Supplier Evaluation — Everything A Procurement Professional Should

What is supplier evaluation, the importance of supplier evaluation, the benefits of conducting an evaluation of suppliers, supplier performance evaluation checklist, frequently asked questions.

- Supplier evaluation is an instrument used to measure the effectiveness and suitability of suppliers to your company.

- A regular supplier evaluation has many benefits, including your supplier’s improvement in performance.

- Supplier evaluation also helps companies choose and select the best partners.

1. Enhance the visibility of the supplier’s performance

2. mitigate risks, 3. improve supplier performance, 4. align customer and business practices, 1. establish performance indicators.

- Price – The organization can create a win-win situation with vendors who are able and willing to lower their prices. By lowering their prices, the organization would want to deal with them often.

- Cost – This can either be monetary or non-monetary when dealing with suppliers. It includes peripheral costs that are associated with movement, packaging, delivery, and disposal

- Quantity – The organization can also consider the comparison between quantities ordered and received. Sometimes, the vendor will send a notice to confirm and explain anomalies in the delivery.

- Quality – The organization must inspect the delivered goods to check any visible product defects, rejections, and returns.

- Service – This includes indicators such as the response time of resolving issues and client satisfaction engagement.

- Delivery – This indicator focuses on the timeliness of the order process and the pre-delivery waiting period.

- Payment terms – A fast payment method and terms are preferable to organizations than a slow payment process.

- Financial health – Suppliers that have good financial health can provide for the needs of an organization much better.

- Compliance – You need to know how compliant your suppliers are in terms of their taxes, contracts, and procedures.

2. Classify suppliers

3. centralize the data, 4. collaborate with suppliers for feedback, 5. create an actionable plan, why is it needed, what are the indicators that the organization must include in its evaluation, about the author.

Supplier Evaluation - How To Evaluate Your Suppliers

Table of contents

1, What is supplier evaluation?

2. How do you evaluate a supplier?

3. How to evaluate supplier performance template

4. How to perform supplier evaluation with Prokuria

In case you don't have time to read the whole article, here is a short video summary that contains the key points:

Most organizations tend to leave supplier management to chance, meaning they have no idea how their suppliers are performing and whether they are profitable or at risk.

But what isn’t measured cannot be improved. And awarding additional business based on suppliers meeting performance goals can bring dramatic results.

There are 2 main reasons you should perform supplier evaluation :

For existing suppliers, it can help you uncover and remove hidden waste and costs and achieve sustainable procurement;

For new suppliers, it can set a threshold that can lead to higher-quality results.

When organizations have a good understanding of their suppliers’ capabilities and performance levels, they can better plan new products and services. But before we go deeper into why and how to perform supplier evaluation, let’s first define what it means.

What is supplier evaluation?

Supplier evaluation is the process of assessing and approving potential suppliers through quantitative and qualitative assessments. This is done to ensure you only work with the best-in-class suppliers available.

The same process can also be applied to current suppliers to measure and monitor their performance to reduce costs, mitigate risk, and drive continuous improvement.

There are several ways you can carry out a supplier assessment - questionnaires, scorecards, site visits, and third-party standard certifications. Or you could use a supplier management platform like Prokuria.

The most important thing you should remember is that you should perform a supplier evaluation regularly (at least 2 times a year, but best-in-class organizations perform an evaluation every 3 months). Each time, you should check whether your suppliers get better scores than they previously got.

How do you evaluate a supplier?

Every organization is different. So, to ensure you’re evaluating suppliers as fair as possible, you must first determine what matters most to you. What are you looking for in a business partner? Quality products? A good relationship with you?

Once you write that down (using a supplier scorecard), it will be easier to decide which suppliers meet your criteria and which don’t.

Here’s what we think you should consider:

Fairness : when negotiating, do your suppliers abide by the highest standards of ethical business practices? Do they display fair play behavior to all stakeholders, including their own customers, employees, suppliers, and community?

Customer focus : are they dedicated to anticipating and meeting the expectations and requirements of your customers? A good business partner should have a thorough understanding of market trends and opportunities and act in your best interest.

Team spirit : do they value diversity? Do they advocate for trust, respect, mutual commitment, and boundaryless thinking?

Business approach : do their business objectives align with yours? Do they leverage their expertise to grow both their business and yours?

How to evaluate supplier performance template

Even though the information we described above is important, it’s not easily quantifiable - it’s more helpful for establishing a good business relationship with suppliers .

For a more objective approach, here’s a template of what criteria to use for supplier evaluation:

Production capacity

Environmental impact

Compliance to specifications

Meets specification requirements

Meets standards

Customer service

Policy and practice

Surveys customers

Systems to measure customer satisfaction

Backup and advice

Quality of deliverables

Certification

Documented system

Staffing structure

Availability of experienced staff

Experience in the industry

State of technology

Past performance

Previous experience

Customer recommendation

Leading technology

Financial viability

Does the supplier satisfy key financial ratios for the industry?

Can the supplier provide full financial disclosure?

Risk and insurance

Adequate insurance

Allocate and acceptance of risk

Legal aspects

Complies to the terms and conditions

Conflict of interest (existing, potential, or perceived)

Legal proceedings related to contractual issues (past or present)

The total cost of ownership

Ability to propose an innovative financial approach (gain-sharing, etc.)

Price breaks and quantity discounts

Satisfies best value analysis

Maintenance costs

Financial review

Lease vs. Buy

Foreign exchange

Payment terms

Business justification

Net present value analysis

Payment methods (i.e., EDI, etc.)

How to perform supplier evaluation with Prokuria

The template above enables you to perform an extensive analysis of your suppliers. However, to compare the results, you’ll need appropriate tools - if you have hundreds of suppliers, it would be almost impossible to perform supplier evaluation in an Excel spreadsheet .

This is where supplier management software like Prokuria can help. Our platform enables you to easily evaluate your suppliers and maintain a scorecard . Here’s how it works:

Fill in the “Score” column by entering a valid number in each cell that reflects the number of points awarded for each criterion;

A final score will be calculated for each supplier, based on the weight each criterion holds;

You can then export your scorecard as an Excel file and save it for future comparisons.

Evaluate your current suppliers

Try prokuria for free today.

- Supplier management

Related Posts

Feeling Lost in Procurement? These Powerful Frameworks Can Steer Your Small Business to Success

Applicable Management Strategies for Procurement in Small to Medium-Sized Businesses

Mastering Negotiation Techniques in Procurement: Practical Models for small to Medium-Sized Businesses

Procurement 101: Supplier Evaluation – How it works and why it’s important

Table of contents.

What is Supplier Evaluation?

Supplier evaluation is the systematic assessment of a supplier’s performance and capabilities. It is a crucial process for businesses to ensure they are working with partners who can meet their needs and expectations. Evaluating suppliers thoroughly allows companies to identify the best partners, while weeding out poor performers. This leads to reduced costs, improved quality, and better customer satisfaction.

The importance of supplier evaluation cannot be understated. It provides the evidence needed to make sound sourcing decisions. Companies rely heavily on suppliers for raw materials, components, logistics, and other services vital to their operations. Choosing the wrong partners can result in compromised quality, missed deliveries, higher prices, and risks to the supply chain. Robust evaluation minimizes these hazards. It also uncovers opportunities for improving supplier relationships and leveraging their capabilities for competitive advantage. The time invested in assessment today saves money and headaches down the road.

When to Evaluate

The main times a supplier should be formally evaluated include:

- Initial Selection – When first selecting suppliers, request information and assess their capabilities against your requirements. Set evaluation criteria and review proposals from potential suppliers to determine the best fit.

