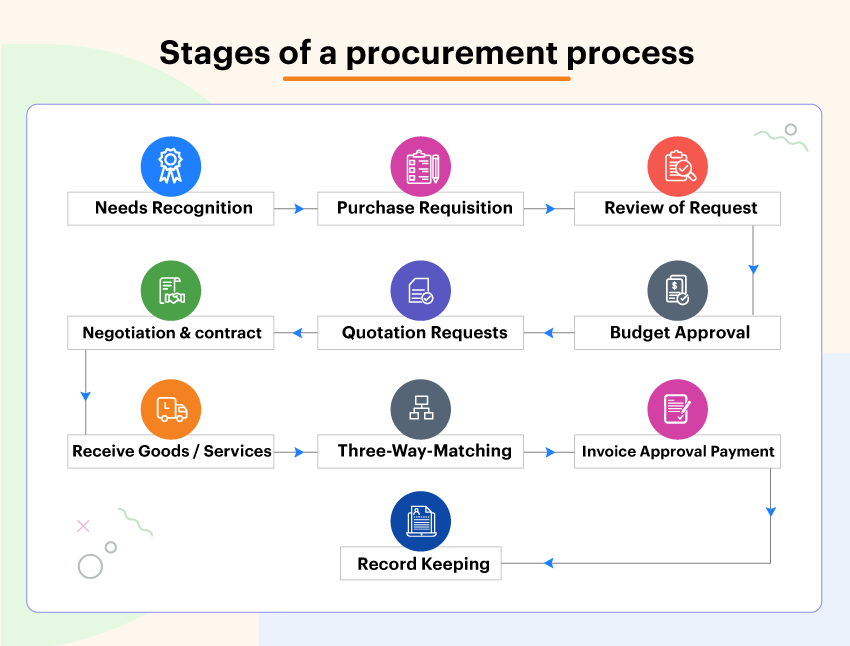

Purchasing Cycle Steps

To make purchasing effective, most organizations follow a purchasing cycle or process. A purchasing cycle is a step-by-step approach to an effective purchasing function.

Let us now discuss the purchasing cycle steps :

Identifying the Need

Specifying the need, selecting a source, determining the price, placing a purchase order, acknowledging the order, following up and expediting, checking the invoice and approving the payment.

It refers to the first step of the purchasing cycle in which the requirements of materials are determined by the user department. These requirements are determined by taking into consideration the purchase requisitions and BOMs, which were discussed in the previous chapter.

It involves determining the exact quantity of materials to be purchased for production. Different departments of an organization need to define their requirements in the purchase requisition form. The approved PR reaches the purchasing department for making the purchase.

If there is any error or unclear description in a requisition form, the purchasing department does not make any changes to it, rather the department sends the form back to the respective department for clarification.

It refers to one of the most important steps of the purchasing cycle. The quality of materials depends on the source from where they are procured. Therefore, the purchasing department is responsible for selecting the right source for procuring materials.

To do so, the department maintains a list of reputed suppliers. The purchase department also selects a supplier by inviting tenders through advertisements.

As discussed earlier, the purchasing department is responsible for procuring the optimum-quality materials at the lowest price. Therefore, it is important for the purchasing department to analyze its budget, perform market research and determine the best price for procuring materials.

The purchase department generally uses three ways for determining the best price of materials, which are:

- Vendor catalog : It is a list of different materials along with their prices and quantity, available from different vendors. The department only needs to check the current list to determine the best price of materials.

- Negotiation : It involves bargaining with the supplier to reach the best price for materials.

- Tendering : It refers to a method mostly used by government organizations in which the buyer sets a price for materials and the supplier needs to bid for receiving the purchase order from the buyer.

A purchase order is a legal contract that specifies the entire agreement between the purchasing department and the supplier. It defines the agreed price, terms and conditions, and specifications of materials to be purchased. The purchase order helps in preventing any misunderstanding between the two parties.

After the order placement, it has to be acknowledged by the supplier. Acknowledgement is all about getting confirmation from the supplier about the timely delivery of materials. Without acknowledgement, the order will remain only “an offer to purchase” with no legal standing.

Once the supplier issues acknowledgement, it becomes a purchase contract and the same needs to be noted in the purchasing system.

It ensures that the items are delivered by the supplier on time. No special expediting procedure is required in the following conditions:

- Good production planning

- Less engineering alterations

- Efficient inventory control

- Proper purchase order

- Appropriate supplier

This is the last step of the purchasing cycle wherein the invoice is verified by matching it with the purchase order and GRN. This is called three-way matching. If there is no mismatch between the materials ordered and received, payment is made to the supplier.

In certain cases, the invoice needs to be matched only with the purchase order. This is called 2-way matching, and it is applicable in cases where GRN is not raised. For example, in the case of blanket purchase orders, GRN is not raised.

As discussed, the purchasing cycle is applicable to any standard purchase order. However, all purchases do not go through such elaborated stages. Owing to the nature of repetitive purchases of the same materials, organizations have invented new methods that simplify the purchasing cycle and integrate it with the inventory management process.

In this chapter, you will study some important purchasing methods in detail.

Purchase Agreement for Standard Purchase Orders

The Chartered Institute of Procurement and Supply (CIPS) defines a purchase order (PO) as a document issued by a buyer to his/her supplier that defines what is needed, in what quantity, when performance is required, and on what terms, including price and payment terms.

The issue of a purchase order is a prerequisite in many payment systems for the payment of invoices. A sample format of the purchase order was shown in the previous chapter.

It is important to understand that manufacturing organizations producing the same set of finished products require similar sets of materials and components for each and every production schedule.

Given that the manufacturing plant and the nature of production methods do not change, the required raw materials and component parts for manufacturing any particular finished product would not vary with every production plan. Only the quantity of raw materials and components may change depending on the customer demand forecasts and production plans.

Similarly, procurement of standard inventory items that are required on a day-to-day basis usually involves the same set of suppliers who have already been approved (through a supplier selection process) by the organization for sourcing its inventory requirements from them.

Therefore, organizations are not required to identify a new supplier every time an inventory procurement requirement is raised, owing to the repetitive nature of the requirement.

To fulfill their standard, repetitive purchase requirements, organizations enter into long-term purchase agreements with suppliers. These purchase agreements envisage a long-term partnership with suppliers in terms of procurement commitment from the buyer organization.

Different types of organizations like manufacturing, service, software, etc. use different types of purchase agreements depending on the nature of their procurement needs.

Types of Purchase Agreements

CIPS classifies purchase agreements into the following two categories:

Framework Contracts

Framework agreements.

Framework contracts are legal contracts where the buyer commits upfront that it will purchase a specified quantity of items in a given period. For example, a manufacturing organization may enter into a framework contract with an electric utility for the off-take of a specified amount of electricity during a given period.

Similarly, a pharmaceutical company might forecast that it requires a particular amount of chemicals to be used as raw materials in its batch production processes at any given period. Though the company might be certain of its requirements, it may not need to purchase the entire quantity at once.

Instead, it can enter into a contract wherein it commits to purchase the entire quantity from the same supplier over a specified period. This helps fix both the price and the supplier at the best possible terms for the entire production period. Such a contract is called a framework contract.

A framework agreement is not a legal contract but only an agreement to buy an unspecified quantity over a particular period of time.

For example, an automobile major like General Motors knows that it would require sourcing anti-braking systems from a supplier like Robert Bosch, over a period of time. But General Motors does not want to enter into a framework contract that specifies that it will purchase a specific quantity from Robert Bosch during a particular period.

In that case, it can enter into a framework agreement with Robert Bosch wherein it only commits (or firms up its intention) to purchase anti-braking systems over a period at given terms and conditions including the price.

So, a framework agreement need not specify any quantity nor carry a legal commitment to purchase a fixed quantity. It may not even specify delivery dates or the shipment location. Most manufacturing organizations enter into framework agreements due to their flexible nature.