- Routine Monitoring – Monitor supplier performance at regular intervals as part of ongoing supplier management. Gather performance data and conduct evaluations to identify improvement opportunities.

- Contract Renewal – Re-evaluate suppliers when contracts are up for renewal. Review their performance over the contract period and determine if they still meet requirements. Renegotiate terms or consider other suppliers.

- New Product/Service – When outsourcing a new product or service, existing suppliers should be re-evaluated along with any new supplier candidates. Ensure they can meet the new requirements.

What to Evaluate

When evaluating suppliers, there are several key factors to consider:

- How do the supplier’s prices compare to competitors? Are volume discounts available?

- Is the pricing structure fair and reasonable? Are there hidden fees?

- Does the pricing align with the value delivered?

- Does the supplier consistently meet quality specifications?

- Do they have quality control procedures in place?

- Can they provide testing reports or quality certifications?

- What is their track record with quality and defects?

- Can the supplier deliver on-time, with the right quantities and to the right locations?

- Do they have the capacity to meet demand fluctuations or surges?

- What is their policy on managing backorders or stock-outs?

Customer Service

- How responsive is the supplier to inquiries, issues, and requests?

- Do they provide training or support as needed?

- Will they customize products or services to meet your needs?

Financial Stability

- Does the supplier have solid financials and good credit standing?

- Are they able to sustain and invest in the business relationship?

- What contingencies exist if they go out of business?

Capabilities

- Does the supplier have the technical expertise to understand your needs?

- Can they deliver ongoing innovation and process improvements?

- Do they have resources dedicated to your business?

- Are they keeping pace with changes in the market or industry?

Evaluating these key factors will provide a comprehensive view of supplier performance and enable informed decisions when managing suppliers.

Methods of Evaluation

Organizations use a variety of methods to evaluate suppliers and their performance. Some key methods include:

Scorecards are a systematic way of assessing suppliers on a range of criteria using a numeric rating system. They allow companies to benchmark supplier performance over time. Key metrics on a supplier scorecard may include quality, delivery, cost, customer service, and management factors.

Site Visits

Visiting a supplier’s production facilities first-hand offers valuable insights into their operations, capabilities, processes, and culture. Site visits allow for direct observation, interviews with staff, and review of practices. They can help verify if suppliers meet required standards and specifications.

Surveys with quantitative and qualitative measures can provide feedback from various stakeholders on how they perceive suppliers. Customer surveys can assess their satisfaction with supplier performance. Internal user surveys can judge the supplier relationship experience. Supplier surveys allow self-assessment.

Product Testing

Obtaining samples of a supplier’s products or services and directly testing or inspecting them reveals if they meet requirements. This can include functionality, quality assurance, safety compliance, sensory evaluation, and more. Destructive testing puts products under stress to test limits.

Questionnaires

Supplier questionnaires cover a wide span of topics to collect standardized data on capabilities, processes, certifications, costs, management, and risks. They provide snapshots of suppliers for comparison and analysis. Questionnaires work well for assessing potential new suppliers.

Key Performance Indicators

When evaluating suppliers, there are 5 key performance indicators to consider:

- Product quality – Does the product meet specifications and quality requirements? Is the quality consistent?

- Process quality – Does the supplier have quality control procedures in place? What is their defect rate?

- Quality certifications – Do they hold any ISO or industry-specific quality certifications?

- On-time delivery – How often do they deliver orders on time, in full?

- Flexibility – Can they handle rush orders or fluctuations in demand?

- Lead times – How long are their average lead times from order to delivery?

- Pricing – How do their prices compare to market rates? Do they offer discounts?

- Total cost – Consider not just unit price, but total cost of acquisition.

- Open book pricing – Will they share cost breakdowns if requested?

Responsiveness

- Communication – How quickly and thoroughly do they respond to inquiries and issues?

- Customer service – How knowledgeable and helpful is their customer service team?

- Agility – How quickly can they respond to changing needs or priorities?

- Regulatory – Do they comply with all relevant regulations and standards?

- Contracts – Do they adhere to contact terms and conditions?

- Ethical practices – Do they reflect your organization’s values?

- Reporting – Do they provide all required compliance documentation?

Weighing Criteria

When evaluating suppliers, it’s important to prioritize criteria based on your company’s specific needs and goals. A weighted scoring system can help quantify criteria and make comparisons between suppliers more objective.

- Identify the 5-10 most important criteria to evaluate (quality, cost, lead times, service, etc.). Rank or weight them based on priority.

- Develop a scoring system for each criterion. For example, use a scale of 1-5 or 1-10. Make sure the scale has clear definitions.

- Multiply the score by the weight to get the weighted score.

- Add up weighted scores to get the total for each supplier. Higher scores indicate better fit and performance.

- Focus comparisons on suppliers with top scores. Go with the one aligned closest to your weighted criteria.

- Re-evaluate criteria weights periodically to realign with evolving needs. Adjust scoring as needed.

By weighting and quantifying supplier criteria, you gain data-driven insights into which suppliers best fit your business priorities. A systematic process also provides objectivity. Just be sure to focus on key factors so the system doesn’t get too complex.

Conducting Assessments

Carefully managing the evaluation process helps ensure fair, objective, and constructive supplier reviews. Here are some best practices:

- Form a review team – Assign a cross-functional team representing key departments to evaluate each supplier. This provides balanced input.

- Gather data – The team should use performance reports, scorecards, surveys, and other sources to collect feedback on the supplier’s criteria.

- Normalize scores – Weighting criteria and standardizing scoring normalizes results across suppliers. This minimizes individual reviewer bias.

- Provide feedback – Review results with each supplier in a discussion. Highlight strengths, improvement areas, and performance goals.

- Track actions – Follow up on issues, measure progress over time, and document supplier responses. This closes the loop.

- Focus on facts – Reviews should be data-driven, not based on opinions or hearsay. Quantify and document assessment factors.

- Emphasize two-way communication – Encourage supplier participation to understand their challenges and perspectives. Make it a continuous improvement process.

Conducting methodical, fair, and collaborative assessments ensures an objective supplier evaluation program that builds partnerships.

Managing Performance

Once evaluations are complete, it’s important to have a plan for addressing any issues or opportunities identified. Here are some best practices:

- Corrective Actions – If a supplier scores poorly in certain areas, corrective actions should be put in place. This may involve requiring the supplier to undergo additional training, improve quality control processes, increase staffing, or make other changes to resolve the deficiencies uncovered in the evaluation. Agree on an improvement plan with clear timelines.

- Improvement Plans – Even well-performing suppliers can benefit from improvement plans to encourage continuous enhancement. Collaboratively develop a plan to boost capabilities in areas like responsiveness, reporting, sustainability practices, or other metrics. Offer support and resources to aid the supplier in leveling up.

- Incentives – Offering incentives to top-performing suppliers can further motivate them to go above and beyond. Consider providing bonuses, increased business, preferential commercial terms, public recognition, or access to new opportunities as rewards for exceeding expectations.

- Recognition – Positive reinforcement goes a long way. Be sure to recognize and reward excellent suppliers. Feature top partners in company publications, invite them to events, ask them to speak at conferences, or find other ways to recognize suppliers who demonstrate exemplary performance.

Proactively managing supplier performance helps strengthen the relationships and results. Ongoing monitoring and dialogue ensures both parties are aligned on priorities and working collaboratively towards shared objectives.

Supplier evaluation is an essential process for any organization that relies on external suppliers for products or services. As summarized in this article, there are several key reasons why conducting regular supplier evaluations is important:

By implementing a robust supplier evaluation process, you can make data-driven decisions that optimize supplier relationships and performance. This delivers tangible benefits like cost savings, risk reduction, quality improvements, and better oversight of your supply chain. Supplier evaluations are not just a nice-to-have, but a must-have strategic practice for any business involved in sourcing.

Ready to see CADDi Drawer in action? Get a personalized demo.

Related resources.

Departments

More topics from Droppe

Supplier evaluation and assessment explained: what, how, and why.

- 7 minutes to read

- July 23, 2024

Introduction:

In procurement, supplier evaluation and assessment assist organisations verify prospective suppliers and review current partnerships. Competitiveness depends on these judgements in fast-paced sectors. A low-risk, high-quality supplier portfolio helps firms optimise resource utilisation, improve procurement , and form long-term, mutually beneficial partnerships. This article discusses supplier evaluation and assessment’s relevance, advantages, and best practices.

What’s Supplier Evaluation?

Supplier evaluation in procurement involves formal assessments of suppliers’ performance against several criteria to evaluate if they match organisational needs. The goal is to build a low-risk, best-in-class supplier portfolio.

Departments continuously evaluate suppliers as a pre-qualification phase in purchasing .

Hald and Ellegaard (2011) define supplier assessment as “the process of quantifying the efficiency and effectiveness of supplier action.”

In simple words, supplier assessment involves determining if a provider fits your business. Also considers your present supplier base to assess performance and find cost-saving, risk-mitigation, and continuous improvement opportunities. Thus, open and equitable alignment of objectives, data, and analysis with suppliers is the first step in effective supplier appraisal.

Importance of Supplier Evaluation

Every procurement organisation seeks to maximise resource use. To get the highest quality, affordability, flexibility, and dependability contracts, suppliers must be evaluated.

The supplier assessment process is difficult, but identifying low-risk, high-quality suppliers and long-term business connections is worth it.

Others benefits of supplier evaluation include:

- Risk mitigation: Careful supplier screening reduces regulatory, contract, and security risks connected with dealing with external systems.

- Improvements in supplier performance immediately affect procurement process performance. Supplier assessment and appraisal factors determine 57.1% of procurement performance (Murigi 2014). Since supplier evaluation encourages efficiency and innovation, suppliers enhance their operations. When firms base choices on supplier performance targets, the results are astounding.

- Cost reduction: Supplier assessment affects product quality and cost, thus it’s important for any company. Organisations benefit from a little cost and quality increase from supplier selection.

- Leveraged supply base: Evaluating supplier performance sets a benchmark, which improves results. It also allows firms establish goals and actions based on suppliers’ capabilities and performance.

- A quality criteria helps evaluate suppliers by encouraging them to increase efficiency and innovation. Supplier performance is crucial to a purchasing organization’s success. Also, the seller and customer must agree on their quality.

- Improved supplier relationships: Effective supplier management fosters communication, collaboration, and loyalty, which leads to long-term, mutually beneficial partnerships.

- Increased business results: Top suppliers allow you to offer higher-quality, cheaper products and services. You can better service consumers and increase sales and loyalty.

Evaluation of Suppliers

The supplier assessment process begins with assessing your company’s needs and creating a list of requirements to discuss with vendors. After that, a selection criterion is created to evaluate vendors, including a scoring method.

A market study determines the number of suppliers who will participate in the RFQ process. A small group of suppliers and an initial bidders’ list is a version of the second phase. The following providers meet the standards. Then, vendors on the list get an RFI requesting further information. The RFI asks if the firm is interested and gathers enough information to make a general assessment.

After receiving bids or RFIs, all corporate stakeholders assess providers. Results and discussions determine supplier selection.

Most procurement specialists agree there is no optimum supplier assessment method. So corporations try different methods to discover what works. The evaluation process reduces risks and maximises value for the procurement organisation, regardless of strategy.

It’s vital to note that supplier evaluation continues after selection. Once an association is formed, the supplier’s performance must be monitored. Ranking suppliers by metrics helps firms determine which ones are best and which need development.

Supplier Evaluation Criteria

Supplier evaluation involves qualitative and quantitative criteria. Creating uniform selection criteria and applying them to all case is insufficient.

Your company’s mission, vision, and business goals should guide supplier evaluation. We should also consider quality, pricing, financial integrity, corporate social responsibility, communication, and cultural convictions.

Your organization’s priorities must be considered while evaluating contractors and providers. For instance, a healthcare organisation must prioritise data security and regulatory rules over other issues.

However, corporations often face opposing concrete and intangible elements that make decisions difficult.

The supplier selection process must involve all essential firm stakeholders, such as procurement, engineering, logistics, manufacturing, etc. Stakeholders must agree on selection criteria. Doing so ensures each is weighted according to significance, corporate priorities, and strategy.

12 Supplier Evaluation Criteria

Effective supplier assessment criteria affect an organization’s buying performance.

Supplier assessment and appraisal criteria determine 57.1% of procurement process performance, according to Murigi (2014).

The most typical factors are materials supply, quality, pricing, financial status, communication, and technology. Many other characteristics may be more significant, depending on the method. Thus, creating an exclusive list is difficult.

Below are some factors an organisation may use to evaluate suppliers:

- Quality is a difficult notion to describe. IBM defined quality best for supplier assessment: “Quality means meeting customer needs. Quality products and services are when supplier and customer agree on needs and meet them.” Quality management includes department, supplier, and customer interaction. After setting quality standards, the manufacturing process must be organised to achieve and sustain them. To achieve this, quality management has four interdependent functions: defining standards, assessment, control, and assurance. An external assessment determines how well the procedures meet national and international standards. ISO-9000/9001 is an example.

- Price/Cost: Expectations include present and future cost needs, cost reduction, continual improvement, and overall cost (including acquisition, inventory, and disposal expenses).

- Performance Delivery: Guaranteed product delivery at the proper time and quantity. It entails reviewing customer orders, scheduling production, and determining the time needed to meet client expectations. Service includes following directions, managing complaints, convenience of business, and prompt response. All these variables make defining service criteria difficult.

Subjective judgements are used to evaluate suppliers’ services. This requires thoughts on assistance quality, supplier attitude, response speed, support personnel credentials, etc.

Most firms use a basic rating system of excellent, satisfactory, and bad for supplier service, with reasons.

- Financial Strength: Assessing a supplier’s finances. It implies determining if a provider can invest in resources, pay suppliers and workers, and satisfy debt and financial responsibilities. These elements are crucial to supply disruption.

- Lead-Time: The time between order and delivery is a dependability concern.

- Technical aptitude: This factor evaluates a supplier’s technical aptitude and capacity to follow progress.

- Flexibility: A supplier’s capacity to modify numbers and delivery periods to meet customer demands.

- Development considers innovation and improvement to enhance goods and save prices.

- The management approach is crucial for a corporation seeking long-term supplier partnerships. The crucial quadrant suppliers, who offer vital commodities in large quantities, usually form such agreements. Parties must agree on goals and measurements to start a partnership. If properly formed, such partnerships might lead to cost-saving and product-development collaboration.

- Geographic Location: Geographic closeness is significant since increasing distance might cause transport, logistical, and currency changes, reducing flexibility.

- Environmental Regulation Compliance: Supply chain partnerships increasingly ask suppliers to meet sustainability standards.

Finding the Key Supplier Evaluation Criteria

It advised organisations to categorise supplier selection criteria as follows:

Mandatory —To be on the bid list, suppliers must fulfil these requirements.

These are preferred , although a provider can still bid. Nevertheless, these factors will determine supplier selection.

Leading —limit concerns to a few. These difficulties will distinguish great vendors from the others. The supplier selection process should prioritise these problems.