Standard purchase orders are similar to framework agreements as they do not have a legal contract but only an offer to purchase. A purchase order becomes a contract only after the supplier accepts it by acknowledging the same and committing to supply products/services as per the terms mentioned in the purchase order.

Blanket Purchase Order

The term ‘blanket purchase order’ is used differently in the context of different organizations and ERP modules. The APICS (Association for Purchasing and Inventory Control Specialists) dictionary defines a blanket purchase order as a long-term commitment to a supplier for material against which short-term releases will be generated to satisfy requirements.

The CIPS definition says blanket purchase orders are purchase orders placed on suppliers that cover a range of products or a time period that commits to a volume of one product.

In CIPS terminology, a blanket purchase order is a form of framework agreement. CIPS defines a blanket purchase order as an agreement between buyer and seller whereby certain goods will be purchased at prices established or agreed to by way of a formula over a period of time.

In other words, it is an agreement with the supplier where the buyer commits to purchase the items over a specified period. It may or may not specify an indicative quantity.

A blanket purchase order is generally meant for a particular item or a group of items required to be ordered repetitively from a single supplier. It is basically an open order effective for a specified period, say, for one year. It eliminates the need for issuing a separate purchase order whenever there is a need for materials.

The buyer will enter into a blanket purchase order through due negotiations after which ordering of any item covered by the blanket purchase order only requires a release order. Through this mechanism, the order and receipt of materials as per the production schedule become a routine matter between the buyer and the supplier.

Most purchases in the organization covering routine standard items happen only through blanket purchase orders. Standard purchase orders are used only for one-off purchases from new suppliers.

When a blanket purchase order for an item is negotiated, the buyer and the supplier evaluate the anticipated demand for the item over a period of time. The two parties then agree to the terms and conditions including price, quantity, discounts, specifications, quality, and delivery lead times.

For a purchase to be made by the blanket purchase order, individual purchase orders and GRNs are not raised. The blanket purchase order reduces transaction processing costs which can have a significant positive impact on the total acquisition costs of materials.

Features of Blanket Purchase Order

Release orders and system-generated purchase orders, open-end orders.

The salient features of a blanket purchase order are summarised below:

- A blanket purchase order is a type of long-term purchase order and is the most preferred and widely adopted method for all repetitive and standard purchases.

- A blanket purchase order covers a procurement commitment to a supplier for specific products at an agreed-upon price for a specified period.

- A blanket purchase order eliminates the need of issuing a purchase order every time there is a requirement for the material.

- To manage routine and standard inventory items, buyers enter into blanket agreements that enable the shipment of items through release orders obviating the need to go through an elaborate purchasing cycle.

- A blanket purchase order is based on negotiated terms and conditions including price, quantity, discounts, and projected demand over a period. It leaves the delivery date and the ship-to location open.

- Release orders are issued against blanket purchase orders as and when material requirements are identified in the MRP system.

- On shipment, the supplier raises the invoice for payment.

- No GRN is raised for shipments based on blanket purchase orders

- Two-way matching is done while making payment for shipments on the basis of blanket purchase orders.

- Total invoices raised against a blanket purchase order cannot go beyond the limit set for blanket purchase orders.

Release orders (also called material purchase releases) are authorizations issued to suppliers to make shipments as and when required as per the blanket purchase order agreement.

A copy of material purchase releases is also sent to purchasing, accounts payables, and store departments. Release orders specify the current quantity to be shipped, delivery date, and ship-to location. These orders are based on material requirements identified by the MRP system. These orders raised by the MRP system are based on the BOM associated with the finished product.

For example, for a desktop PC, there is a demand for 1,000 finished products, that is 1,000 PCs. To cater to this demand, release orders derived from BOM, for components or parts to be replenished will require the shipment of 1,000 monitors, 1000 keyboards, 1000 mouses, 1,000 hard disks, etc (assuming these are externally sourced from suppliers).

In an ERP system, automatic release orders for each of these components will be directly issued to the suppliers as per the respective blanket purchase order details. Such release orders are called system-generated purchase orders/release orders. In the real world, most purchases happen only through such automatic system-generated release orders.

In such release orders, in the first few weeks (or days depending on lead time), the material requirement indicated will be the actual shipments required as per the delivery date specified, while the requirement stated for the subsequent period will be the quantity forecast for the period.

It is also practiced by many supply chain-driven manufacturing organizations to share material requirement forecasts with their suppliers. This would help the supplier plan supply requirements in advance.

Open-end orders are similar to blanket purchase orders. However, they allow for the inclusion/deletion of additional items over a period of time. Such orders are useful for procuring MRO and production support items discussed in the previous chapter.

Usually, these items are of low cost, high volume, and large in number. The required items can also change and can be unpredictable. Open-end orders allow the convenience of modifying standard blanket purchase orders. The period of the order could be up to one year or till renewal.

- Baily, P., Farmer, D., Crocker, B., Jessop, D., & Jones, D. (2008). Procurement principles and management. Pearson Education.

- Monczka, R. M., Handfield, R. B., Giunipero, L. C., & Patterson, J. L. (2015). Purchasing and supply chain management. Cengage Learning.

- Bower, D. (2010). Management of procurement (1st ed.). London: Thomas Telford.

- Blanket Orders | (2017). Materialsmanagement.info. Retrieved 1 March 2023, from https://www.materialsmanagement.info/procurement-management/blanket-orders.htm

- APICS – The Premier Association for Supply Chain Management. Apics.org. Retrieved 1 March 2023, from http://www.apics.org

- Blanket Order: Procurement and Payment Services – Northwestern University. Northwestern.edu. Retrieved 1 March 2023, from http://www.northwestern.edu/procurement/about/procurement-methods/blanket-order.html

- Supply Chain Management Publications | American Purchasing Society. American-purchasing.com. Retrieved 1 March 2023, from https://www.american-purchasing.com/propurch

Business Ethics

( Click on Topic to Read )

- What is Ethics?

- What is Business Ethics?

- Values, Norms, Beliefs and Standards in Business Ethics

- Indian Ethos in Management

- Ethical Issues in Marketing

- Ethical Issues in HRM

- Ethical Issues in IT

- Ethical Issues in Production and Operations Management

- Ethical Issues in Finance and Accounting

- What is Corporate Governance?

- What is Ownership Concentration?

- What is Ownership Composition?

- Types of Companies in India

- Internal Corporate Governance

- External Corporate Governance

- Corporate Governance in India

- What is Enterprise Risk Management (ERM)?

- What is Assessment of Risk?

- What is Risk Register?

- Risk Management Committee

Corporate social responsibility (CSR)

- Theories of CSR

- Arguments Against CSR

- Business Case for CSR

- Importance of CSR in India

- Drivers of Corporate Social Responsibility

- Developing a CSR Strategy

- Implement CSR Commitments

- CSR Marketplace

- CSR at Workplace

- Environmental CSR

- CSR with Communities and in Supply Chain

- Community Interventions

- CSR Monitoring

- CSR Reporting

- Voluntary Codes in CSR

- What is Corporate Ethics?

Lean Six Sigma

- What is Six Sigma?

- What is Lean Six Sigma?

- Value and Waste in Lean Six Sigma

- Six Sigma Team

- MAIC Six Sigma

- Six Sigma in Supply Chains

- What is Binomial, Poisson, Normal Distribution?

- What is Sigma Level?

- What is DMAIC in Six Sigma?

- What is DMADV in Six Sigma?

- Six Sigma Project Charter

- Project Decomposition in Six Sigma

- Critical to Quality (CTQ) Six Sigma

- Process Mapping Six Sigma

- Flowchart and SIPOC

- Gage Repeatability and Reproducibility

- Statistical Diagram

- Lean Techniques for Optimisation Flow

- Failure Modes and Effects Analysis (FMEA)

- What is Process Audits?

- Six Sigma Implementation at Ford

- IBM Uses Six Sigma to Drive Behaviour Change

- Research Methodology

- What is Research?