5 Tips for Supplier Evaluation Success

- Procurement managers must develop scoring criteria to evaluate and choose suppliers for business and keep them on the authorised vendor list.

Supplier selection criteria vary. However, these requirements can conflict. For instance, cost and quality can conflict. Thus, factors must be weighted to determine which provider offers the best trade-off of all criteria. Use fewer critical criteria than a huge list, as each will count little in the final score.

- Since certain criteria are qualitative, evaluating them is challenging. More subjective and person-dependent factors. Cost is quantifiable, while product or service quality is qualitative. Not immediately measurable. In that instance, consider product rejection costs, post-sale services costs, etc.

- Companies struggle to manage hundreds of thousands of suppliers across functions. It may be addressed by building and administering a central supplier database. Ignite Procurement automates and centralises supplier data and analytics.

- Determine the evaluator. Procurement employees usually serve this role, however analysts are best for high-cost or difficult cases. A consultant may help with time-consuming tasks like research, preparing the RFP, and financial analysis, which the organisation may not have.

- Without a deadline, the final selection and recruiting process is tough.

Quick Supplier Evaluation Checklist

Supplier review is ongoing and keeps consumers and goals in mind. To ensure you evaluate vendors using best practices, check these steps:

- Check your supplier’s performance regularly.

- Set supplier assessment criteria, standards, methods, and procedures.

- Standardise your supplier evaluation using a form to make better, quicker, and more strategic judgements.

- Choose and classify suppliers depending on supplier assessment goals.

- Use statistics and facts in supplier interactions. Always communicate, especially with critical suppliers.

- Technology optimises information utilisation.

- Talk to your vendors often to improve suboptimal areas.

- Reevaluate supplier performance using your criteria.

- Do it again.

Conclusion:

Continuously creating criteria, analysing performance, and communicating with suppliers is key to supplier assessment. Best practises and digital technologies help organisations decrease risks, costs, supplier performance, and develop strategic alliances. A comprehensive supplier assessment improves procurement efficiency and the organization’s success and sustainability. The evaluation method is reviewed and updated to keep the supplier base current with the company’s goals and market expectations.

Share this article

Explore europe's widest catalogue.

Shipping Supplies

Safety Equipment

Food & Utensils

Cleaning & Hygiene Supplies

Tools, Tapes & Bolts

minutes to read

Types of Respirators: A Comprehensive Guide

How to Choose the Best Lab Safety Goggles: A Complete Guide

How to Choose the Best Anti-Fog Safety Goggles

Follow & Join

Sign up for the newsletters.

© 2023, Droppe Oy / 3130765-4

- There are no suggestions because the search field is empty.

Supplier evaluation: What is it, and how’s it done?

Don’t miss an article.

Your suppliers play an integral part in the success of your business. That makes it vital to be working with the right ones – and that’s exactly what supplier evaluation will help you achieve.

Supplier evaluation is about determining if your current or potential suppliers are the right fit for your business. It’s about ensuring that your supply chain is reliable, cost-effective and meets your expectations – all crucial aspects of running a successful business.

In this article, we’ll cover what supplier evaluation is, why it’s important and 6 steps to carry out an effective supplier evaluation.

What is supplier evaluation?

Supplier evaluation is an element of Supplier Performance Management . Essentially, it’s the process of evaluating and approving suppliers – both potential and existing – on elements such as quality, delivery, costs, services and innovation potential.

Businesses employ a variety of different supplier evaluation methods, including:

- Questionnaires

- Site visits

- Trial orders

The goal of supplier evaluation is to assess whether a current or potential supplier is a good match for your business. It allows you to create a best-in-class, low-risk portfolio of available suppliers.

In short, supplier evaluation helps you build lasting professional relationships with suppliers that you know you can rely on – a crucial aspect of running a successful business.

Why is supplier evaluation important?

It probably goes without saying that it’s important to know that you’re working with reliable suppliers. Still, there are many reasons why supplier evaluation is so integral to your success.

Let’s take a look at some of them:

- Quality assurance: If your products aren’t up to scratch, it can cost you dearly. Supplier evaluation helps you ensure that your suppliers consistently provide quality products. It minimises unnecessary costs, and it keeps your customers happy.

- Cost efficiency: Who doesn’t love saving money? Supplier evaluation helps you balance cost with quality and service, helping you find those hidden gems that offer the best value for money.

- Reliability: Imagine a world without supply hiccups. Evaluating suppliers enables you to minimise disruptions and ensure your operations run smoothly – what’s not to like?

- Risk management: No one likes a nasty surprise, and with supplier evaluation you can avoid them. Supplier evaluation helps you spot potential risks before they become big headaches, saving you valuable time and resources in the long run.

- Compliance: Evaluating suppliers allows you to keep things above board. It ensures your suppliers play by the rules, follow the law and keep things ethical. In other words, it lets you sleep easy – and the less stress, the better.

- Performance improvement: With clear benchmarks for supplier performance, you encourage your suppliers to constantly level up their game, inspiring excellence and innovation.

- Strategic relationships: Strong supplier relationships are a vital asset in the business world. Effective supplier evaluation can help you build rock solid professional relationships and boost your long-term success.

6 essential steps for effective supplier evaluation

.png?width=2500&height=1055&name=2024_0705_supplier_evaluation_SE_2%20(3).png)

Now that we’ve covered why supplier evaluation is so important, it’s time to get a better idea of what the process involves.

For that purpose, we’ve compiled a list of six key steps to carry out supplier evaluation effectively. Let’s get started.

1. Define your evaluation criteria

It probably goes without saying that to effectively evaluate your suppliers, you need to know what criteria you’re basing your evaluation on.

To help you define your evaluation criteria, here’s a list of important criteria to consider:

- Quality: What’s the supplier’s defect rate? Does the supplier comply with specifications and quality control processes? Assess their product quality to ensure it fits your standards.

- Cost: Does the supplier’s pricing structure work for you? Evaluate hidden costs, discounts and overall cost-effectiveness.

- Delivery: Make sure the supplier can meet your delivery requirements and that they’re reliable and fulfil orders on time.

- Financial stability: Check the supplier’s financial health – it’s important to ensure their operation is sustainable and supports your business as it grows.

- Service and support: If an issue pops up, you want suppliers who offer great customer service and technical support. Check how fast and how well they respond to problems.

- Compliance: The quality and cost effectiveness may be on point, but if the supplier doesn’t play by the rules, they’re no good. Make sure they comply with industry standards.

- Innovation: You want to build lasting relationships. Assess the supplier’s ability to innovate and improve – these qualities are vital for a long-lasting collaboration.

2. Develop a scoring system

Next, it’s time to create a scoring system based on the evaluation criteria you’ve defined. This’ll enable you to quantitatively evaluate each potential supplier, giving you a better idea of how they compare.

Assign scores to each criterion for the individual suppliers. Once that’s done, you can calculate the total score to rank each supplier. This way, you can quickly get an overview of what each supplier excels at and which areas they could stand to improve.

3. Assess risks

Risk assessment is an important element of supplier evaluation. You need to know what could potentially compromise your operation – and how to respond if something goes wrong.

Conduct a risk assessment to identify potential risks associated with each supplier. For example, these could be geopolitical risks, natural disasters or financial instability.

Once you’ve identified potential risks, you should develop strategies for how to mitigate them. Not only will this ensure you’re prepared in the event of a disruption – it’ll also quickly show you which suppliers might be more trouble than they’re worth.

Want to learn more about risk assessment? Check out our article: ‘ What is Supplier Risk Management – and how do you benefit? ’

4. Conduct audits and trials

When evaluating suppliers, it’s important to get a proper understanding of how they perform on the daily. There are a few different ways to do this – such as supplier audits and trial orders.

Perform regular audits – both scheduled and surprise audits – to assess supplier performance over time. Pay attention to quality control processes, production capacity and how well the suppliers adhere to delivery schedules.

You can also place trial orders to evaluate how well the suppliers are able to meet your expectations under real-world conditions. This’ll give you a good idea of what an ongoing working relationship with them might look like.

5. Negotiate terms

Your evaluation should set you up for ensuring the most beneficial collaboration. Use your findings to negotiate terms and conditions that’ll protect your interests and help you build solid relationships with your chosen suppliers.

For your terms, make sure to include the nitty-gritty like quality benchmarks, delivery schedules, pricing and penalties for any slip-ups.

6. Review and update

Finally, it’s important to continually review your supplier evaluation process. After all, as your business grows, your needs will change – and so will the market conditions and industry rules and regulations.

Stay up to date with the latest developments, and adjust your evaluation criteria accordingly to make sure they stay relevant and cover all bases.

Supplier evaluation helps you build lasting professional relationships with suppliers that you know you can rely on.

With a good understanding of what supplier evaluation is, why it’s important and how it’s done, you’ll have a solid foundation for getting the most out of your supplier evaluation efforts and ensuring your business relationships last.

Get the Pleo Digest

5 key criteria for evaluating your suppliers

In any supplier evaluation , whether of a new or existing supplier, it’s important to measure the company’s production capacity, performance, risks, quality and environmental impact . However, evaluating these factors on their own will get you nowhere if you don’t have an organized approach to evaluation and a broader framework to make the evaluation information work for you.In this article, we’ll review some of the most crucial factors in conducting supplier evaluations, as well as how to ensure successful evaluations. First, however, we’ll look at why supplier evaluations are important , and how to set up a broader supplier evaluation system to ensure you can get the most out of your evaluation data.

- 1 Why conduct a supplier evaluation?

- 2 Setting up a supplier evaluation system

- 3.1 Production capacity

- 3.2 Quality

- 3.3 Performance

- 3.5 Environmental impact

- 4 How to ensure a successful supplier evaluation

- 5 Visit your supplier’s website

- 6 The benefits of supplier evaluations

Why conduct a supplier evaluation?

A strong supply chain is the backbone of a successful business . Whatever your industry, close working relationships with your suppliers will enable you to streamline production lead times, minimize operating costs and guarantee the quality of your products.Most companies regularly evaluate the performance of their suppliers in search of inefficiencies or growth opportunities to consolidate the supply chain and strengthen supplier relationships . By examining a supplier’s capabilities, technological resources, delivery strategies and general business practices, you can ensure that your partners share your priorities, and can then adjust their operations in the interests of your company’s competitiveness. By doing so, you can significantly reduce your own risks , improve visibility at every stage of operations, and create greater value for your products and services .

Setting up a supplier evaluation system

Evaluating supplier performance should be an integral part of your company’s procurement activities , not a procedure reserved for reviewing new suppliers . A robust supplier evaluation system will regularly assess suppliers, using categories and rankings within those categories to determine procurement strengths and weaknesses.Even for companies that are limited only in the number of suppliers they can use, evaluations help to distinguish which suppliers are to be preferred , as well as identifying areas of potential risk .

The ultimate aim of the system is to monitor the consistency of supplier performance in a way that is integrated with the purchasing process.Supplier performance should include key performance indicators (KPIs) and clear metrics focused on business priorities, including alert measures to show when a supplier is not meeting standards. Buyers should evaluate suppliers every time they call on them, with deadlines for sending feedback after a purchase. Feedback should also be reviewed regularly by the person or group responsible for ranking suppliers. It can be easier to implement software when buyers rate supplier performance , as the final scores can be used to easily rank companies.

These ratings and indicators don’t have to exist only internally, either. It’s important to agree them with your suppliers so that they are aware of expectations and can provide feedback on them. The inclusion of a system for recognizing and rewarding improvement can also help to clarify expectations of them, and motivate them to improve . Common mistakes in supplier evaluation systems include inconsistent use of KPIs and agreed metrics , failure to give suppliers regular feedback on their performance, ignoring supplier feedback in discussions and setting metrics, and the use of confusing metrics and KPIs.

What should be assessed in a supplier evaluation?

Supplier evaluation is largely data-driven. It must therefore be a carefully structured process, focused on quantifiable performance indicators such as delivery times, production costs and stock levels . A standardized set of supplier evaluation criteria provides a necessary frame of reference with which you can assess a supplier’s capabilities and compare them to those of its competitors.However, before evaluating a current or potential supplier, the company needs to set clear expectations for the relationship between them. From the outset, you need to state your objectives clearly , so that the supplier fully understands the obligations involved, and can adjust its operations accordingly if necessary.While the evaluation of a supplier can be based on a number of factors, there are several elements that every company needs to take into account, whatever the industry concerned. Some of these factors include

Production capacity

All supplier evaluations must address the supplier’s capabilities and limitations . A supplier who can’t adapt production to your production cycles won’t do well.

Although it can be difficult to quantify product quality , it should always be a central element in supplier evaluation . ISO 9001 certification remains the industry standard in this area, indicating that the supplier excels in management responsibility, resource management, product realization and measurement, analysis and improvement.

Performance

Your company should ask as many questions as necessary to determine whether a supplier can perform your typical functions . Previous experience with similar companies, relevant recent projects and possible advances on current products or processes are all valid topics for discussion.

Every company invariably faces certain risks, but suppliers should strive to minimize them throughout the supply chain. Examining performance measures such as overall delays, average response time and corrective actions can help you develop a reliable quantitative assessment of the risks posed by a particular supplier .

Environmental impact

Sustainable development is an essential element of a company’s success, for both financial and ethical reasons. The assessment should cover the supplier’s waste management strategies, waste minimization practices and materials procurement procedures , as well as its energy efficiency efforts and protocols for handling hazardous materials .

How to ensure a successful supplier evaluation

While many companies can easily identify the criteria required for supplier evaluation , it can be difficult to follow the practices necessary to ensure its success . The following guidelines can help your company stay focused throughout your evaluation .Establish a timetable . By clearly defining the necessary tasks and setting deadlines for them, you ensure that everyone understands their responsibilities and will strive to complete them correctly and promptly. Provide your suppliers with a concise but detailed questionnaire at the start of the process. The questionnaire should ask for both factual and subjective answers , should solicit only the necessary information, and should not contain questions that the respondent cannot answer .

Visit your supplier’s website

A personal visit to your supplier’s site can confirm the data obtained from the questionnaire, while offering insight into intangible aspects of the supplier’s business, such as workplace culture. It’s also an opportunity to examine the supplier’s quality control strategies, the current state of equipment and the technical skills of the workforce. Make sure the right staff members are involved in the assessment. If you need to evaluate the performance of a Tier 1 supplier , for example, the CFO should probably be involved, as well as purchasing department managers. Be courteous to your supplier . A strong working relationship with your supplier can only improve productivity . Don’t hesitate to congratulate the best-performing suppliers and give them a warning and advice so that they can try to solve the problem before you end your partnership.

The benefits of supplier evaluations

Supplier evaluation criteria are a valuable tool for your company . By carrying them out regularly, your company can better understand its operations, proactively identify opportunities for growth , reduce risk, streamline lead times , eliminate unnecessary expenditure and improve the performance of your suppliers . These competitive advantages cannot be overstated, and while supplier evaluation must, of course, be comprehensive, it need not be difficult . By following the right protocols within a broader framework, it can be a straightforward process for companies and suppliers alike, enabling both to better understand each other’s strengths and weaknesses , and encouraging them to work together to build a stronger, more prosperous partnership .