- What is Hypothesis?

- Sampling Method

- Research Methods

- Data Collection in Research

- Methods of Collecting Data

- Application of Business Research

- Levels of Measurement

- What is Sampling?

- Hypothesis Testing

- Research Report

- What is Management?

- Planning in Management

- Decision Making in Management

- What is Controlling?

- What is Coordination?

- What is Staffing?

- Organization Structure

- What is Departmentation?

- Span of Control

- What is Authority?

- Centralization vs Decentralization

- Organizing in Management

- Schools of Management Thought

- Classical Management Approach

- Is Management an Art or Science?

- Who is a Manager?

Operations Research

- What is Operations Research?

- Operation Research Models

- Linear Programming

- Linear Programming Graphic Solution

- Linear Programming Simplex Method

- Linear Programming Artificial Variable Technique

- Duality in Linear Programming

- Transportation Problem Initial Basic Feasible Solution

- Transportation Problem Finding Optimal Solution

- Project Network Analysis with Critical Path Method

- Project Network Analysis Methods

- Project Evaluation and Review Technique (PERT)

- Simulation in Operation Research

- Replacement Models in Operation Research

Operation Management

- What is Strategy?

- What is Operations Strategy?

- Operations Competitive Dimensions

- Operations Strategy Formulation Process

- What is Strategic Fit?

- Strategic Design Process

- Focused Operations Strategy

- Corporate Level Strategy

- Expansion Strategies

- Stability Strategies

- Retrenchment Strategies

- Competitive Advantage

- Strategic Choice and Strategic Alternatives

- What is Production Process?

- What is Process Technology?

- What is Process Improvement?

- Strategic Capacity Management

- Production and Logistics Strategy

- Taxonomy of Supply Chain Strategies

- Factors Considered in Supply Chain Planning

- Operational and Strategic Issues in Global Logistics

- Logistics Outsourcing Strategy

- What is Supply Chain Mapping?

- Supply Chain Process Restructuring

- Points of Differentiation

- Re-engineering Improvement in SCM

- What is Supply Chain Drivers?

- Supply Chain Operations Reference (SCOR) Model

- Customer Service and Cost Trade Off

- Internal and External Performance Measures

- Linking Supply Chain and Business Performance

- Netflix’s Niche Focused Strategy

- Disney and Pixar Merger

- Process Planning at Mcdonald’s

Service Operations Management

- What is Service?

- What is Service Operations Management?

- What is Service Design?

- Service Design Process

- Service Delivery

- What is Service Quality?

- Gap Model of Service Quality

- Juran Trilogy

- Service Performance Measurement

- Service Decoupling

- IT Service Operation

- Service Operations Management in Different Sector

Procurement Management

- What is Procurement Management?

- Procurement Negotiation

- Types of Requisition

- RFX in Procurement

- Vendor Managed Inventory

Internal Conflict During Purchasing Operation

- Spend Analysis in Procurement

- Sourcing in Procurement

Supplier Evaluation and Selection in Procurement

- Blacklisting of Suppliers in Procurement

Total Cost of Ownership in Procurement

- Incoterms in Procurement

- Documents Used in International Procurement

- Transportation and Logistics Strategy

- What is Capital Equipment?

- Procurement Process of Capital Equipment

Acquisition of Technology in Procurement

- What is E-Procurement?

E-marketplace and Online Catalogues

- Fixed Price and Cost Reimbursement Contracts

- Contract Cancellation in Procurement

- Ethics in Procurement

- Legal Aspects of Procurement

Global Sourcing in Procurement

Intermediaries and countertrade in procurement.

Strategic Management

- What is Strategic Management?

- What is Value Chain Analysis?

- Mission Statement

- Business Level Strategy

- What is SWOT Analysis?

- What is Competitive Advantage?

- What is Vision?

- What is Ansoff Matrix?

- Prahalad and Gary Hammel

- Strategic Management In Global Environment

- Competitor Analysis Framework

- Competitive Rivalry Analysis

- Competitive Dynamics

- What is Competitive Rivalry?

- Five Competitive Forces That Shape Strategy

- What is PESTLE Analysis?

- Fragmentation and Consolidation Of Industries

- What is Technology Life Cycle?

- What is Diversification Strategy?

- What is Corporate Restructuring Strategy?

- Resources and Capabilities of Organization

- Role of Leaders In Functional-Level Strategic Management

- Functional Structure In Functional Level Strategy Formulation

- Information And Control System

- What is Strategy Gap Analysis?

- Issues In Strategy Implementation

- Matrix Organizational Structure

- What is Strategic Management Process?

Supply Chain

- What is Supply Chain Management?

- Supply Chain Planning and Measuring Strategy Performance

- What is Warehousing?

- What is Packaging?

- What is Inventory Management?

- What is Material Handling?

- What is Order Picking?

- Receiving and Dispatch, Processes

- What is Warehouse Design?

- What is Warehousing Costs?

You Might Also Like

What is inco terms classification, 11 icc incoterms, what is vendor managed inventory (vmi) features, benefits, what is rfx in procurement, what is procurement negotiation phases, steps in development strategy, outcomes, methods for win-win, what is capital equipment challenge, leasing equipment in procurement, leave a reply cancel reply.

You must be logged in to post a comment.

World's Best Online Courses at One Place

We’ve spent the time in finding, so you can spend your time in learning

Digital Marketing

Personal growth.

Development

What's Planergy?

Modern Spend Management and Accounts Payable software.

Helping organizations spend smarter and more efficiently by automating purchasing and invoice processing.

We saved more than $1 million on our spend in the first year and just recently identified an opportunity to save about $10,000 every month on recurring expenses with Planergy.

Cristian Maradiaga

Download a free copy of "indirect spend guide", to learn:.

- Where the best opportunities for savings are in indirect spend.

- How to gain visibility and control of your indirect spend.

- How to report and analyze indirect spend to identify savings opportunities.

- How strategic sourcing, cost management, and cost avoidance strategies can be applied to indirect spend.

The Purchasing Cycle Explained

- Written by Lyle Del Vecchio

- 11 min read

How much your company spends to do business, and how often, plays an important role in your overall success. Transforming cash into goods and services, the purchasing cycle is at the core of procurement and can have a major impact on your productivity, competitiveness, and profitability.

Understanding your company’s purchasing cycle is the first step toward optimizing it. With the help of technology and process improvements, you can ensure your purchasing department is building value for your company while reducing costs due to wasted time, energy, and resources.

What is the Purchasing Cycle?