Want to learn more about our procurement management software Weproc? Contact us or request your free 15-minutes demo below!

Weproc is a SaaS software specialized in digitizing the procurement process of companies. From purchase requests to supplier invoicing, through the validation process, Weproc is designed to simplify the purchase management of SMEs and mid-sized companies by centralizing all purchase-related activities.

You may also like

Year-end discounts and supplier negotiations.

At the end of the year, maximising profits and minimising costs remains a constant objective for all businesses. One effective way of […]

SRM software: improve your supplier relationship

In the business world, customer relations are well established. Whether it’s managing and maintaining customer relationships or knowing how to properly engage […]

The impact of management software on a company’s accounts department

In the age of new information and communication technologies, businesses need to change their approach. Integrating digital technologies into business operations is […]

Recevez chaque mois nos meilleurs articles ! En bonus, nous vous mettons à disposition nos nouveaux modèles de documents en avant première.

Alors, pas mal non ?

- SaaS Solution Weproc

- Free Ressources

- Discover our tool

Call Us (877) 968-7147 Login

Most popular blog categories

- Payroll Tips

- Accounting Tips

- Accountant Professional Tips

Increase Efficiency With a Routine Supplier Evaluation

As a business owner, you likely evaluate your employees’ performance from time to time. But, your employees aren’t the only ones you should be assessing. If you have suppliers you go to for inventory and materials, you need to evaluate their performance, too. To learn more about supplier evaluation and how to evaluate a supplier, read on.

Supplier evaluation process 101

Suppliers and vendors can make or break your company’s success. With good suppliers and vendors, you can streamline business operations, lower risks, and eliminate unnecessary expenses. Not to mention, conducting regular evaluations can help you spot problems and create a more prosperous partnership.

While evaluating your suppliers, consider the following:

- Performance

- Production capacity

So, what all should a supplier assessment include? Before you can start evaluating suppliers, you need to have a game plan. To get started learning how to evaluate suppliers, follow these six steps.

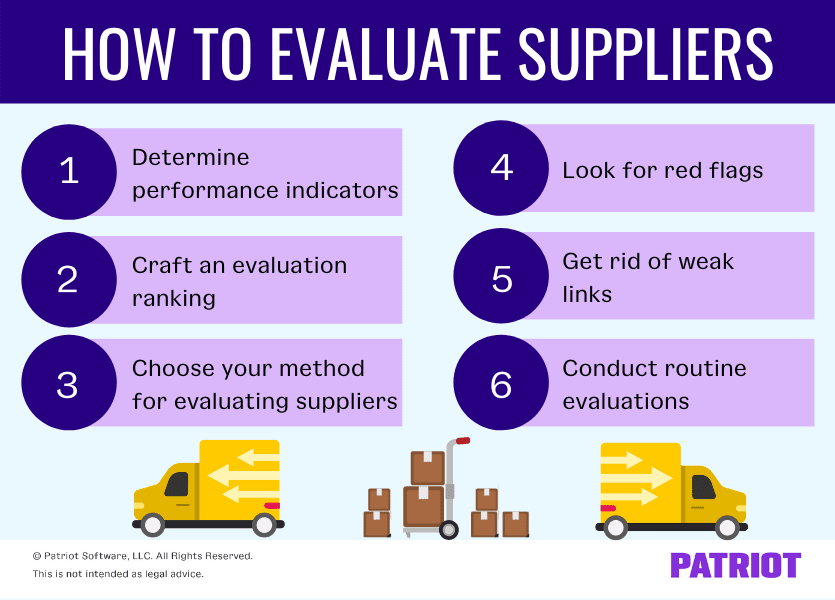

1. Determine performance indicators

To evaluate your suppliers’ performance, you need to determine what you’re going to be rating them on. The metrics you use can vary depending on your type of business and the suppliers you have.

Here are a few examples of performance indicators for vendors:

- On-time performance percentage

- Delivery track record

- Price competitiveness

- Defect rate

- Purchase order and invoice accuracy

- Vendor availability

Again, your performance indicators may vary depending on your business and the supplier. Narrow down what indicators your business will look at when it evaluates suppliers.

2. Craft an evaluation ranking

If your business has a lot of suppliers, it may be easier to evaluate them if you break them down by classification.

For example, you may want to classify suppliers into various categories, such as Level 1, Level 2, and Level 3. The categories allow you to evaluate suppliers using different surveys or methods.

Typically, companies use this step to classify suppliers based on how critical they are to the business.

3. Choose your method for evaluating suppliers

There are a number of supplier evaluation methods to choose from. You may want to use:

- Evaluation forms

- System metrics

Regardless of which method you choose, it’s always good to get feedback from your team. With forms and surveys, you can have employees answer questions about suppliers and vendors and receive honest feedback.

In conjunction with employee feedback, you may also want to gather metrics (e.g., number of products you had to return) to back up claims, especially if the supplier needs to make improvements.

You may want to meet as a team to discuss supplier performance. Or, you may designate a person or small group to go over the feedback and metrics.

4. Look for red flags

There’s nothing worse than dealing with a supplier who performs poorly and doesn’t meet expectations. When going through your evaluations, be on the lookout for supplier red flags. Red flags can include:

- Poor quality products

- Bad business-supplier relationships

- Overpriced products or services

- Poor communication

If you notice some red flags, don’t jump the gun and dissolve the partnership right away. Instead, offer constructive feedback. Discuss your concerns with suppliers who are giving you warning signs. Talk through your problems and use your data to back up your feedback. Consider giving them a warning first before jumping to more drastic actions (e.g., firing your supplier).

5. Get rid of weak links, if necessary

Sometimes, an issue (especially a repetitive one) with a supplier may be the final straw. And in some cases, it may be best to cut ties with an unreliable and underperforming supplier.

If you have discussed performance problems with a supplier and they have not improved, it may be time to end your business relationship with them.

If you have decided to let go of a supplier or vendor, let them know as soon as possible. Communicate with your supplier why you want to cut ties and let them know you would like to end the business relationship.

6. Conduct routine evaluations

Of course, your supplier evaluations shouldn’t occur just once in a blue moon. You should conduct assessments on a regular basis to ensure your business is getting good quality products, minimizing operating costs, and streamlining production timelines.

Conduct routine evaluations regularly, like once a month, quarter, or year. Make sure to inform your team and suppliers about your business’s evaluation schedule so they can prepare.

Need a way to record transactions, like payments made to suppliers and vendors? Give Patriot’s affordable and easy-to-use accounting software a go. With Patriot’s online accounting, you can streamline your books and get back to business. Try it for free today!

This is not intended as legal advice; for more information, please click here.

Stay up to date on the latest accounting tips and training

You may also be interested in:

Need help with accounting? Easy peasy.

Business owners love Patriot’s accounting software.

But don’t just take our word…

Explore the Demo! Start My Free Trial

Relax—run payroll in just 3 easy steps!

Get up and running with free payroll setup, and enjoy free expert support. Try our payroll software in a free, no-obligation 30-day trial.

Relax—pay employees in just 3 steps with Patriot Payroll!

Business owners love Patriot’s award-winning payroll software.

Watch Video Demo!

Watch Video Demo

A Guide for Supplier Evaluation

Supplier Evaluation is a crucial process that assesses the capabilities and risks associated with a supplier, either prospective or existing. The main aim of supplier evaluation is to assist procurement or business teams in making informed decisions on their trade partners and ensure the desired quality of output, align suppliers with business expectations, and minimize any third-party risks that could pose financial, legal, reputational, or regulatory consequences.

The Importance of Supplier Evaluation in Procurement

Having a strong supplier evaluation process is vital for businesses to drive supply chain resiliency and protect the organization from potential risks. The purpose of supplier evaluation is to ensure that the suppliers a business works with have the necessary capabilities to deliver the right products or services on time, as well as maintain sound financial and compliance health. According to research, 87% of surveyed enterprises experience one or more disruptions in their supply chain every year due to issues with suppliers.

87% of surveyed enterprises have resulted in one or more disruptions occurring on an annual basis in their supply chain due to health and compliance issues with their suppliers.

Supplier evaluation is an integral part of a successful supply chain management program and helps businesses mitigate potential risks and improve supply chain resiliency

Steps to Conduct a Comprehensive Supplier Evaluation

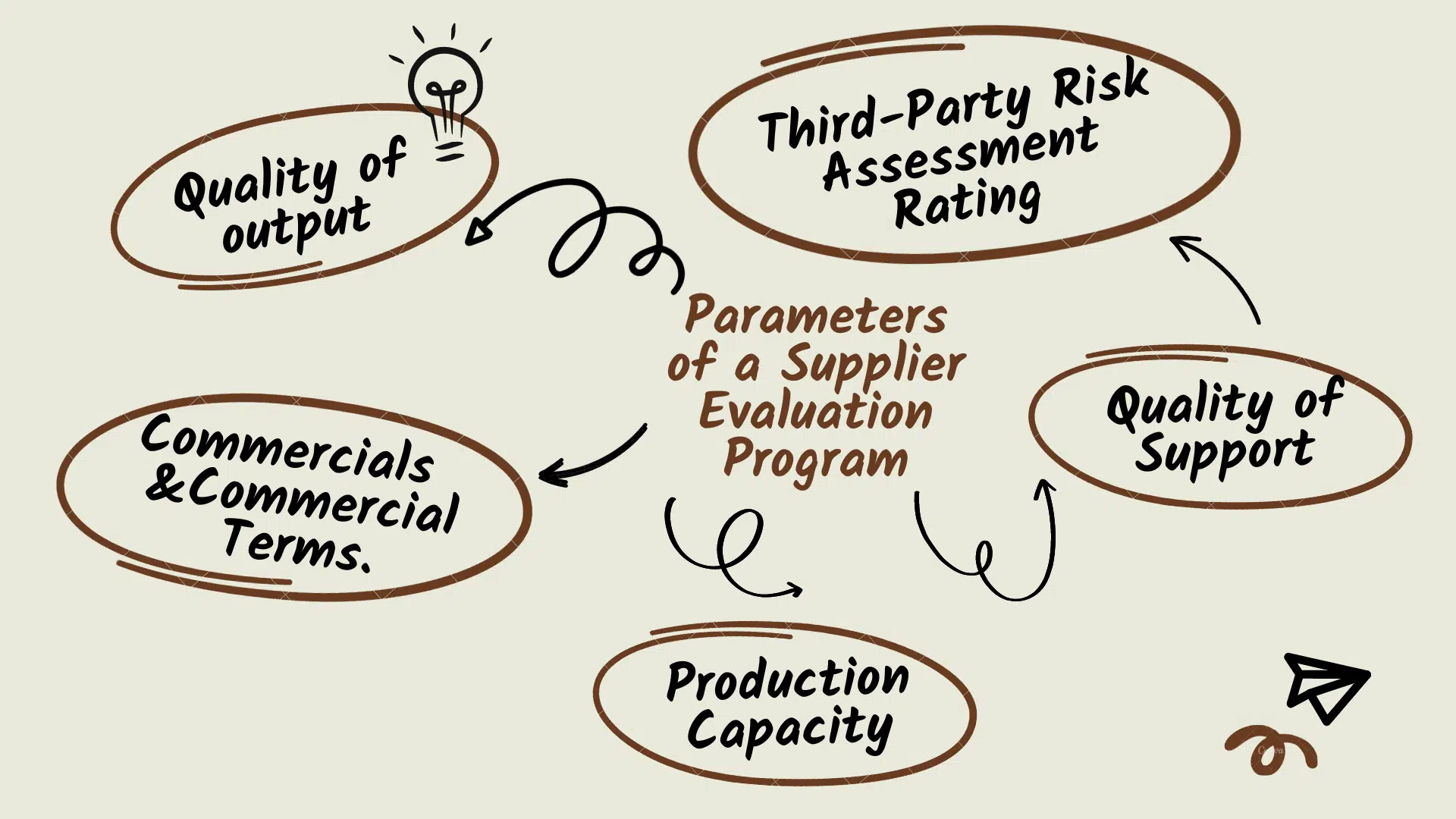

There are four dimensions on which a typical organization may rate their suppliers in their supplier evaluation program. The specific parameters that a business would consider under each may vary from business to business, but the overall dimensions generally remain the same.

The first four dimensions are expectations from functional teams who would be the end users of the supplier’s solutions, and the fifth dimension is that of third-party and sustainability risks which are usually business-level expectations of the quality of supplier that the firm would want to engage with.

An effective supplier evaluation program would generate a simple scorecard by rating suppliers on these five parameters. The ratings can also be done every six months on strategic suppliers and annually across the supply chain. The parameters of a supplier evaluation program are as follows:

- Quality of output Does the quality of the product or service offered by the supplier meet your expectations? The specific metrics that define quality vary from business to business. Detailing the same and assigning a score is the first step toward evaluation.

- Commercials and Commercial Terms. Is the engagement commercially viable for the business? Once you evaluate multiple suppliers on the quality metric, it is required to understand which supplier would be the most effective given the quality.

- Production Capacity As your business grows, your expectation from the customer on the volume of goods and services may scale. It would be an unfortunate situation if there is an influx of customers at your door but a key supplier in the backend is unable to keep up with the demand and deliver on time. Understanding the supplier’s ability to scale his operations is an essential component of supplier evaluation.

- Quality of Support Nothing can be more frustrating than a key supplier not providing the necessary support to address issues that may arise during the engagement. Suppliers’ business priorities may change over time and you would be one of the many customers that the supplier is catering to. Incorporating an assessment of the level of support that a supplier would be willing to provide is a vital part of supplier evaluation processes today. Support-related assessments involve checking if the supplier has a well-defined support process, identifying the level of support the business might require going forward, and setting the sight expectation with the supplier.

- Financial, legal, reputational, and compliance risks Is the supplier financially stressed, is he a belligerent party, and are there economic offenses registered against the supplier or its promoters? Is the supplier a chronic defaulter of tax filings, labor payments, and other essential compliances? How robust are the supplier’s IT systems? Would the supplier expose you to bribery and corruption risks? There is a long list of risks that suppliers expose a business to. The cost of doing business with compromised entities today is steep. Regulators do not hold back when penalizing businesses for transacting with non-compliant entities. Thankfully, the process of generating a TPRM rating is fully automated using AI-driven platforms like SignalX .

- Sustainability Ratings 98% of ESG vulnerabilities that an enterprise faces originate from its supply chain. We have seen businesses surprised on finding suppliers that have been convicted previously of mismanaging hazardous waste and employ practices of harming the environment.

Tools for supplier evaluation

Though it may appear daunting, a supplier evaluation program can be quite simple to execute if planned well. AI-based automation solutions like SignalX.ai takes care of the third-party risk assessment part in its entirety. What is left is collecting information on quality, capacity, commercials, and support. Depending on the type of supplier, this can be done through a field visit to the supplier’s premises, sampling of supplier services, or via collection and verification of certifications and other associated documents from the supplier. Essentially, implementing the following two activities would suffice the execution of an effective supplier evaluation process.