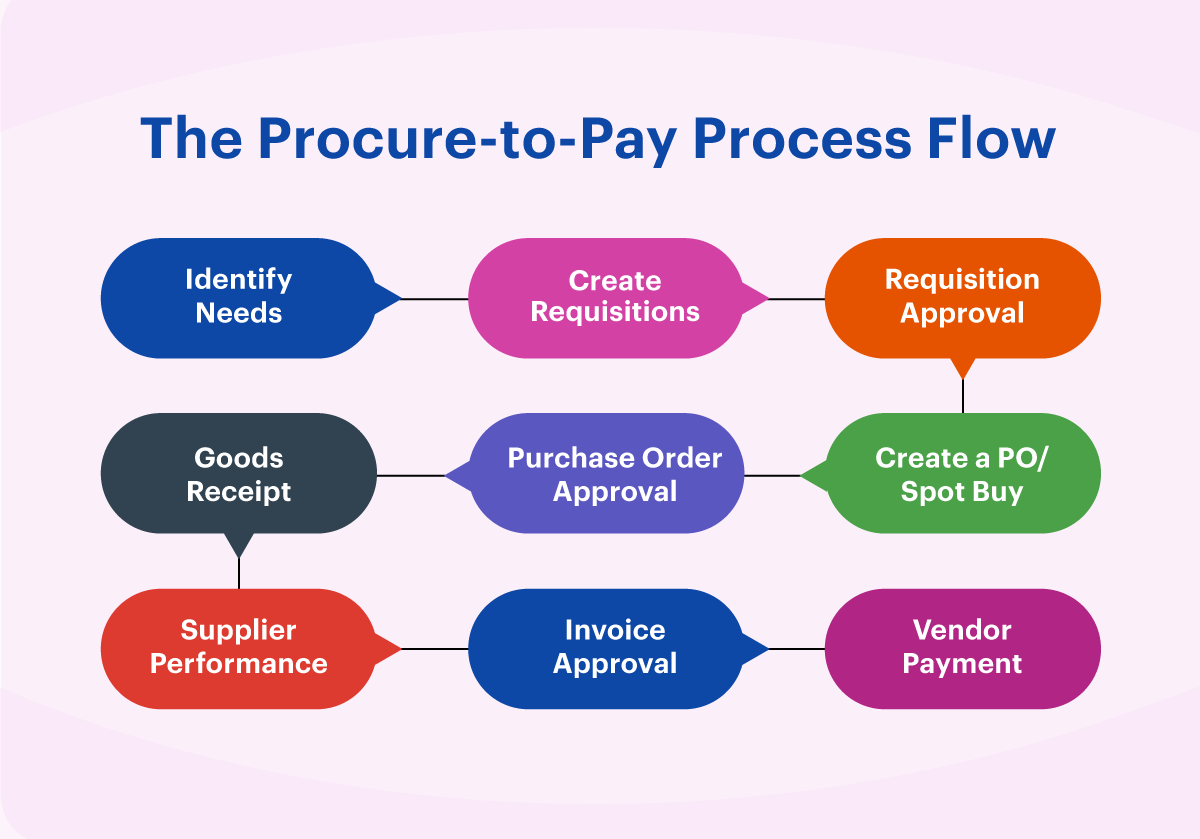

The purchasing cycle—also called the procurement cycle or procure-to-pay (P2P)—is the process by which you order, obtain, and pay for the goods and services your business needs.

For companies of all sizes, from local small businesses to global megacorps, the purchasing cycle begins with needs analysis and ends with payment and record keeping. In between, they may generate a purchase order, pay for goods directly, or invite tenders (also known as bids) to encourage more aggressive and price-effective competition between suppliers wishing to fulfill a specific need.

The Purchasing Cycle, Step By Step

For companies of all sizes, from local small businesses to global megacorps, the purchasing cycle begins with needs analysis and ends with payment and record keeping.

In between, they may generate a purchase order , pay for goods directly, or invite tenders (also known as bids ) to encourage more aggressive and price-effective competition between suppliers wishing to fulfill a specific need.

Most companies have a quirk or two, but in general the process follows a fairly straightforward series of events:

Needs Analysis

This stage of the purchase cycle is dedicated to identifying the need to be met, whether it’s a reorder, raw materials for a new product produced by the company, or office supplies.

Needs Clarification

Once the need’s been identified, the variety (e.g., brand), amount required, and delivery schedule need to be established.

Purchase Requisition and/or Purchase Order

With the details settled, the requesting party has a couple of options. Generally, those without the authority to approve direct purchase orders will first create and submit a purchase requisition , which is an internal document requesting that approved parties obtain goods and services. Upon approval, the purchase requisition is used to create a purchase order , which is the actual order sent to the supplier for the goods and services required.

Authorization

The purchase order (generated from a purchase requisition or not) must also be approved. The purchase order process benefits from automation and artificial intelligence (AI), usually through the use of purchase order software that’s part of a comprehensive procurement software package.

Not only does automation permit role assignments and automatic routing and tracking of all purchase orders and approvals/rejections/revisions, but it allows for real-time adjustments and transparent communication between all parties involved. In addition, automatic reminders can be created to ensure no PR or PO is left to languish.

Supplier Review

If you’ve already integrated an automated procurement solution into your workflow, chances are the list of approved and available suppliers will obviate this step in the process—especially for repeat orders. But if you’re adding new products, or new suppliers for existing products to the system, then each candidate must be reviewed for compliance, performance, and reliability.

Supplier Selection

At this stage, the purchaser chooses the supplier who’ll be filling the order, either from the pre-vetted list in their software catalog or through other means.

Price and Term Negotiations

This step is also made infinitely easier if your workflow is built around procurement software automation. Centralized contract and document management and information sharing means previously-negotiated contract terms and best price are already available for each vendor on the approved list. New vendors being added to the system will have this information added as your legal team completes and certifies your company’s agreement(s) with the vendor.

If your company doesn’t use automation, then your team will need to sit down with the vendor to negotiate payment terms and conditions.

Order Placement

At this point, the buyer officially places the order and creates a binding purchase agreement between your business and the vendor.

Receiving and Inspection

For material goods, arriving shipments are inspected for completeness and integrity, with any shortages and broken goods marked to be credited back to the buyer. The invoice is either included with the goods or sent separately by the vendor.

Inventory management is either manually updated or handled automatically by the procurement software, which links the shipping documentation to the original purchase order, invoice, related correspondence, and other documents for data analysis and auditing purposes.

The invoice is reviewed for accuracy against the purchase order, invoice, and other documentation. Depending on the terms established for the supplier and the approval of the reviewing party, payment is issued (usually within 30, 60, or 90 days).

Records Management

Businesses still using manual systems follow up by updating their inventory totals and purchasing ledger. Purchasing software automates this step, as documents are cross-connected and update automatically across all departments.

What About Tenders?

The purchasing process when using tenders is very similar to the standard purchasing cycle , with a few important changes:

- Needs Analysis is much more narrowly defined at inception, and often supported by a business case.

- The Approval Process requires more review and may be granted by departmental or even C-level management.

- The Tender Process is used instead of the PR/PO model, and involves:

- A very specific Request for Proposal (RFP), written to formally outline the goods and services needed and request approval.

- Tender invitations, which are posts made to the public (either online or in print) inviting vendors to bid for the right to fulfill the request.

- Pre-Qualification Questionnaires (PQQs) are sent to each of the most promising candidates to provide greater detail about their capacity, history, and operations.

- Tenders (i.e., bids) arrive from the pre-qualified candidates within the specified period.

- Each bid is reviewed, and the candidates interviewed to further qualify them for consideration.

- All valid tenders are carefully reviewed over the course of days or even weeks. The winning bidder is granted the contract, based on their credentials.

- Negotiation brings the winning supplier and the buyer together to hammer out the terms and conditions (in general, price is already locked in during the tender process). The legal contract is formally awarded to the bidder when negotiations conclude.

- Contract Management is handled by the company’s procurement, financial, and legal staff. During the management period, goods are received and reviewed, and fulfillment of the required terms and conditions verified.

- Review, Approval, and Payment all rely on complete, accurate, and on-time fulfillment of the contract. Any exceptions are noted and the buyer is compensated according to the terms negotiated. Once the contract terms are confirmed, payment is made and the relationship either ends, or the supplier is added to the company’s vendor management system as a pre-approved candidate for future tenders.

- Records Management is identical to the standard procurement cycle.

Take Control of Your Purchasing Cycle

Having mastered the purchase cycle, you’re ready to squeeze maximum value from it.

Combined with machine-learning-enabled software and automation, formalizing your purchasing cycle lets you fine-tune all the stages of the procurement process to reduce your workload, eliminate delays and errors, and simplify everything from inventory to materials management to financial forecasting.

What’s your goal today?

1. use planergy to manage purchasing and accounts payable.

- Read our case studies, client success stories, and testimonials.

- Visit our “Solutions” page to see the areas of your business we can help improve to see if we’re a good fit for each other.

- Learn about us, and our long history of helping companies just like yours.

2. Download our guide “Indirect Spend Guide”

3. learn best practices for purchasing, finance, and more.

Browse hundreds of articles , containing an amazing number of useful tools, techniques, and best practices. Many readers tell us they would have paid consultants for the advice in these articles.

Related Posts

- Spend Management

Catalog Management in Procurement: What Is It, Types of Catalogs, Challenges and Best Practices To Manage Them

- 17 min read

Discretionary Expenses: What Are They, Examples, and How To Control Them In Business

- 18 min read

Procurement Methods: How To Source and Evaluate The Best Suppliers To Work With

- 16 min read

PROCUREMENT

- Purchasing Software

- Purchase Order Software

- Procurement Solutions

- Procure-to-Pay Software

- E-Procurement Software

- PO System For Small Business

- Spend Analysis Software

- Vendor Management Software

- Inventory Management Software

AP & FINANCE

- Accounts Payable Software

- AP Automation Software

- Compliance Management Software

- Business Budgeting Software

- Workflow Automation Software

- Integrations

- Reseller Partner Program

Business is Our Business

Stay up-to-date with news sent straight to your inbox

Sign up with your email to receive updates from our blog

This website uses cookies

We use cookies to personalise content and ads, to provide social media features and to analyse our traffic. We also share information about your use of our site with our social media, advertising and analytics partners who may combine it with other information that you’ve provided to them or that they’ve collected from your use of their services.

Read our privacy statement here .

- E-learning for Teams

- Advertisers/Sponsors

- Certifications

- Training Catalog

- Advanced Negotiations

- Expert Strategic Sourcing

- Cost Price Analysis

- World Class Procurement

- Technology Contracting

- Training for Managers

- Training for Teams

- More Trainings ...

- Testimonials

- Videos on Demand

- E-Reports/Templates/Checklists

- Strategic Sourcing

- Category Management

- Purchasing Management

- Procurement Strategies

- Procurement Negotiations

- Cost Management

- Contract Management

- Legal Contract Terms

- Vendor Management

- RFX/Tender Management

- Global Sourcing

- Materials Management

- Inventory Control management

- Mission, Vision, Values

- Write for Us

- Train/Speak for Us

- Media Partners

Steps To Purchasing Cycle - Standard & Tender Process

So what exactly is a purchasing cycle? Well it’s the steps taken to order and pay for products that a business requires. The purchasing cycle determines the frequency that products are purchased.

Below you will find the steps for a Standard procurement cycle, and then when it involves tendering.

I. 11 Steps in a Standard Procurement Cycle

- The Need You need to identify that there is a need to update the inventory or stock. You may also need a business service or ad hoc product.

- Specify Now you need to decide how much and when you want the products or services delivered.

- Requisition or Order This is when you write the purchase order or requisition order.

- Financial Authority Before the order can be placed, it usually requires some kind of authority for its purchase. With some purchase orders, this is reasonably automatic. With a large order that will be put out to tender it could be multi staged.

- Research Suppliers Repetitive orders usually have set suppliers, although it does no harm to review the options sometimes. Other orders will either need to go out to tender or there will be a choice of suppliers.

- Choose Supplier The supplier is now chosen.

- Establish Price and Terms In a large company, many suppliers will be contracted with a Master Agreement where prices and terms are set for a defined period. For other orders, now is the time to negotiate terms and prices.

- Place Order At this stage in the purchasing cycle, the order is placed and this becomes a contract between the business and the supplier.

- Order Received and Inspected The goods are delivered, checked in the warehouse and entered into the inventory . Shortages and breakages are reported to the supplier for the appropriate credits to be supplied.

- Approval And Payment Usually within 30 days, the invoices are received and paid.

- Update Of Records The purchasing ledger and stock records are updated. This is automatically done by many purchasing computer systems.

II. 14 Steps for Purchasing Cycle with Tenders

- The Need In this case, the need usually goes through a business case and is then tightly defined and specified.

- Financial Authority This usually happens at a higher level and includes the management of the department that requires the goods.

- RFP A Request For Proposal (RFP) is written, in which the need is highly specified.

- Invite Tenders This is always done formally, usually by posting the request in trade magazines and appropriate web sites. Government projects are posted on government web sites.

- PQQ A Pre Qualification Questionnaire (PQQ) is sent out to likely suppliers in order to select a short list of appropriate potential suppliers.

- Tenders The tenders are sent in from the qualified suppliers.

- Qualifying A number of meetings are held to clarify any questions that suppliers may have.

- Evaluation This is the most exciting part of the purchasing cycle and can take many weeks for a big tender. All the tenders are evaluated and the requirement awarded to the winning bidder.

- Negotiation The fine print of the terms and conditions are negotiated with the chosen supplier. The price is fixed at the bid price.

- Contract Award In a very short time, the contract is awarded to the chosen bidder.

- Manage Contract This is the period in the purchasing cycle when the goods are delivered.

- Approval And Payment If the contract is carried out completely then full payment is made. If there are problems, there may be a damage request.

- Sign Off At the end of the contract work and deliveries, the contract is signed off and all relationships with the supplier are finished.

Return from Purchasing cycle to Purchasing Strategies

Return from Purchasing cycle to Purchasing Procurement Center Homepage

Company & Services

Procurement Trainings

Procurement Certification

In-House Training for Teams

Online Training/E-learning for Teams

Online Trainings for Individuals About Mission, Vision, Values Contact

Advertisers/Sponsors Media Partners Write for Us Train/Speak for Us

Procurement Topics & Resources

Understanding The Purchase Cycle

Navigating the Purchase Cycle: Understand Customer Behavior and Boost Sales with Our Expert Insights.

The purchase cycle refers to the steps involved in processing a purchase order , from its initial creation to the final payment. This cycle encompasses the entire procurement process, also known as the procure-to-pay cycle.

The purchase cycle typically starts with identifying an organization's need for goods or services. This need is translated into a purchase requisition, which is then reviewed by the procurement team. They evaluate potential suppliers, considering quality, cost, delivery times, and supplier performance.

Once the procurement team selects a supplier, a purchase order is created. This document outlines the purchase details, including quantities, pricing, and delivery terms. The purchase order is then sent to the supplier, who acknowledges and accepts it.

After the supplier delivers the goods or services, the organization verifies the delivery and checks for discrepancies. If everything is in order, the purchase order moves to the next step, where the supplier's invoice matches the purchase order and payment terms.

The final step in the purchase cycle is the payment to the supplier. Key performance indicators (KPIs) are essential in measuring the purchase cycle's efficiency and effectiveness.

These KPIs may include procurement cycle time, supplier performance, purchase order accuracy, and cost savings achieved through the procurement process. By monitoring these indicators , organizations can identify areas for improvement and ensure a smooth and efficient purchase cycle.

Many organizations utilize a purchase order system to streamline and automate the purchase cycle . This software helps manage the entire process, from creating purchase orders to tracking deliveries and payments, improving efficiency, and reducing manual errors.

Overall, the purchase cycle is critical to the procurement process, ensuring organizations can efficiently and effectively obtain the goods and services they need.

The Stages Of The Purchase Cycle

The purchasing cycle consists of several stages organizations go through when procuring goods or services. It starts with the intent stage, where customer needs are identified. This stage involves understanding the organization's requirements and evaluating potential solutions to fulfill those needs.

Once the customer needs have been identified, the next stage is assessing the financial implications . This stage involves analyzing the cost and budget considerations associated with the purchase.

It is important to evaluate the financial impact of the procurement decision and ensure that it aligns with the organization's financial goals. Afterwards, seeking approval from key stakeholders is crucial.

This stage involves presenting the identified customer needs, potential solutions, and financial implications to decision-makers within the organization. Approval is sought to move forward with the procurement process.

Once approval is obtained, the next stage is drafting a request for proposal (RFP). The RFP outlines the organization's requirements and invites potential suppliers to submit proposals. It provides suppliers detailed information about the organization's needs and expectations, allowing them to prepare comprehensive proposals.