- Sampling, Site Visit, and Audits Sample the supplier’s solution/product and check if it meets your quality checklist. Visit the supplier site, inspect the quality of output, working premises, etc.

- Digital Due Diligence Platform Discreet Checks – Any robust digital due diligence platform can query thousands of sources for financial, legal, compliance, and reputational signals on the supplier and generate a rating. Tools like SignalX.ai’s Vendor Due Diligence automation solutions are inexpensive and produce a report on any target in under 48 hours. Non-discrete collections of Certifications and Disclosures – Leverage a digital platform to collect disclosures and certifications from the supplier. Upload your checklist on a tool like SignalX or create a custom checklist and automate the data collection process and synthesis. This could be on Anti-Bribery and Corruption, Supplier Policies, Certifications such as ISO 27001, ISO 9001, etc, Sustainability Disclosures, and more.

Why evaluating suppliers is critical?

Ever since Henry Ford commercialized the assembly line, and ever since globalization swept across supply chains and transformed systems from being vertically integrated to being interconnected with third parties, efficiency has been at the forefront of business expectations from supply chains.

Today supply chains are the backbone of any enterprise, making it incredibly important to thoroughly evaluate and onboard high-quality suppliers and partners that align with the business’s values and expectations. The supplier Evaluation program allows you to filter and onboard suppliers who can help you maximize business growth with minimal risks.

The following are some of the benefits of implementing a supplier evaluation program.

- Improve end-customer satisfaction and topline Ultimately, a healthy supply chain with partners that are committed to the growth of the business and are well aligned always results in superior quality products being shipped to end customers and a superior customer experience. Unhealthy or compromised suppliers end up causing disruptions and thereby affecting the end customers and bottom line. Supplier evaluation puts quality and compliance at the center of purchasing decisions. In the long run, well-run supplier evaluation programs drive end-customer satisfaction due to sustained maintenance of quality and experience.

- Improve supplier – business alignment Regular supplier evaluation also communicates to suppliers the KPIs that the business is holding them accountable for and also opens a channel for the partners to seek feedback and identify areas of improvement.

- Improve supplier performance Supplier evaluation programs provide valuable information to functional teams and the business to identify areas of improvement, and trends that indicate falling or improving levels of performance, and open a conversation with suppliers about how we might improve such conditions.A well-managed supplier evaluation process also ensures that monies are being put to the best use and there is no redundancy and wastage.

- Improve supply chain resiliency Ongoing supplier evaluation is a necessary activity to identify suppliers with whom relationships may be deteriorating due to poor quality outputs, change in business priorities at the supplier end, or developing third-party risks. These are opportunities for Procurement and Supply Chain teams to plan for identifying alternatives pre-emptively so that no disruptions occur.

What is the purpose of supplier evaluation?

The purpose of supplier evaluation is to assess the capabilities and risks associated with a prospective or existing supplier, in order to make informed decisions on trade partners, ensure desired quality of output, align suppliers with business expectations, and ensure that the supplier is not exposing the business to third-party risks.

What are the dimensions that a business typically considers in their supplier evaluation program?

The dimensions generally considered in a supplier evaluation program include: quality of output, commercials and commercial terms, production capacity, quality of support, and third-party risk assessment rating (TPRM). The specific parameters that a business considers under each dimension may vary depending on the business’s specific needs and expectations.

How often should a supplier evaluation program be conducted?

The frequency of supplier evaluation can vary depending on the business’s needs and the specific suppliers being evaluated. A business may choose to conduct ratings on strategic suppliers every six months, and across the entire supply chain annually. It is also important for businesses to be proactive in monitoring and re-evaluating supplier performance on an ongoing basis, in order to ensure that their supply chain remains robust and resilient.

How can an effective supplier evaluation program help a business protect itself from risks?

An effective supplier evaluation program helps a business understand and mitigate the risks associated with its suppliers. This includes evaluating suppliers for financial and compliance health, assessing their ability to deliver products/services of the desired quality, and ensuring that they are able to scale their operations in response to changing business needs. By proactively identifying and addressing potential risks in the supplier selection and management process, a business can drive supply chain resiliency and protect itself from unexpected disruptions or other negative impacts.

How can SignalX help in Supplier Evaluation?

SignalX is a digital due diligence platform that helps enterprises with discreet (public data) and non-discrete risk assessments on suppliers. SignalX uses a mix of publicly available data such as media records, litigations, corporate records, etc, and disclosures collected via the platform from suppliers to generate a risk portrait on any given supplier which can then be incorporated into any supplier evaluation process.

SignalX’s AI-based automation makes it possible to generate a fully automated third-party risk assessment ratings report in under 48 hours on the given target. The platform also enables enterprises to keep a pulse on their key suppliers and identify developing risks that may be material to the credibility and health of the business. We’re trusted by 200+ enterprises to power their supplier evaluation process.

Request a call to try SignalX today.

Related Posts

Supply Chain Visibility

Exciting announcement: signalx at the 9th tprm india summit 2024.

US Sanctions Target 19 Indian Firms Supporting Russia’s War against Ukraine

Understanding Supplier Management: A Comprehensive Guide

Hit enter to search or ESC to close

IMAGES

VIDEO

COMMENTS

Supplier evaluation is a continual process that involves evaluating and approving potential suppliers. It can also be used to evaluate existing suppliers to monitor their performance, to increase value, mitigate risk and drive improvement. Evaluation can take the form of a questionnaire, interview, or site visit.

Supplier evaluation is a process in which the organization monitors and assesses the performance of its suppliers. The evaluation of suppliers is done either monthly or yearly. The assessment of the supplier includes a review of the supplier’s quality of product or service, price, financial stability, delivery times, and customer service. The ...

Supplier evaluation is the process of assessing and approving potential suppliers through quantitative and qualitative assessments. This is done to ensure you only work with the best-in-class suppliers available. The same process can also be applied to current suppliers to measure and monitor their performance to reduce costs, mitigate risk ...

Evaluating suppliers thoroughly allows companies to identify the best partners, while weeding out poor performers. This leads to reduced costs, improved quality, and better customer satisfaction. The importance of supplier evaluation cannot be understated. It provides the evidence needed to make sound sourcing decisions.

The supplier assessment process is difficult, but identifying low-risk, high-quality suppliers and long-term business connections is worth it. Others benefits of supplier evaluation include: Risk mitigation: Careful supplier screening reduces regulatory, contract, and security risks connected with dealing with external systems.

Trial orders. The goal of supplier evaluation is to assess whether a current or potential supplier is a good match for your business. It allows you to create a best-in-class, low-risk portfolio of available suppliers. In short, supplier evaluation helps you build lasting professional relationships with suppliers that you know you can rely on ...

Supplier development is the process of working with the suppliers whose scores are low, on a one-to-one basis, with the goal of improving their performance. At the end of this process, you should have a detailed plan of action, along with a deadline by which they should implement each change. This is the supplier development program.

3.1 Production capacity. 3.2 Quality. 3.3 Performance. 3.4 Risk. 3.5 Environmental impact. 4 How to ensure a successful supplier evaluation. 5 Visit your supplier’s website. 6 The benefits of supplier evaluations.

Price competitiveness. Lead time. Defect rate. Purchase order and invoice accuracy. Vendor availability. Again, your performance indicators may vary depending on your business and the supplier. Narrow down what indicators your business will look at when it evaluates suppliers. 2. Craft an evaluation ranking.

September 26, 2022. Supplier Evaluation is a crucial process that assesses the capabilities and risks associated with a supplier, either prospective or existing. The main aim of supplier evaluation is to assist procurement or business teams in making informed decisions on their trade partners and ensure the desired quality of output, align ...