The final stage in the purchase cycle is supplier selection and negotiation . This involves evaluating the proposals received and selecting the most suitable supplier based on quality, cost, delivery times, and supplier performance. Negotiations may then take place to finalize the terms and conditions of the purchase agreement.

The Intent Stage

The intent stage is the initial phase of the purchasing cycle, where a customer recognizes a need or desire for a particular product or service. It is when a potential buyer becomes aware of their requirement and begins researching and exploring options.

During this stage, customers may conduct online searches , read reviews, seek recommendations, and gather information to evaluate different products or services available.

The intent stage plays a crucial role in shaping the customer's journey as it sets the foundation for the subsequent stages of the purchase cycle. By understanding the intent stage, businesses can tailor their marketing efforts to capture the attention of potential customers and guide them toward making informed purchasing decisions.

Identifying Customer Needs

In the purchase cycle, identifying the target audience's needs is a crucial step that sets the foundation for a successful purchase process. The need identification stage begins when someone submits a request to the purchasing department, communicating a need that can vary in complexity.

One key step in identifying customer needs is the submission of requests in writing. This ensures that the request is properly documented and can be tracked throughout the purchasing process.

It is important for these requests to be sufficiently detailed, providing clear information about the desired product or service, quantity, quality standards, and any other specifications.

By submitting a detailed request in writing, potential suppliers and the purchasing department can accurately assess the customer's needs and evaluate their options. This helps streamline the purchasing process, reducing the risk of misunderstandings or confusion.

Identifying customer needs in the purchase cycle begins with submitting a detailed request to the purchasing department. By providing clear and comprehensive information, customers facilitate the procurement team's ability to identify the most suitable solutions, ensuring that the subsequent stages of the purchase cycle can be executed smoothly and efficiently.

Exploring Potential Solutions

Customers can explore potential solutions to address their needs during the purchase cycle. This allows them to thoroughly evaluate different options before making a final purchase decision.

One option customers can consider is exploring different products available in the market. They can compare features , specifications, and pricing to find the best match for their requirements.

Customers can explore services offered by various providers, such as installation, maintenance, or customer support, which can significantly enhance their overall experience.

In addition to traditional products and services, customers can explore alternative methods to meet their needs. For example, they can explore renting or leasing a product instead of making a full purchase, which can be more cost-effective in certain situations.

They can also explore the option of seeking customized solutions or personalized experiences that cater to their unique requirements. Exploring potential solutions during the purchase cycle allows customers to make more informed decisions and choose the best option that aligns with their needs and preferences.

Assessing Financial Implications

Assessing the financial implications is crucial in the purchase cycle as it helps individuals and businesses make informed choices. Customers can evaluate their choices' financial feasibility and long-term implications by analyzing the potential costs, return on investment (ROI), and budget impact of a purchase decision.

When considering a purchase, it is important to understand its potential costs. This includes the initial purchase price and additional expenses such as maintenance, repairs, and upgrades.

By assessing these costs, customers can determine whether the product or service fits within their budget and if it provides value for money. Analyzing the ROI is equally essential.

Customers need to consider the potential return or benefit they will receive from the purchase. This could be in the form of increased productivity, cost savings, or revenue generation. Customers can prioritize their purchases and allocate resources by understanding the potential ROI.

Furthermore, assessing the budget impact helps individuals and businesses manage their finances effectively. It allows them to prioritize spending and ensure the purchase aligns with their financial goals and objectives. Careful budgeting prevents overspending and helps avoid unnecessary debt.

Assessing financial implications during the purchase cycle is crucial for making informed choices. It allows customers to evaluate potential costs, analyze ROI, and consider the budget impact. By doing so, individuals and businesses can make financially sound decisions and achieve their desired outcomes.

Seeking Approval from Key Stakeholders

Seeking approval from key stakeholders is a critical step in the purchase cycle. These stakeholders play a significant role in decision-making processes and have the power to approve or reject a purchase. To ensure a successful approval, it is crucial to identify and engage with these stakeholders effectively.

Firstly, it is important to identify the key stakeholders involved in the purchase decision. These stakeholders include managers, executives, department heads, and external parties such as suppliers or partners. Understanding their roles, responsibilities, and interests is essential in the approval process .

Once the stakeholders are identified, the next step is to engage with them. This involves creating a clear and concise proposal outlining the purchase's benefits and value. The proposal should address any potential concerns or objections and highlight how the purchase aligns with the organization's objectives.

Effective communication is key when engaging with stakeholders. It is important to tailor the message to each stakeholder, addressing their needs and priorities. Building relationships with stakeholders through regular communication, meetings, and updates is crucial in gaining their support and trust.

During the approval process, it is important to be responsive and address any questions or concerns raised by stakeholders promptly. This shows a commitment to transparency and highlights the effort to ensure a successful purchase.

Seeking approval from key stakeholders requires a strategic approach that involves identifying, engaging, and building relationships with these individuals. Effective communication throughout the process is crucial in gaining their approval and support.

Drafting a Request for Proposal (RFP)

Drafting a Request for Proposal (RFP) is an essential step in the procurement process. The purpose of an RFP is to outline the organization's procurement requirements and attract potential suppliers to submit comprehensive proposals.

A well-crafted RFP includes key elements such as the project scope, desired outcomes, and the period of time it will take. It should clearly articulate the organization's expectations , budget limitations, and any specific requirements.

Providing these details helps potential suppliers understand the project's parameters and enables them to tailor their proposals accordingly.

The organization can ensure potential suppliers address relevant aspects in their proposals by including specific project requirements . This could include details about the desired product or service specifications, delivery timelines, quality standards, and other critical considerations for the project's success.

Moreover, clearly defining the budget and expectations in the RFP helps potential suppliers understand the financial constraints and desired outcomes. This information enables them to evaluate their capabilities, resources, and suitability for the project before submitting proposals.

The RFP serves as a communication tool between the organization and potential suppliers . It allows for a fair and transparent evaluation process by establishing a clear framework that all suppliers can follow. An effective RFP helps the organization attract qualified suppliers and select the most suitable one for the project's success.

Supplier Selection Process

The supplier selection process is a critical component of the procurement cycle. It involves identifying, evaluating, and choosing suppliers who meet the organization's requirements for goods or services.

This process is crucial in ensuring the organization works with reliable and competent suppliers , contributing to its success. The supplier selection process involves various stages, including market analysis, request for proposal (RFP), vendor evaluation, and ultimately choosing the most suitable supplier.

It requires a comprehensive assessment of potential suppliers based on their performance, capacity, pricing, delivery times, and overall suitability for the organization's needs.

Organizations can establish strong relationships, optimize procurement processes, and achieve improved cost, quality, and customer satisfaction by carefully selecting suppliers.

Establishing Criteria for Supplier Selection

Establishing criteria for supplier selection is a crucial step in the procurement cycle. The procurement team initiates a thorough investigation to ensure the right suppliers are chosen. This involves carefully assessing the business requirements and seeking input from all stakeholders.

Firstly, the procurement team analyzes the organization's specific needs and identifies the essential criteria that any potential supplier must meet. This includes product quality, delivery times, pricing, and compliance with regulations. The team can objectively evaluate and compare each supplier by determining these criteria.

Next, the team seeks input from all relevant stakeholders , including end-users, finance, and operations. This helps to ensure that the selected supplier aligns with the organization's broader goals. Stakeholder input can provide valuable insights into specific requirements that may not be immediately apparent to the procurement team.

Establishing criteria for supplier selection requires a systematic approach. The procurement team conducts thorough investigations, compares business requirements with vendor proposals, and seeks stakeholder input.

Issuing an RFP to Potential Vendors/Suppliers

When an organization seeks to procure goods or services, one effective approach is issuing a Request for Proposal (RFP) to potential vendors or suppliers. An RFP is a document that outlines specific details of the procurement requirements and invites suppliers to submit their bids.

Like a job advertisement, the RFP includes the budget, expectations, and project requirements. It provides a clear framework for potential vendors to understand the organization's needs and determine if they have the necessary resources and capabilities to meet them.

Issuing an RFP is particularly useful when evaluating purchases at a high level, sourcing strategic suppliers, or procuring goods or services for a complex project. It allows organizations to gather comprehensive information from multiple vendors, enabling them to compare and evaluate proposals in a structured manner.

By issuing an RFP, organizations can attract a pool of potential vendors who are qualified and interested in providing their goods or services. This process facilitates transparency, fairness, and competition among suppliers, ultimately helping organizations make informed and beneficial procurement decisions.

Evaluating Responses and Shortlisting Vendors/Suppliers

Once the RFP responses are received, the procurement team begins evaluating and shortlisting vendors or suppliers. This step is crucial in ensuring the organization selects the most suitable partner for their project or procurement needs.

The procurement team starts by reviewing the RFP responses submitted by the vendors. They carefully assess each response, considering the vendor's qualifications , experience, capabilities, and proposed solutions. The team scores each response based on predefined criteria to create an objective evaluation process.

To ensure a thorough evaluation, the procurement team engages stakeholders from various departments or teams involved in the project. This allows for a comprehensive assessment of the vendor's fit within the organization's needs and goals. The input from stakeholders helps in making a well-rounded evaluation of each vendor's proposal.

Sometimes, the procurement team may require supplementary information from the shortlisted vendors. This could involve requesting additional details or clarification on certain aspects of their proposals. The purpose is to gather any missing information necessary for making an informed decision.

Performing Market Analysis and Due Diligence Checks on Selected Vendors/Suppliers

Performing market analysis and conducting due diligence checks on selected vendors/suppliers is crucial for making informed procurement decisions. This process involves gathering and evaluating relevant information to assess the suitability and reliability of potential vendors/suppliers.

Market analysis involves analyzing industry trends , competitor performance, and customer demands to understand the market landscape and identify potential vendors/suppliers. This analysis helps in determining the viability and competitiveness of vendors/suppliers in meeting specific procurement needs.

Due diligence checks involve evaluating vendors/suppliers based on their financial stability, reputation, legal compliance, and past performance. This includes conducting background checks , reviewing references, verifying certifications, and assessing financial statements.

The procurement team reviews and evaluates the data gathered from the Request for Proposal (RFP) process with the help of stakeholders. Stakeholders from various departments or teams are engaged to provide their expertise and perspectives.

They review the RFP responses, score each response based on predefined criteria, and provide insights into the vendor's fit within the organization's needs and goals. This collaborative approach ensures a comprehensive evaluation of the vendors/suppliers.

The procurement team may request additional information from the shortlisted vendors during the evaluation process. This could involve seeking clarification on certain aspects of the proposals or asking for supplementary details.

The purpose is to gather any missing information necessary for making an informed decision. This additional information aids in evaluating the vendor/supplier's capabilities , potential risks, and compatibility with the organization's requirements.

Negotiating Terms, Conditions, Prices & Delivery Times with Selected Vendors/Suppliers

After evaluating, the procurement team selects the most suitable vendors/suppliers to negotiate the contract. This crucial stage in the procurement cycle involves negotiating terms, conditions, prices, and delivery times with the selected vendors/suppliers.

Contract negotiation is essential as it allows both parties to reach a fair agreement that addresses their respective needs and interests. It helps establish clear expectations, minimize risks, and ensure a mutually beneficial relationship.

Effective negotiation can lead to cost savings, improved terms, and increased value for the organization and the vendor/supplier. During the negotiation process, key details are discussed and finalized. These include payment terms, contract length, delivery times, vendor performance expectations, and warranties provided.

Negotiating payment terms ensures both parties are comfortable with the agreed-upon payment schedule and methods. Contract length determines the partnership's duration and allows flexibility to adapt to changing business needs.

Delivery times are negotiated to meet the organization's requirements and optimize supply chain efficiency. Vendor performance expectations are defined to ensure quality, timely delivery, and adherence to agreed-upon standards. Lastly, warranties provided by the vendor/supplier are discussed to address any potential issues or defects.

Frequently Asked Questions

What is the purchase cycle.

The purchase cycle refers to a buyer's step-by-step process when purchasing, from identifying a need to evaluating suppliers, negotiating contracts, and placing the order.

What are the stages involved in the purchase cycle?

The purchase cycle typically consists of various stages, including identifying the need, conducting market research, vendor selection, negotiation and contracting, order placement, delivery, and supplier performance evaluation.

How long does the purchase cycle typically take?

The duration of the purchase cycle can vary depending on the complexity of the purchase, the number of suppliers involved, and the organization's internal processes. It can range from a few days for routine purchases to several months for more significant procurement initiatives.

What factors should I consider when selecting potential suppliers?

Factors such as supplier reliability, quality of products or services, price competitiveness, delivery capabilities, past performance, financial stability, and alignment with your organization's values and goals should be considered when selecting potential suppliers.

How important is contract negotiation in the purchase cycle?

Contract negotiation is crucial as it helps establish clear expectations, minimize risks, and ensure a mutually beneficial relationship with the selected vendor. It allows both parties to reach a fair agreement on payment terms, delivery times, performance expectations, and warranties provided.

How can I optimize the procurement process to reduce the purchase cycle time?

Streamlining the procurement process can be achieved through procurement software, effective communication with suppliers, automation of repetitive tasks, proper planning and organization, and continuous evaluation and improvement of the purchasing process.

What is the procurement department's role in the purchase cycle?

The procurement department plays a critical role in managing the purchase cycle. They are responsible for vendor selection, negotiation, and contracting, ensuring timely delivery, monitoring supplier performance, and optimizing the procurement process to meet the organization's needs.

How can I ensure a smooth delivery process during the purchase cycle?

To ensure a smooth delivery process, it is essential to communicate your requirements to the supplier and establish a realistic period of time for delivery. Monitor progress, promptly address any issues or delays, and maintain a good relationship with the supplier.

What should I consider when evaluating supplier performance in the purchase cycle?

Factors such as product or service quality, adherence to delivery schedules, responsiveness to inquiries or issues, communication effectiveness, and overall customer satisfaction should be considered when evaluating supplier performance.

How can I improve the purchase cycle to achieve better outcomes?

To improve the purchase cycle, organizations can focus on optimizing procurement processes, building strong relationships with vendors, leveraging technology, conducting regular market analysis, aligning procurement strategies with business goals, and continuously evaluating and improving supplier performance.

Stay Ahead of the Curve: Harnessing the Potential of Automated Reporting

Amazon E-commerce: From Bookseller To Global Retail Giant

The Power of Persuasion: Understanding the Psychology of Selling

Boost Your Income: Top Traffic Monetization Tips

Procurement and Purchasing

Procurement cycle guide: Stages & best practices explained

Colin Glazier

February 1, 2024

March 19, 2024

Managing business spend can be complicated, but it doesn’t have to be.

Modern businesses have evolved a tested-and-true method for ensuring goods and services are considered, sourced, acquired, and paid for in a transparent and measurable way.

This is the procurement cycle —an essential operation embodying the systematic approach to purchasing that businesses need to consider for an efficient and effective acquisition of goods and services.

In this guide , we’ll demonstrate the path towards a streamlined procurement process, emphasizing how standardization can ease what can otherwise be an overwhelming task.

By the end, you'll grasp the fundamental aspects of the procurement cycle, be able to distinguish between different types of procurement, and learn why this cycle is pivotal for every business, irrespective of scale.

By the end, you'll grasp the fundamental aspects of the procurement cycle, be able to distinguish between different types of procurement, and learn why this cycle is pivotal for every business, irrespective of scale.

You’ll also find out how solutions like Zip can revolutionize this vital process.

Let’s dive in!

What is a Procurement Cycle?

The procurement cycle—also referred to as ‘the procurement process’—encompasses the entirety of activities involved in the acquisition of goods and services—from initially identifying needs to the final payment, and subsequent record-keeping.

Tailored to align with an organization's unique needs and operational demands, this cycle ensures that resources are acquired in a timely, cost-effective, and compliant manner, setting the foundation for a business's operational efficiency and financial health.

Procurement Cycle guide: 7 steps explained

Each organization’s procurement process may differ, but there are common steps that provide a framework for efficient and effective procurement.

Let’s explore these steps and their significance in the procurement cycle.

Step 1. Define needs

This is where the procurement cycle begins.

Start by accurately identifying exactly which goods or services are required to move forward with your company’s business needs. Before making any purchase request, consider the price, quality, quantity, and cadence required.

This will all inform the later stages of the cycle—without a full understanding of the needs of your departments with a clear list of requirements, you may find yourself stuck in the later stages of this process.

Know what you need, and why you need it. That’s the bottom line.

Step 2. Create a purchase requisition

Once needs are defined, you’ll want to ‘create purchase requisition’. This document serves as a formal request for the needed goods or services and typically includes specifications, quantity, and budget.

The creation of a purchase requisition will help maintain an organized and controlled procurement processes, and ensure that purchases are pre-approved and aligned with the organization's broader needs and policies.

Step 3. Purchase requisition review and approval

The third step involves the review and approval of this purchase requisition. This acts as a checkpoint for budget compliance and need verification, preventing unnecessary or extravagant expenditures.

Approvers will assess the requisition for its necessity, cost-effectiveness, and alignment with organizational goals, providing an additional layer of oversight.

Step 4. Vendor selection

The Vendor selection stage is a pivotal moment during the procurement cycle. Who are you going to work with?

This process involves evaluating and choosing potential suppliers for your needs, based on criteria you hopefully established during Needs Identification—things like the price you’re looking for, the quality you require, and other reliability and service metrics.

For more information about vendor selection and strategic sourcing, check out Zip’s Guide: ‘ Sourcing Strategies Beyond the RFP: Tactics to Drive Savings and Win Bids ’.

Step 5. Create and approve purchase order (PO)

After selecting a vendor, you’ll need to create and approve a purchase order. The PO formalizes the transaction, outlining the specifics of the order, including quantities, descriptions, prices, and contract terms.

Remember, that the PO serves as a legally binding agreement between the buyer and the supplier, and its approval is essential in order to move forward with the procurement cycle.

Here’s a more detailed guide on accounts payable workflows and automations that can reduce bottlenecks and save your finance team valuable time.

Step 6. Order management

Order management involves overseeing the order's delivery and ensuring that it meets the agreed-upon contract terms.

Maintaining the timeline, quality control, and compliance with the contract is an essential component of the procurement cycle. Effective order management helps in identifying and resolving discrepancies early, ensuring smooth operation and satisfaction on both ends.

Step 7. Invoice review and payment

Once all services items are rendered, the final step in the procurement cycle is the review and payment of the invoice.

The purchasing process ensures that the goods or services received are in line with the order and that the payment terms agreed upon are honored. Timely and accurate payment fosters a good relationship with suppliers and may pay dividends in the future, when you one day perhaps work together again!

Follow up: store and update records

Finally, storing and updating records is an essential step for maintaining transparency and accountability in the procurement process. It involves keeping detailed records of all transactions, contracts, receipts, and communications. This practice not only aids in future audits and compliance checks but also provides valuable data for analyzing and improving the procurement process.

What's the difference Between Direct, Indirect, and Services Procurement?

Understanding the nuances between indirect, direct, and services procurement is important for businesses aiming to optimize their purchasing strategy. Each plays a unique role in the overall strategic procurement landscape, impacting everything from cost management to supplier relationships.

Direct procurement

This refers to the acquisition of goods and materials that are directly incorporated into the products being manufactured. For instance, a smartphone company purchasing microchips or a car manufacturer buying steel.

Direct procurement is closely tied to the company's core business activities and has a direct impact on the production process and the end product's quality. Since these purchases are often large in scale and strategically important, they're typically planned and forecasted with precision, involving long-term supplier relationships.

Indirect procurement

In contrast, indirect procurement involves purchasing goods and services that support a company's operations but are not part of the final product. This can include office supplies, software licenses, or janitorial services.

Although these purchases might seem less critical at first glance, they are essential for day-to-day business operations. Indirect procurement tends to be more unpredictable and varied, requiring a more flexible approach to manage diverse suppliers and spend categories.

Services procurement

This is a subset of indirect procurement but deserves a special mention due to its growing importance. It involves acquiring services rather than goods, such as consulting, legal services, or marketing.

Services procurement poses unique challenges, such as evaluating the quality of service, managing service delivery, and ensuring value for money. It requires a nuanced approach, focusing on supplier capabilities, service level agreements, and ongoing relationship management.

Understanding these distinctions is key for Chief Procurement Officers and procurement teams. It allows for more targeted strategies, effective cost management, and better alignment with the company's overall goals.

Why is the Procurement Cycle important?

The procurement cycle is the backbone of any business's operational and financial health, especially if trends in the market continue.

In 2023, the Hackett Group reported a 10.6% increase in procurement requirements globally , underscoring the need for a well-trained team that knows how to administer procurement processes for operations.

The procurement cycle, when optimized and adhered to, can do more than just help businesses secure the best quality goods and services at the most competitive prices.

It can help build stronger partnerships with suppliers, which can be hugely beneficial for long-term success and supply-chain savings. It can also boost employee productivity by streamlining processes, allowing the team to spend less time on administrative tasks, and more on strategic activities that add measurable value to the business.

By understanding and optimizing the procurement cycle, businesses can position themselves for success in an increasingly competitive and complex business environment.

How do you improve your Procurement Cycle? Best practices and strategy

Improving your procurement cycle is not just about streamlining operations; it's about leveraging data and technology to make informed decisions that drive efficiency and cost savings. Here's how you can enhance your procurement management, supported by industry statistics and insights:

1. Digitize manual processes

In case you haven’t already— it’s time to digitize.

A study from The Hackett Group found that digital transformation can reduce procurement costs by up to 45% and increase efficiency by 30-50% .

Implementing electronic purchase orders and invoices are optimizations that can significantly speed up approvals and payments, streamlining the procurement workflow for all stakeholders involved.

2. Utilize automation

Automation plays a pivotal role in enhancing procurement processes. According to McKinsey , companies that automate their procurement processes can see up to a 3% savings on total spend annually.

Procurement software like Zip automatically generates purchase orders and software for vendor evaluations can free up your team’s time for more strategic decision-making.

3. Standardize your procurement cycle guide

A standardized procurement process ensures consistency and efficiency. Creating a clear guide that outlines each step, from requisition to payment, sets expectations and minimizes confusion.

4. Improve procurement data visibility

Visibility into procurement data is helpful not just for making better decisions, but also informing stakeholders about the status of orders, and if any action needs to be taken.

A centralized AI-powered procurement platform like Zip can also identify spending patterns, evaluate supplier performance, and highlight areas for improvement and cost savings—with real-time insights and alerts.

5. Track actionable KPIs and insights

Identifying and tracking key performance indicators (KPIs) can provide actionable insights into the efficiency and effectiveness of your procurement process.

Metrics such as cost savings, spend under management, and supplier performance can help in assessing the procurement cycle's health and pinpoint areas for improvement. Regularly review these KPIs to ensure that your procurement strategy remains aligned with your broader business goals.

6. Centralize procurement data and documents

A centralized repository for all procurement-related data and documents simplifies access and management, ensuring that all your contracts, purchase orders, supplier information, and performance metrics are all located within a single source of truth.

What are the Top Challenges for the Procurement Cycle?

The procurement cycle, even though it's designed to maximize efficiency in operations, is not without its challenges. Understanding the pain points is important for organizations looking to streamline their procurement processes and improve overall efficiency.

Let’s explore the most common challenges encountered in the procurement cycle.